S8V-CP

14

Recommended Ferrules and Crimping Tools

Recommended Ferrules

Applicable to all the terminal blocks

Note: 1.

Make sure that the outer diameter of the wire is smaller than

the inner diameter of the insulating sleeve of the

recommended ferrule.

2.

Make sure that the ferrule processing dimensions conform

to the following figure.

Power input terminal block

Note: 1.

Make sure that the outer diameter of the wire is smaller than

the inner diameter of the insulating sleeve of the

recommended ferrule.

2.

Make sure that the ferrule processing dimensions conform

to the following figure.

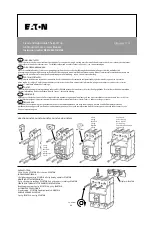

Recommended Flat-blade Screwdriver

Use a flat-blade screwdriver to connect and remove wires. Use the

following flat-blade screwdriver.

The following table shows manufacturers and models as of 2018/Dec.

*

SZF 0-0,4X2,5 (manufactured by Phoenix Contact) is available to

order as OMRON's exclusive purchase model (XW4Z-00B).

Recommended Replacement Periods and Periodic Replacement for

Preventive Maintenance

The recommended replacement period for preventive maintenance is greatly influenced by the installation environment of the Power Supply. As

a guideline, the recommended replacement period is 7 to 10 years.

*

To prevent failures or accidents that can be caused by using a Power Supply beyond its service live, we recommend that you replace the Power

Supply as early as possible within the recommended replacement period. However, bear in mind that the recommended replacement period is for

reference only and does not guarantee the life of the Power Supply.

Many electronic components are used in the Power Supply and the Power Supply depends on the correct operation of these components to

achieve the original Power Supply functions and performance. However, the influence of the ambient temperature on aluminum electrolytic

capacitors is large, and the service life is reduced by half for each 10°C rise in temperature (Arrhenius law). When the capacity reduction life of the

electrolytic capacitor is reached, the Power Supply failures or accidents may occur. We therefore recommend that you replace the Power Supply

periodically to minimize product failures or accidents in advance.

*

The recommended replacement period applies under the following conditions: rated input voltage, load rate of 50% max., ambient temperature

of 40°C max., and the standard mounting method.

This product model is designed with a service life of 10 years minimum under the above conditions.

Applicable

wire

Ferrule

Conduct

or length

(mm)

Stripping

length

(mm)

(Ferrules

used)

Recommended Ferrules

(mm

2

) (AWG)

Phoenix

Contact

Weid

muller

Wago

0.25

24

8

12

AI 0,25-8

H0.25/12 FE-0.25-8N-YE

10

12

AI 0,25-10

---

---

0.34

22

8

12

AI 0,34-8

H0.34/12 FE-0.34-8N-TQ

10

12

AI 0,34-10

---

---

0.50

20

8

12

AI 0,5-8

H0.5/14

FE-0.5-8N-WH

10

12

AI 0,5-10

H0.5/16

FE-0.5-10N-WH

0.75

18

8

12

AI 0,75-8

H0.75/14 FE-0.75-8N-GY

10

12

AI 0,75-10

H0.75/16 FE-0.75-10N-GY

1/1.25 18/17

8

12

AI 1-8

H1.0/14

FE-1.0-8N-RD

10

12

AI 1-10

H1.0/16

FE-1.0-10N-RD

1.25/

1.5

17/16

8

12

AI 1,5-8

H1.5/14

FE-1.5-8N-BK

10

12

AI 1,5-10

H1.5/16

FE-1.5-10N-

BK

2.5

14

10

12

AI 2,5-10

H2.5/

16DS

FE-2.5-10N-

BU

Recommended crimp tool

CRIMPFOX6

CRIMPFOX6T-F

CRIMPFOX10S

PZ6 roto Variocrimp4

8 to 10 mm

2.6 mm max.

2.8 mm max.

Applicable

wire

Ferrule

Conduct

or length

(mm)

Stripping

length

(mm)

(Ferrules

used)

Recommended Ferrules

(mm

2

) (AWG)

Phoenix

Contact

Weid

muller

Wago

4

12

12

14

AI 4-12

H4.0/20D FE-4.0-12N-GY

6

10

12

16

AI 6-12

H6.0/20

FE-6.0-12N-YE

*

Recommended crimp tool

CRIMPFOX6

CRIMPFOX6T-F

CRIMPFOX10S

PZ6 roto

Variocrimp4

*

Use the

Variocrimp16.

Model

Manufacturer

ESD 0,40×2,5

Wera

SZS 0,4×2,5

SZF 0-0,4×2,5

*

Phoenix Contact

0.4×2.5×75 302

Wiha

AEF.2,5×75

Facom

210/-719

Wago

SDIS 0.4×2.5×75

Weidmuller

9900 (-2.5×75)

VESSEL

12 mm

4 mm max.

4 mm max.

0.4 mm

2.5 mm dia.

2.5 mm

Side

Front