2

NOTICES

Carefully read and follow instructions.

Use the unit only in ambient air temperatures of 35–100° F

(2–38° C) and water temperatures of 35–100°F (2–38° C).

This installation must comply with all applicable state and local

regulations.

Do not use with water that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after the system.

Do not expose the unit to direct sunlight or use this unit outdoors.

Do not use electrical heating tape on this unit.

Do not use pipe compound (“pipe dope”), sticks, or similar com-

pounds with this unit; they contain petroleum derivatives which will

cause crazing and cracking of the plastic in the filter.

Do not use aerosol sprays (bug spray, cleaning fluids, etc.) near the

filter; they contain organic solvents which will cause crazing and

cracking of the plastic in the filter.

Use only Teflon

TM

tape without adhesive backing to seal joints.

Use only soap and water to clean filter housing and components.

Change the cartridge every 3 months (or more often if you notice a

sustained drop in water pressure or a change in the taste of the

water). Follow the “Procedure For Cartridge Change” when chang-

ing cartridges. Use only OMNIFILTER replacement cartridges.

Install the unit vertically (with cartridge tank pointing down) ahead

of the hot water heater. Allow 3” clearance below the cartridge

tank to allow for changing the cartridge.

DO NOT use a torch near the unit.

This unit is designed for non-commercial use on cold water lines only.

Wear safety glasses during installation.

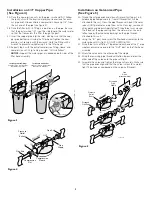

Risk of electrical shock. If your water pipes are

used to ground your house’s electrical system, install a No. 8

AWG (8.4mm

2

) jumper wire (or larger) around the filter (see

Figure 1). The jumper wire must be connected at both ends by

a pressure wire fitting or other connection that satisfies NEC

or CEC and local codes.

Consult a building inspector or licensed

electrician for more information.

PERFORMANCE DATA

Operating Pressure: . . . . . . . . . . . . . . . .25–125 psi (172–862 kPa)

Operating Temperature: . . . . . . . . . . . . . . .35°–100° F (2°–38° C)

Rated Flow: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 gpm (19 lpm)

INSTALLATION INSTRUCTIONS

Tools and Fittings Needed:

For Installation with Copper Pipe:

• Tubing cutter (preferred) or hacksaw to cut into pipes

• 10” Adjustable wrench or 1-1/4” open end wrench to tighten

locknuts

For Installation with Galvanized Pipe:

• 1 Union plus a 2” Nipple

• Pipe cutter or hacksaw to cut into pipes

• Pipe wrenches to tighten union and nipple

• Pipe threader (some hardware stores will thread pipe for you at

purchase – one approach would be to remove one section of pipe

and purchase two sections for reinstallation that, together, meas-

ure 8” shorter than the piece you removed.)

• Paint thinner or solvent (NOT gasoline) to clean new threads

• Teflon

TM

tape without adhesive backing for sealing joints.

All Installations

1. Separate the head assembly from the tank cartridge and set the

tank aside. See Figure 2.

2. Install the fittings or the valves you have selected into the head

assembly. Wrap three turns of Teflon

TM

tape around each end of

the 2” nipple Use Teflon™ tape without adhesive backing for

sealing the joints. Do not overtighten the fittings.

3. Turn off the main water supply valve and open a faucet on the

lowest level of your home to drain the system.

4. Cut out the correct length of pipe. Use a pipe cutter or hacksaw.

File or sand the ends of the pipe to make sure they are smooth

and square. See Figure 3.

NOTICE:

Have a bucket handy to catch any water that may come

out of the pipe.

5. For an installation with copper pipe, go to Step 5A, under

“Installation on 3/4” Copper Pipe”. For a Galvanized Pipe

Installation, go to Step 5A, under “Installation on Galvanized

Pipe”.

TM

E.I. DuPont de Nemours, and Company, Corporation, Wilmington, Delaware.

Figure 1

Filter Head Assembly

Tank Cartridge

Figure 2