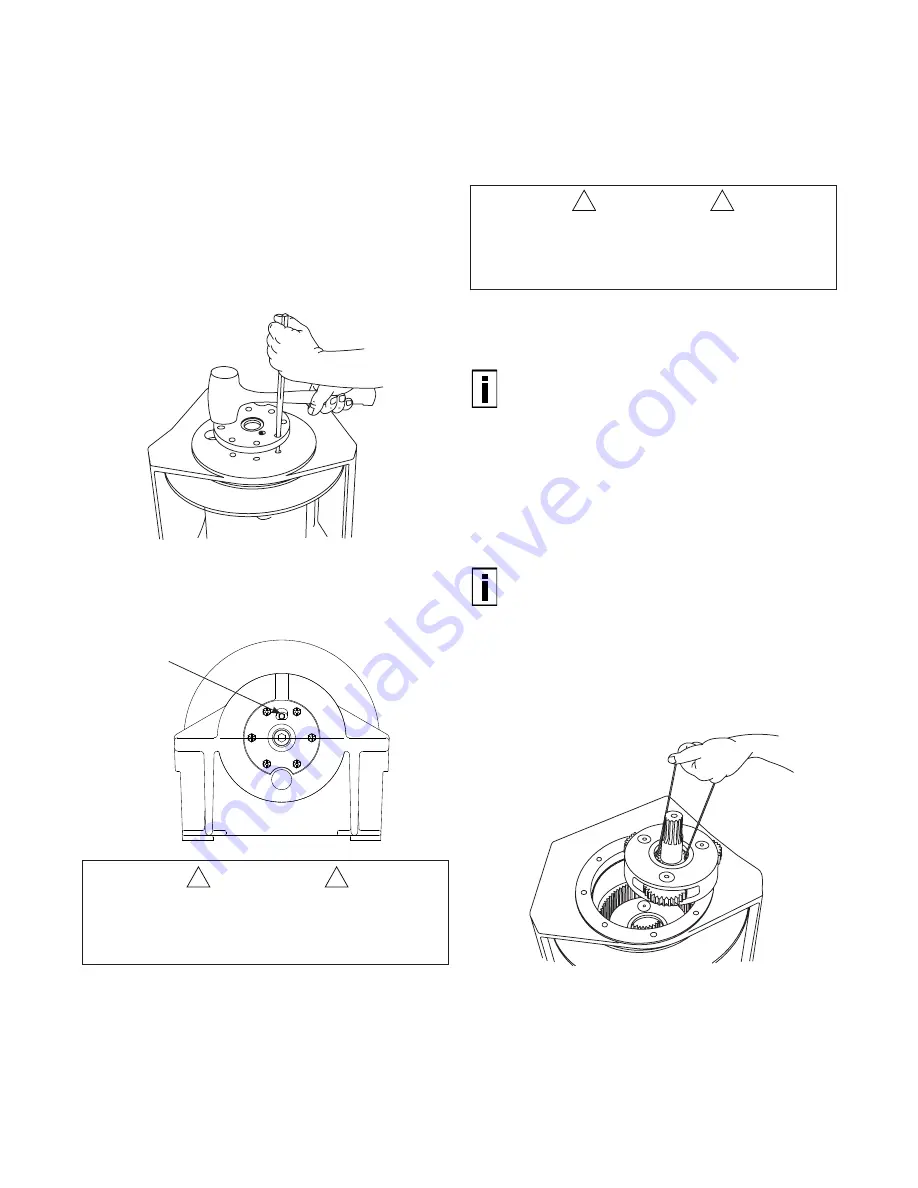

1. Place winch base on side with bearing support end

up.

2. Install a new bearing in the drum if replacement is

necessary. Apply a nonhardening sealant on the

outside diameter of a new seal. Install the spring

side of the seal toward the bearing, then press into

the drum, using a flat plate to avoid distortion. Be

sure drain plug is installed securely.

3. Center the drum in the opening of the base.

Lubricate the bearing support with petroleum jelly

or gear oil and install in base and drum.

4. Tighten the bearing support capscrews to the rec-

ommended torque.

5. Stand winch on bearing support end and install

snap ring on bearing support.

6. Install the output sun gear and thrust washer into

the output planet carrier.

TIP: 2 pieces of stiff wire with an L-shaped hook

on one end can be used to lower the planet carrier

assemblies into the drum.

7. Install the output planet carrier into the drum while

meshing the planet gears with the ring gear and the

planet housing with the bearing support.

8. Install the primary sun gear and thrust washer into

the primary planet carrier.

NOTE:

23:1 gear ratio winches have a sun gear

adapter in addition to sun gear shaft. The thrust

plate between the primary and output sun gears

is not captive within the carrier assembly. Apply

a small amount of oil soluble grease or petroleum

jelly to the thrust plate and center it on the output

sun gear before installing the primary planet car-

rier assembly.

9. Install the primary planet carrier, meshing the plan-

et gears with the ring gear and the planet housing

with the output sun gear.

WINCH ASSEMBLY

Be sure the vent plug is located above the horizontal

centerline for the intended application. Oil leakage

may occur if vent is positioned incorrectly.

25

VENT PLUG

ABOVE CENTERLINE

This snap ring will keep the output planet carrier

correctly positioned in the winch. Gear train damage

may occur if this snap ring is omitted.

CAUTION

!

!

CAUTION

!

!