Page 21 of 28

Part No. 100318 Rev. 1

Issued: 2021-06-08

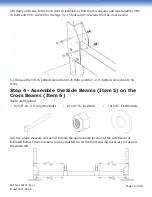

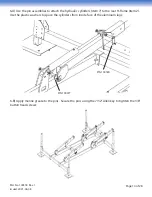

11-B) If two solar panels are being installed, orient the solar panels as shown below with the

black electrical connections approximately 2 inches apart. Mark the locations of the electrical

connections and drill two 7/8” holes at the marked locations. Insert the electrical wires into the

power pack and secure the solar panels using double-sided tape.

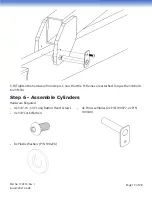

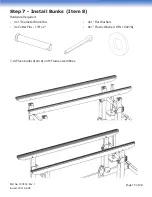

Verify Assembly

CAUTION!

Check that all bolts have been tightened and cotter pins bent.

Be careful when working around hydraulics and battery, wear eye protection.

WARNING!

Check that the hydraulic hose is routed under the side beam and that there

are no pinch points.

Test the lift initially with no load, actuate it several cycles. Verify that no

fittings are leaking and there are no hose pinch points. Apply additional

lubrication to pins if squeaky and tighten any leaking fittings.

10.75”

2”

15.3”

16.3”

3”