All Installations:

6. Install the filter cartridge in the Cartridge Tank.

7. Lubricate the tank O-Ring with vegetable oil or a good grade of

silicone grease and install it in the O-Ring groove.

8. Screw the filter tank back onto the filter head. Hand-tighten the

tank. DO NOT OVER TIGHTEN.

9. To avoid flooding and water damage, make sure that the

O-Ring between the filter head and the tank is in good condition

and properly seated in its groove when reassembling the unit.

10. Slowly open the main water supply valve and check for leaks. If

any fittings or joints leak, slowly turn off the water supply valve

and gently tighten the leaking fitting. Slowly turn the water sup-

ply back on and recheck for leaks.

NOTICE:

If the tank O-ring leaks after you have tightened the

tank hand tight, DO NOT tighten it anymore. Instead, loosen it

and make sure that the cartridge is seated over the center tube in

the head assembly (not pushing against it). After centering the

cartridge, re-tighten the tank and again check for leaks. If the unit

still leaks, tighten the tank 1/4 turn at a time with the wrench

that was supplied with the filter. Recheck for leaks after each 1/4

turn. DO NOT OVERTIGHTEN!

11. Depress the pressure relief button on the top of the head assem-

bly to release any excess air.

12. Open the faucet and flush the filter for at least 10 minutes after

installation to remove the trapped air. Flush the unit for at least

10 seconds every time you use water for drinking or cooking,

especially if the water tap is not used daily.

WHEN TO CHANGE THE CARTRIDGE

The cartridge’s life depends on the water volume used and the sub-

stances in the water. Normally the cartridge should be changed at

intervals of ninety days or less. Replace it sooner if the water pres-

sure at the faucet begins to drop noticeably or if you notice changes

in the taste, color, or flow of the filtered water.

NOTICE:

Certain types of harmless bacteria will attack cellulose materi-

al. Cartridges containing cellulose may seem to disintegrate, produce a

“sewer” or “rotten egg” odor, or form a black precipitate due to bac-

teria. If this happens, consult OMNIFILTER Customer Service for advice.

PROCEDURE FOR CARTRIDGE CHANGE

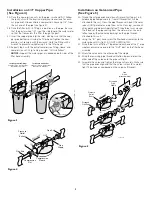

1. Place a pan under the unit to catch any spilled water.

2. Turn the water to the filter off.

3. Fit the wrench onto the ribs of the tank and turn it slowly to the

left to release the pressure and loosen the tank.

4. Support the tank as you unscrew it. Pour out the water from the

tank and remove and discard the old cartridge. Wipe the inside

of the tank clean and dry with a soft cloth.

5. Insert a new cartridge into the tank, making sure that it seats

over the center post on the tank bottom.

6. Lubricate the tank O-ring with vegetable oil or a good grade of

silicone grease and check it for damage. If cut, scratched, or

stretched, replace it with a new one.

7. Screw the filter tank back onto the filter head. Hand-tighten the

tank. DO NOT OVER TIGHTEN. If the unit still leaks, the wrench

supplied with the filter may be used to tighten the tank 1/4 turn

at a time.

8. Slowly turn the water supply on.

9. Open a faucet for about 10 minutes to allow any accumulation

of air, fines, etc., to flush out.

NOTICE:

Use only genuine OMNIFILTER replacement cartridges for

best results. Failure to use OMNIFILTER replacement cartridges will

void your warranty.

10.Depress the pressure relief button on the top of the head assem-

bly to release any excess air.

For further operating, installation, or

maintenance assistance:

Call Omnifilter Customer Service

at 800-937-6664

4

The Omnifilter Models OB1 and

OB5 are Tested and Certified by

NSF International against

ANSI/NSF Standard 42 for

materials and structural integrity

requirements only.

NOTE:

*Omnifilter Models R12 and R14 are not

tested and certified by NSF.