NANO 1000S Polisher

I

NSTRUCTION

M

ANUAL

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] W eb: https://www.metallographic.com

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

24

4.7.3 Final Polishing

The purpose of final polishing is to remove only the cosmetic surface damage. It

should not be used to remove any damage remaining from cutting and planar

grinding. If the damage from these steps is not completely removed, the rough

polishing step should be repeated or continued.

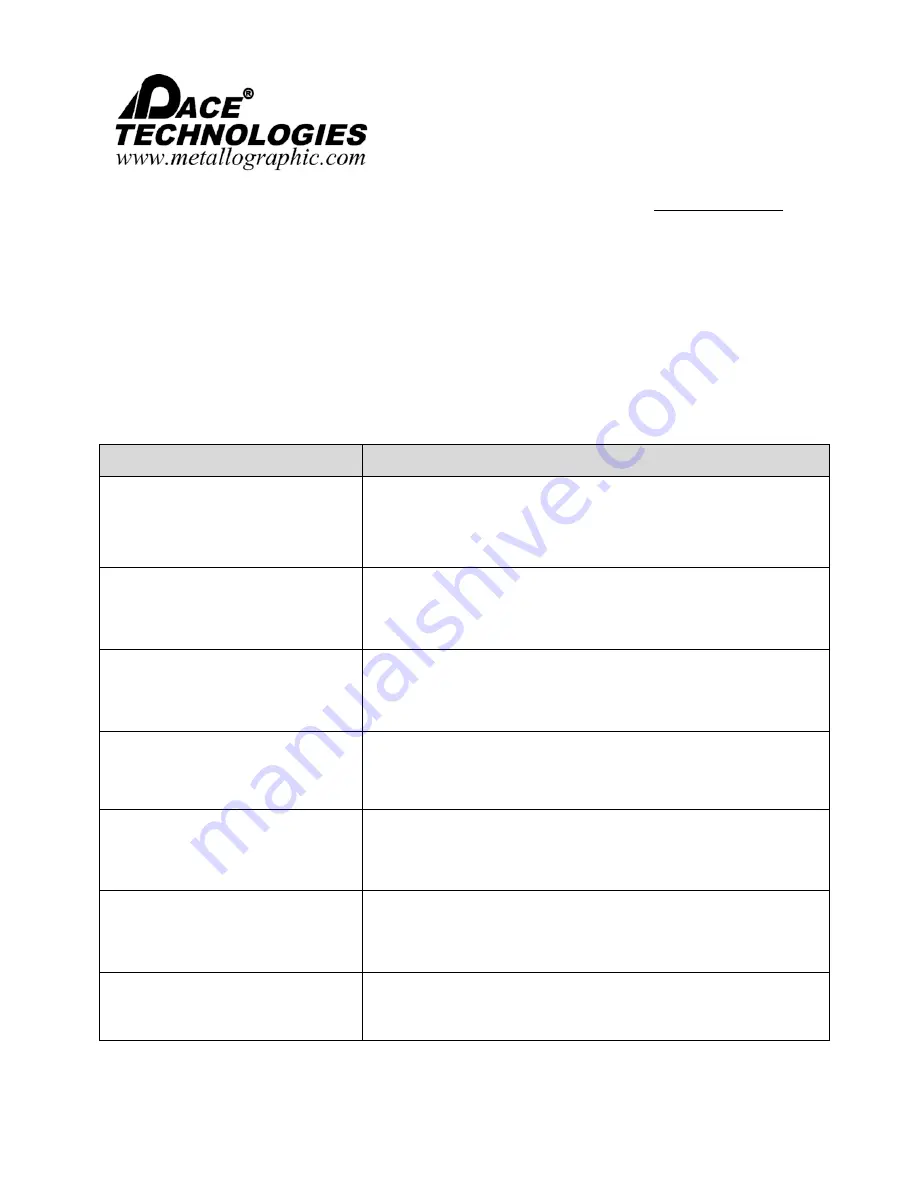

Final Polishing Guidelines

Material

Recommendation

Metals

(Ferrous, Non-ferrous, Tool

Steels, Superalloys, etc.)

High-napped polishing pads with a nanometer

alumina polishing abrasive.

The polishing times should be nominally be less

than 30 seconds.

Ceramics and Ceramic

Matrix Composites (CMC)

Low-napped polishing pads using 1-

μ

m

polycrystalline diamond, alternating with colloidal

silica or colloidal silica alone.

Polymer Matrix Composites

(PMC)

Fine abrasive diamond-lapping films, followed by

a very light polish on a high-napped polishing

pad.

Biomaterials

Low-napped polishing pads with polycrystalline

diamond, alternating with colloidal silica.

Microelectronic Specimens

Diamond-lapping films followed by a very light

polish on a high-napped polishing pad.

Plastics and Polymers

Light polish with alumina on a high-napped

polishing pad.

Plasma Spray Materials

Diamond-lapping films followed by a very light

and short alumina or colloidal silica polish on a

high-napped polishing pad.