S8V-CP

11

Ambient Operating and Storage Environments

• Store the Product at a temperature of

−

25 to 85°C and a humidity

of 5 to 96%.

• The internal parts may occasionally deteriorate or be damaged. Do

not use the Product in areas outside the derating curves.

• Use the Product at a humidity between 5 to 96%.

• Do not use the Product in locations subject to direct sunlight.

• Do not use locations where liquids, foreign matter, or corrosive

gases may enter the interior of the Product.

• If the Product has been accidentally dropped, do not use it as its

internal parts may be damaged.

• Minor electric shock, fire, or Product failure may occasionally

occur. Do not disassemble, modify, or repair the Product or touch

interior of the Product.

Installation Environment

• Do not use the Product in locations subject to shocks or vibrations.

In particular, install the product as far away as possible from

contactors or other devices that are a vibration source. Be sure to

mount End Plates (PFP-M) on both ends of the Product.

• Install the Product well away from any sources of strong, high-

frequency noise and surge.

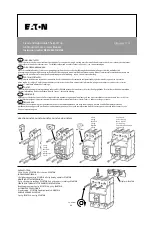

Mounting

• Take adequate measures to ensure proper heat dissipation to

increase the long-term reliability of the Product. Mount the Product

so that air convection will occur around it. Use it in areas within the

derating curves (see

Derating Curves

on page 7).

• The internal parts may occasionally deteriorate and be broken due

to adverse heat radiation.

Do not loosen the screws on the Product.

• Mount as shown below.

• Only products of the same model can be combined and used if the

horizontal separation is less than 15 mm.

Wiring

• The property damage may occasionally occur due to fire If the

insertion distance is not sufficient. When wiring, insert the wiring

material securely all the way in.

• Minor fire may possibly occur. Ensure that input and output

terminals are wired correctly.

• Do not apply more than 40 N force to the terminal block when

inserting wiring or inserting a flat-blade screwdriver into the release

hole.

• Do not wire anything to the release holes.

• Do not tilt or twist a flat-blade screwdriver while it is inserted into a

release hole on the terminal block. The terminal block may be

damaged.

• Insert a flat-blade screwdriver into the release holes at an angle.

The terminal block may be damaged if you insert the screwdriver

straight in.

• Do not allow the flat-blade screwdriver to fall out while it is inserted

into a release hole.

• Do not bend a wire past its natural bending radius or pull on it with

excessive force. Doing so may cause the wire to break.

• Do not insert more than one wire into each terminal insertion hole.

• Do not pre-solder the ends of the wires. Doing so will inhibit proper

connection.

• If there is a possibility that the Unit will be subject to vibration or

shock, use Wires with Ferrules or Stranded Wires.

• Be sure to remove the sheet covering the product before Turn ON

so that it does not interfere with heat dissipation.

• To prevent wiring materials from smoking or ignition, confirm wire

ratings and use the wiring materials given in the following table.

Recommended Wire

• Use copper stranded wire or solid wire.

• Do not use the solid wire to the power input terminal.

• Use min. 75°C wire.

• Input crossover wiring can be used for the input side of the Product.

If you use crossover wiring for N number of the Products, a current

that is N times the current for a

standalone the Unit may flow to the

input terminals. Take this into consideration when you select

wiring materials.

• Make sure that the current of the power input terminal does not

exceed 35A per pole.

• When connecting to the two poles of the power input terminals, be

sure that the length and

thickness of wires are the same to allow

for well balanced current flows.

Precautions for Safe Use

*

2

*

2

*

1

*

1

*

1

*

1

*

1

*

1

*1.

Direction of air circulation

*2.

Space above and below

the Product: 25 mm min.

(S8V-CP0424

@

)

Space above and below

the Product: 20 mm min.

(S8V-CP0824)

Terminal

Recommended wire gauge

(mm

2

)

(AWG)

Power input terminals

0.25 to 6

24 to 10

Output terminals, Negative input

terminal, Reset signal input

terminal, Alarm output terminal

0.25 to 2.5

24 to 14