HY28-2668-01/GC/NA,EU

GOLD CUP

®

Series - Application Manual

Piston Pumps & Motors

3.13

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

SERVO

PRESSURE

PRESSURE

COMPENSATOR

FLOW CONTROL

SHOE

CONTROLLED

ORIFICES

PISTON

PIN

TO

OVERRIDE

PRESS.

TO

OVERRIDE

PRESSURE

COMPENSATOR

FLOW CONTROL

PRESS.

PIN

PISTON

Section 3

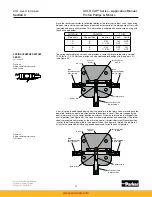

The pump system pressure port (A or B as applicable) is connected to the end of the pin.

When system pressure exceeds 12.25 times the pressure on the end of the piston, the pin

shifts, porting pressure to the cross drilled hole. The cross drilled hole is connected to the

override tube on the pressure side, causing the stroke to reduce. As the stroke reduces,

the shoe controlled orifice reduces in size, increasing the signal pressure until a balance is

obtained.

For operation on the other side of center, the opposite flow control, intensifier piston and shoe

orifice are in control. The first shoe orifice is blocked and servo pressure is applied to the shoe

balance area through that path. By keeping this orifice blocked, the pump is prevented from

limiting while dynamic braking.

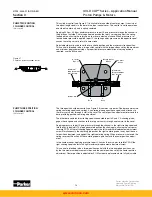

A special designed servo shoe (torque limit override shoe see Figure 3.18) forms the variable

orifice in conjunction with the feedback cover plate. The shoe is carried in the feedback arm

and travels against the control cover. Since the feedback arm is trapped by the bolt heads in

the balance plate (see internal configuration chapter) the torque limit override shoe follows

with pump displacement.

In the control cover, a pair of small holes are located over the torque limit override shoe (see

Figure 3.18). A pair of comet-tail shaped grooves (shown darkened) in the shoe are posi-

tioned so they will travel under one or the other of the holes in the cover plate when the pump

is on stroke. The combination of these holes and grooves forms the variable shoe controlled

orifices.

As the pump moves off of neutral in one direction, one groove travels under its correspond-

ing hole and “opens” the orifice. As the pump increases stroke further, the variable orifice

enlarges. Only one orifice is “open” at a time. The orifice which is open controls an intensifier

valve which is connected to the gage port for the outlet port. The closed orifice is connected to

the low system pressure side and is inactive. When the pump rocker crosses center, the pump

reverses flow and the orifices exchange functions.

By keeping the one orifice closed, the pump is prevented from being torque limited while

dynamic braking.

Figure 3.19 is a simplified drawing of the feedback control cover containing the torque limit

override control. Oil at servo pressure flows from the servo stem through the orifices formed

by the limiter adjusting screws. The pressure drop across these screws is held constant by

the pressure compensator spools downstream of the orifices. The controlled flows pass by the

pistons in the intensifier valves and out the holes in the side covers which connect to the vari-

able orifices. For the side of the control connected to the side of the pump which is pressur-

ized during dynamic braking, the hole in the side cover is connected with servo pressure.This

keeps the corresponding intensifier piston and control pin in the closed mode.

The torque limit override control is contained in the feedback control cover. This allows it to be

used with any of the other control options without further changes to the pump.

Figure 3.18

Torque limit override shoe

Figure 3.17

Torque limit override circuit

www.comoso.com