Bulletin TI-FID1000J

Installation, Operation and Maintenance Manual

Technical Information

FID1000 and 2500 Gas Stations

1-800-343-4048

4

Hydrogen System

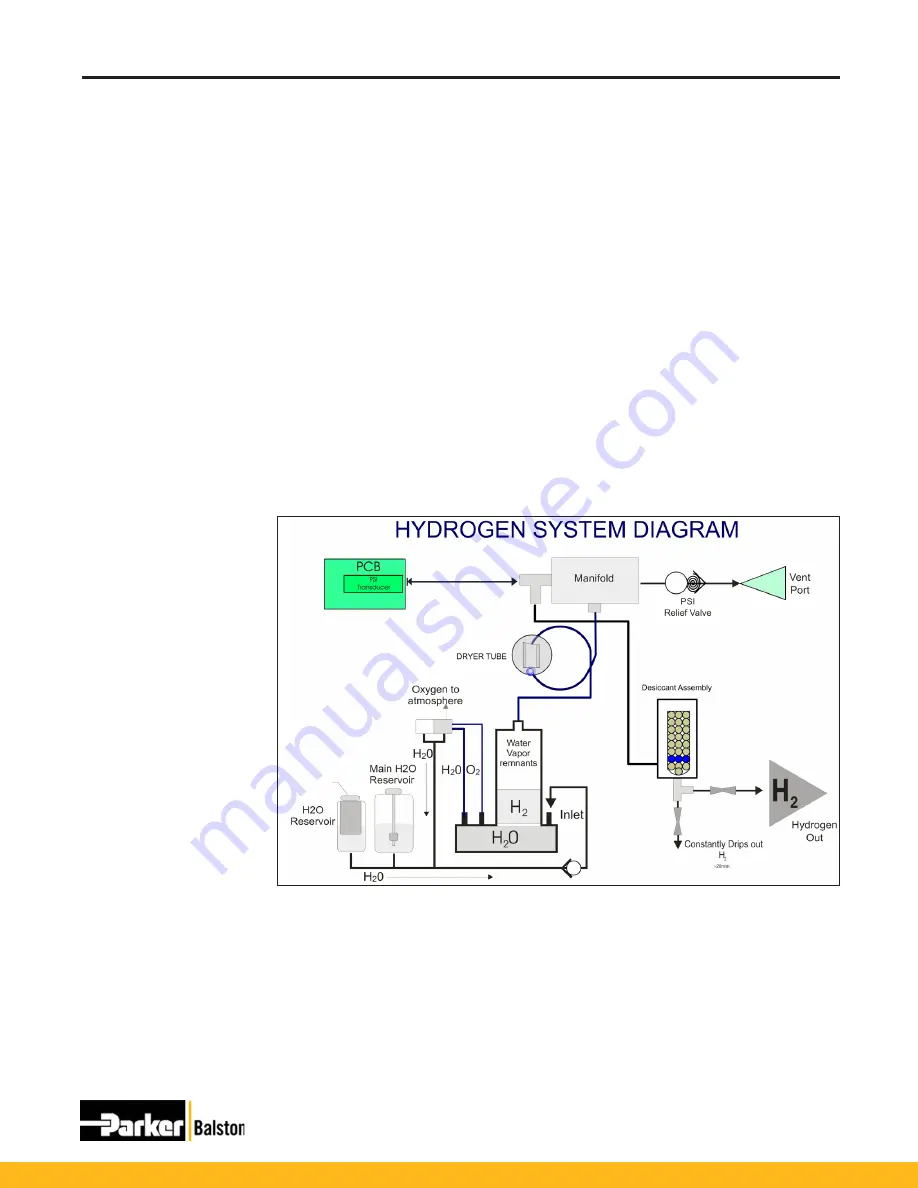

The Parker Balston FID Gas Station also includes a system to generate and purify hydrogen

gas. This portion of the generator includes: water feed system, proton exchange membrane

cell, and desiccant dryer (See figure 3).

The water reservoir for the hydrogen system includes and integral deionizer resin cartridge.

The resin cartridge sets inside the water bottle and all deionized water fed to the system

passes through this resin. The purpose of the cartridge is to ensure good quality (greater than

5 Megohm) water is circulated through the electrolyzer cell. Note: The deionizer cartridge is

not intended to purify tap water.

Electrolysis occurs inside the electrochemical cell assembly (Figure 3). Positively charged

hydrogen ions are transported across the solid polymer electrolyte along with excess water

molecules. The hydrogen ions then recombine to create molecular hydrogen. Negatively

charged oxygen ions recombine to form molecular oxygen. The water saturated oxygen is fed

into a water/oxygen separator, where the water is returned to the water tank, and the oxygen

escapes to the atmosphere. Small deionizer bags in the separator ensure the quality of the

water returned to the water tank.

The final stage of the hydrogen process is purification through the desiccant drying bed. Any

liquid water or moisture carried over in the electrolysis process is removed to purity 99.9995%.

When the desiccant becomes saturated, the orange beads indicating color will turn clear. At

this point, the expended cartridge can be exchanged or regenerated as per the procedure in

the Maintenance section.

Water Feed

PEM Cell

Desiccant Dryer

Figure 3 - Flow Schematic Hydrogen

Deionizer

Resin

Cartridge