NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

47

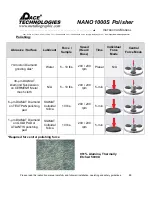

4.8.3.10 CLASS 10: Engineered Ceramics

(Example: Alumina and Sapphire Ceramic)

The preparation of hard / brittle /

porous ceramic materials are not

especially difficult with a few simple

preparation tricks. First, to minimize

grain pull-out (or fracturing in single

crystals) which may be falsely

characterized as porosity sectioning

damage must be minimized. This is

accomplished by sectioning with

the appropriate diamond wafering

blade and using the finest practical

abrasive for initial grinding. Planar

grinding is best achieved with the use of as small a diamond abrasive as possible

on a metal mesh cloth. Note there is a trade-off between planar grinding time

(abrasive size) and induced damage. In some cases, for ceramics, it is better to

take more time and minimize damage at planar grinding in order to reduce overall

polishing times. The use of SIAMAT colloidal silica also provides a chemical

mechanical polishing (CMP) action which is the most effective means for

eliminating both surface and subsurface damage. The combination of SIAMAT

colloidal silica with DIAMAT polycrystalline diamond also produces the required

surfaces finishes.

Sectioning:

Diamond Wafering Blade - Medium Grit / Low Concentration

Mounting:

Castable Mounting with Epoxy or Acrylic resins.