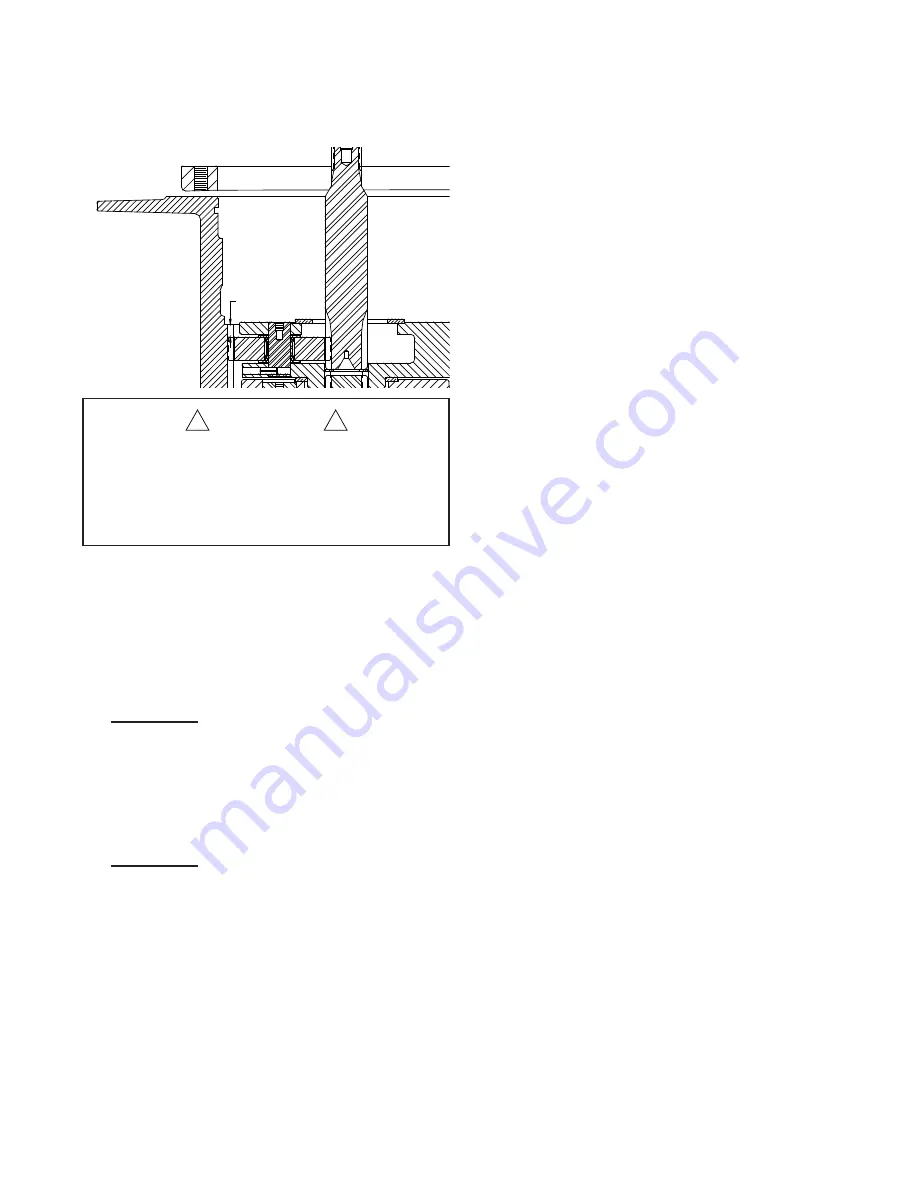

DO NOT

proceed with assembly if the primary

planet gears are not engaged with the ring as

shown in the drawing above. Check the location

of all thrust washers to be sure they are properly

positioned.

10. Install a new bearing in the drum closure if required.

BG8A ONLY:

Apply a nonhardening sealant on the

outside surface of a new oil seal. Install with spring

side of the seal toward the bearing, using a flat

plate to avoid distortion. Install a new O-ring in the

drum.

11. Lubricate the drum opening with petroleum jelly or

gear oil and install the drum closure into the drum.

BG8B ONLY:

Apply a nonhardening sealant on the

outside surface of a new oil seal. Install with spring

side of the seal toward the drum closure, using a

flat plate to avoid distortion.

12. Lubricate the pilot, oil seal and bearing surfaces

of the brake cylinder and carefully install brake

cylinder into base and drum. Be careful that the

brake cylinder pilot fits into the thrust washer on the

primary planet carrier. When correctly installed, the

brake cylinder will fit against the winch base.

13. Install and tighten brake cylinder capscrews and

lockwashers. Tighten to recommended torque.

14. Install the brake clutch assembly.

When installed correctly, the cam should turn freely

in the opposite direction the drum turns to pull wire

rope in. An easy way to check the rotation is to hold

the outer race in one hand, and rotate the cam.

15. If the brake discs are misaligned, preventing the

installation of the clutch, apply 750-1000 PSI

(5170-6900 kPa) to the brake release port with a

hand pump. The brake discs will move freely with

the brake released, permitting alignment of the

discs, brake clutch and input sun gear.

16. Install a new O-ring on the motor pilot then lubri-

cate with petroleum jelly or gear oil. Engage the

motor shaft with the inside race of the brake clutch

and lower motor into place. Install and tighten cap-

screws to recommended torque.

17. Install the hoses and fittings to the brake cylinder

release port, manifold and brake valve.

18. After the winch assembly is complete, check all

capscrews and fittings to make certain they have

been tightened correctly.

Refill the winch with the recommended oil listed

under “Preventive Maintenance,” and install the oil

level plug.

Operate the winch slowly in both directions and

check for oil leaks and/or unusual sounds from the

winch. The winch should operate smoothly in both

directions. Refer to “WIRE AND BRAIDED ROPE

INSTALLATION” and properly install rope onto the

winch drum.

Before returning the winch to full service, a light

load should be lifted and held a few feet off the

ground to be sure the static brake is functioning

properly. The winch should also be able to slowly

lower the load in a smooth and controlled manner.

If the winch does not perform either of these func-

tions, refer to “TROUBLESHOOTING” for additional

information.

26

3/8 inch

9.5 mm)

When all components are correctly installed, the pri-

mary planet gears will be approximately 3/8 inch (9.5

mm) below the ring gear, as shown above. Binding

and damage to the gear train may result if one or

more of the thrust washers is incorrectly installed.

CAUTION

!

!