TROUBLESHOOTING

Note:

If you experience an unusual problem that is not described in this section, or if troubleshooting procedures will not

restore the unit to normal operation, please contact Omega.

M4110/

IP211, EP211 SERIES

0519

A

7

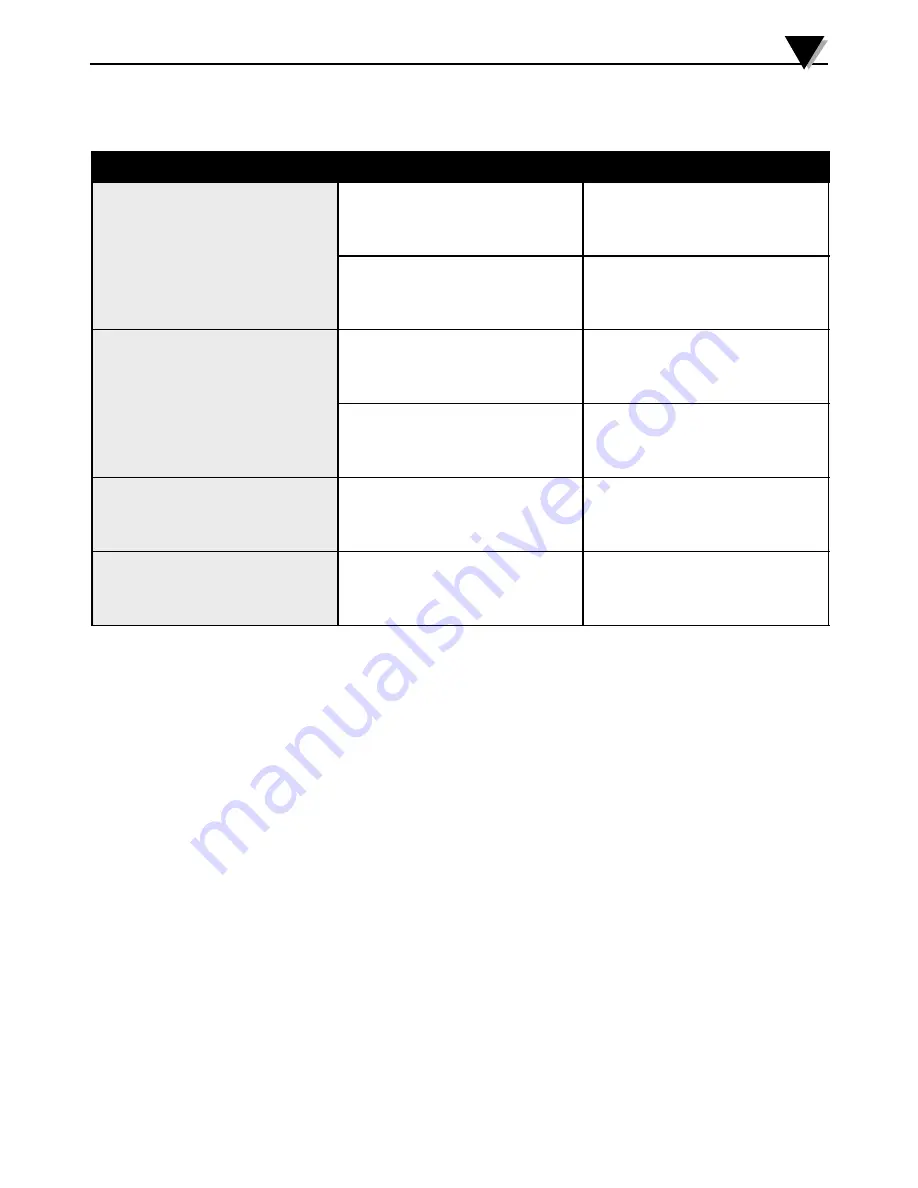

SYMPTOM

CAUSE

SOLUTION

1) Plugged or blocked orifice.

1) Remove orifice screw and clean

orifice with wire or pin <0.009"

diameter

2) Supply pressure too low.

2) Supply pressure must be at least 5

PSIG above the 100% output.

1) Zero set too low.

1) Turn zero adjustment counter-

clockwise until output pressure

increases then follow calibration

procedure.

2) Electrical connection has opened or

wrong type of signal applied.

2) Check electrical connections to

insure that there is a correct input

signal reaching the transducer.

Wires connected in reverse

Insure wiring is connected per Electrical

Connection section.

Pneumatic connections reversed or

supply and output both connected to

“IN” ports.

Insure supply is connected to port

marked “IN” and output is connected to

port marked “OUT”.

Sluggish Performance or Reduced

Range

Transducer remains at start up no

matter the input signal3.

Transducer works in reverse.

(Pressure goes down when input

signal goes up.)

Output Pressure same as supply

Pressure with no signal effect.