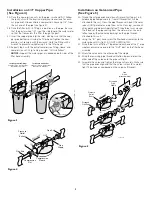

Installation on 3/4” Copper Pipe:

(See Figure 4)

5A. Place the compression nuts on the pipe, small end first. Follow

the lock nuts with the brass compression sleeves (one for each

cut pipe end). Slide each brass compression sleeve up 1/4” from

the cut end of the pipe (see Figure 4).

5B. Place the filter (with its fittings) in position on the pipe. Be sure

that the port marked “IN” is on the side toward the water meter

so that the flow enters the filter through this port.

5C. Insert the copper pipe into the inlet, making sure that the cop-

per pipe bottoms out inside the filter head. Tighten the com-

pression nut securely with the wrench. Hold the fitting with a

wrench to prevent overtightening it in the filter head.

5D. Repeat Step 3 with the outlet compression fitting, sleeve, and

compression nut. Skip to Step 6 under “All Installations”.

NOTICE:

Support the water pipes as needed on both sides of the

filter head assembly.

Installation on Galvanized Pipe:

(See Figure 5)

5A. Thread the cut pipe ends and clean all traces of cutting oil, rust,

hardened pipe compound, etc., from all threads that will be

attached to the unit. Clean the pipe threads with paint thinner or

solvent (NOT gasoline) and dry them with a clean rag; remove all

chips; polish and deburr. Apply Teflon™ tape three turns around

the threads of the pipe coming from the water meter. Use only

teflon tape (without adhesive backing) on the pipe threads

attached to this unit.

5B. Using the “IN” port, hand screw the filterhead assembly onto the

water pipe until it is tight. DO NOT OVERTIGHTEN.

5C. Wrap three turns of Teflon™ tape around each end of the 2” pipe

nipple and screw one end into the “OUT” port on the filter head

assembly.

5D. Screw the union onto the other end of the nipple.

5E. Wrap the remaining pipe thread with teflon tape and screw the

other side of the union onto the pipe until tight.

5F. Assemble the union and tighten the large nut securely. Make sure

that the pipe ends align and that the union is clean for a water-

tight fit (no tape or compound on the union-half threads).

Pipe End

Pipe End

Pipe

Nipple

Water Flo

w

IN

OUT

Compression

Nut

Compression

Sleeve

1/4"

Pressure

Relief

Button

Figure 4

3

Installation with Valves

Length of Pipe to be Cut Out

Shoulder to Shoulder

Installation with Fittings

Length of Pipe to be Cut Out

Shoulder to Shoulder

Shoulder of Valve

Figure 3

Wrapped

Pipe End

Pipe

Union

(disassembled)

Wrapped

Pipe

Nipple

Water Flo

w

4159 0302

IN

Pressure

Relief

Button

OUT

Figure 5