Parker Hannifin S.p.A. – S.B.C. Division

quick installation guide Hi-drive

Page 11 of 12

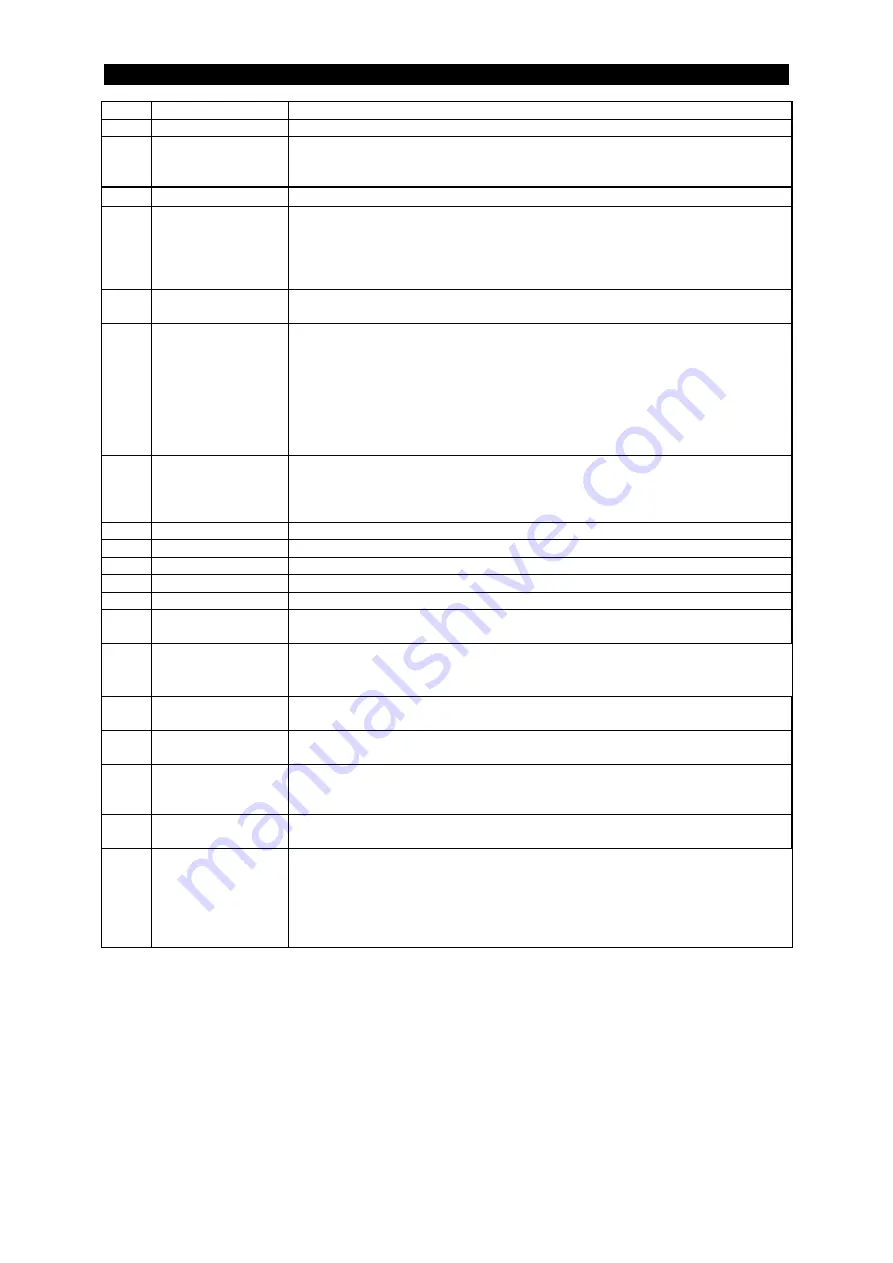

12 Alarms

Pr23 Alarm

Remedies

0 No

alarm

1 Overvoltage

Check

the

three-phase power line.

Check the braking line and braking resistance

Check the application

2 Undervoltage

Check the three-phase power line.

3

Overcurrent

Check any mechanical impediments and correct motor size for required use.

Check motor connections and any short-circuits between phase-phase and phase-

earth.

Check the length and type of motor cable used.

Make sure a mains filter is not connected on the motor!

4

FBK speed loop

error

Check the speed loop connections and the connectors from both sides (drive-

motor).

5

Motor PTC alarm

-Check the PTC connection cable.

-If the alarm persists, disable the drive, interrupt power to the motor, disconnect

the power supply to the drive (24VDC). Disconnect the PTC connector from the

drive, and make a connection short-circuiting the PTC (between PTC+ and PTC-)

on the terminal board of the drive itself.

Power the drive (24VDC). If the alarm continues, the drive is faulty, otherwise

the PTC on board the motor is faulty (after completing the test, remove the

connection short-circuiting the PTC)

6 Power

module

overheating

Check the cooling fans and any blockages/restrictions in air flow.

Check the braking cycle.

Check the room temperature of the switchboard where the drive is fitted and

outside room temperature.

7

External alarm

Depends on application (see PicoPLC program)

8

Auxiliary alarm

Depends on application (see PicoPLC program)

10(*) Check sum PLC

Set the default parameters, save, switch back on and reprogramme the drive

11(*) Check sum param.

Set the default parameters, save, switch back on and reprogramme the drive

15

Default parameters

Set the default parameters, save and switch back on

21 24VDC

undervoltage

The drive power voltage is below minimum threshold: voltage too low.

22 Environment

overheating

Check the cooling fans and any blockages/restrictions in air flow.

Check the room temperature of the switchboard where the drive is fitted and

outside room temperature.

24 Braking

transistor

cutout

Braking resistance in short circuit. If an external braking resistance is connected

to the drive, check its condition and wiring harness.

25(**) Wrong FBK speed

loop initialisation

Check the FBK speed settings.

Check the FBK speed connection.

26(**) Wrong FBK

position loop

initialisation

Check the settings of the position FBK.

Check the connection of the position FBK.

28 FBK

position

loop

error

Check the connections of the position loop and the connectors on both sides

(drive-motor).

I

2

T Current

restriction

(I

2

T) - “the red LED

flashes

continuously”

The drives goes in I²T due to an overload (more power is required than that being

supplied). Check:

-The wiring between the drive and the motor (there must be no switched-over

phases). Above all mind the motors with terminal board rather than connector: it

is easy to make a mistake. Make sure you keep to the wiring diagrams.

- Mechanical sizing

(*) only reset after default loading and new saving.

(**) cannot be reset until next switch-on.

ISBN0411301550