5

Palmgren Operating Manual & Parts List

80329

OPERATION

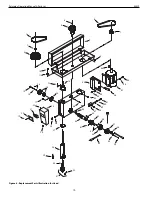

Refer to Figures 4, 5 and 6.

WARNING:

Read and understand operating instructions and

parts manual before operating this machine.

CAUTION:

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in severe eye

damage. Always wear safety glasses complying with United States

ANSI Z87.1 (shown on package) before commencing power tool

operation.

SPEED ADJUSTMENTS

Refer to Figures 4 and 6.

WARNING:

Be sure drill press is turned off and is disconnected

from power source before adjusting speeds.

•

To change spindle speed, loosen motor tension rod (Ref. No. 49)

and set screw of idler pulley (Ref. No. 46). Pivot the motor

toward front of drill press and twist idler pulley (Ref. No. 5) to

loosen front belt. This will permit relocating the belts to the

desired pulley groove for the required spindle speed (See

Figure 4).

•

After belt has been repositioned, pull handle (Ref. No. 56) to

move motor toward rear of drill press and tighten motor ten-

sion rod.

•

Check belt for proper tension and make any final adjustment

(Ref. Nos. 50 and 51). A belt is properly tensioned when light

pressure applied to midpoint of the belt produces about 1/2”

deflection.

TABLE ADJUSTMENTS

WARNING:

Change the radial position of the table only if the drill

press base is secured to the floor. Swinging the table about the col-

umn without the base secured to the floor could cause the drill

press to become unstable and tip over resulting in injury and/or

damage to the machine.

Refer to Figure 5.

•

Height adjustments: To adjust table, loosen locking handle (Ref.

No. 3) and turn crank handle (Ref. Nos. 12 and 13) to desired

height. Immediately retighten table bracket locking handle.

•

Rotation of work table : Loosen table locking handle (Ref. No. 3)

and rotate table (Ref. No. 1) to desired position and retighten

handle.

•

Clamp table securely after adjustments have been made.

DEPTH STOP ADJUSTMENT

Refer to Figure 6.

•

To control drilling depth, loosen locking knob (Ref. No. 36)

inside feed handle hub (Ref. No 37). Rotate graduated collar

(Ref. No. 38) so desired depth is indicated on collar next to the

indicator line (ref. No. 41). Tighten the locking knob. Use this

feature to drill more than one hole to the same depth.

•

Spindle can be locked in either fully or partially down position.

Loosen locking knob (Ref. No. 36). Lower chuck to the desired

depth, rotate graduated collar (Ref. No. 38) fully clockwise and

tighten the locking knob. Use this feature to set up and align

work.

MOUNT DRILL BIT

WARNING:

Be sure drill press is turned off and is disconnected

from power source before adjusting speeds.

•

Place drill bit in jaws of drill chuck.

•

Tighten chuck with drill chuck key. Be sure to tighten the chuck

using all three key positions on the chuck body and remove

chuck key.

Spindle

Rotation

Spindle

Motor

Figure 4 – Spindle Speed Adjustment

D

C

B

A

Z

Y

X

W

4

3

2

1

D4-1W

C3-1W

B2-1W

D4-2X

C3-2X

D4-3Y

B2-3Y

A1-2X

C3-4Z

B2-4Z

A1-3Y

A1-4Z

2600

2060

1540

1220

965

715

420

415

320

240

235

140

in/mm

3/8

9.5

5/8

15.9

7/8

22.2

7/8

22.2

7/8

22.2

1

25.4

1

1

⁄

4

31.8

1

1

⁄

4

31.8

1

5

⁄

8

41.3

1

5

⁄

8

41.3

2

50.8

2

50.8

in/mm

1/4

6.4

3/8

9.5

1/2

12.7

1/2

12.7

1/2

12.7

5/8

15.9

3/4

19.0

3/4

19.0

7/8

22.2

7/8

22.2

1

25.4

1

25.4

in/mm

7/32

5.6

11/32

8.7

15/32 11.9

15/32 11.9

15/32 11.9

9/16

14.3

11/16 17.5

11/16 17.5

3/4

19.0

3/4

19.0

7/8

22.2

7/8

22.2

in/mm

3/16

4.8

5/16

7.9

7/16

11.1

7/16

11.1

7/16

11.1

1/2

12.7

5/8

15.9

5/8

15.9

13/16 20.6

13/16 20.6

1

25.4

1

25.4

in/mm

1/8

3.2

1/4

6.4

11/32 8.7

11/32 8.7

11/32 8.7

7/16 11.1

1/2

12.7

1/2

12.7

5/8

15.9

5/8

15.9

3/4

19.0

3/4

19.0

in/mm

3/32

2.4

5/32

4.0

1/4

6.4

1/4

6.4

1/4

6.4

5/16

7.9

3/8

9.5

3/8

9.5

1/2

12.7

1/2

12.7

5/8

15.9

5/8

15.9

in/mm

1/16

1.6

1/8

3.2

3/16

4.8

3/16

4.8

3/16

4.8

1/4

6.4

5/16

7.9

5/16

7.9

7/16 11.1

7/16 11.1

9/16 14.3

9/16 14.3

in/mm

3/64 1.2

1/16 1.6

1/8

3.2

1/8

3.2

1/8

3.2

3/16 4.8

1/4

6.4

1/4

6.4

3/8

9.5

3/8

9.5

1/2

12.7

1/2

12.7

Belt

Location

RPM

Wood

Zinc

Diecast

Alum. &

Brass

Plastic

Cast Iron

& Bronze

Steel

Mild &

Malleable

Steel Cast &

Med.

Carbon

Steel

Stainless &

Tool