23

400715D-EN

Maintenance Schedule

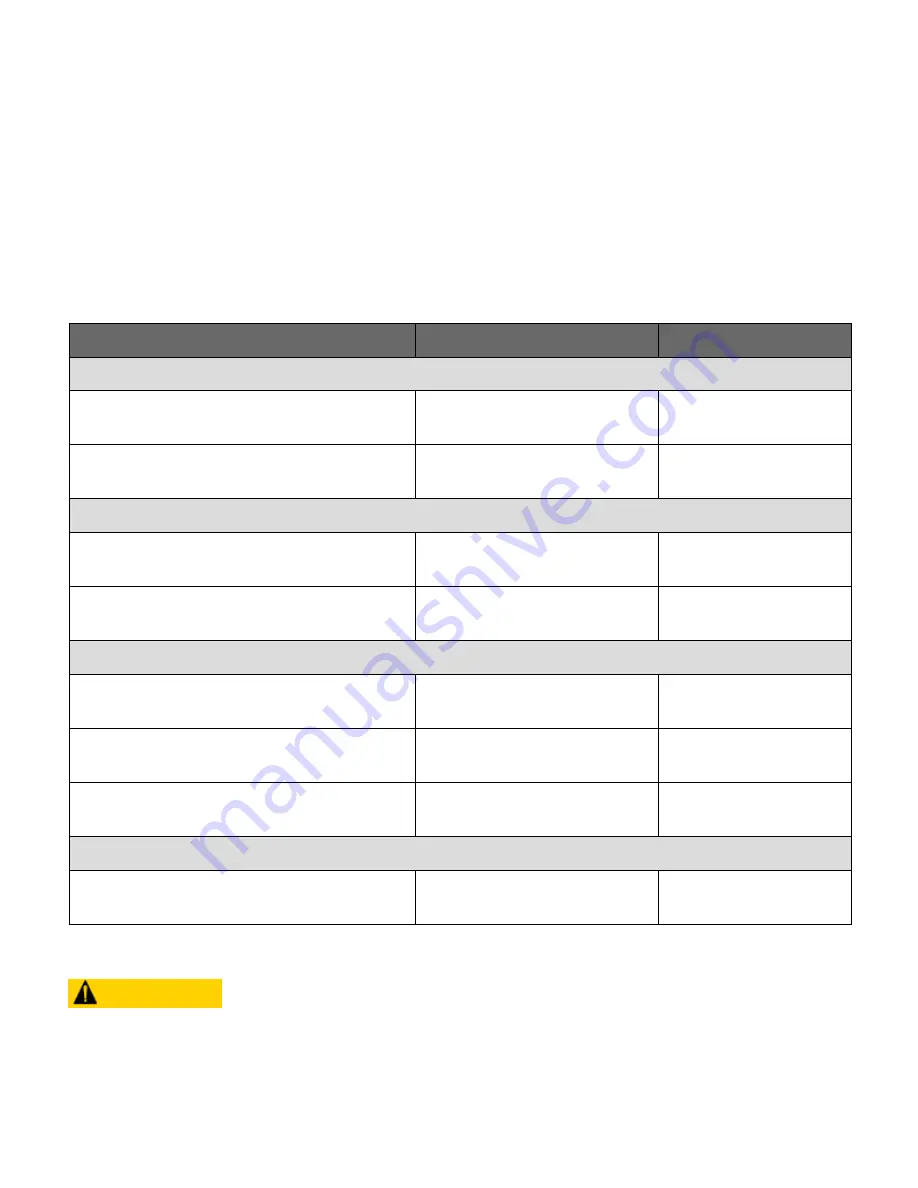

Use the following maintenance activities and schedule to develop a successful equipment maintenance program.

Reference documents and videos provide instructions for performing the specific task.

NOTE

• The expected life of components varies based on specific use cases and environmental conditions.

• The hours listed in this schedule for recommended maintenance are NOT warranty hours.

• The filter assembly and mixing tube vary with equipment.

OMAX MAXJET 5i Nozzle Maintenance

MAXIEM MAXJET 5i Nozzle Maintenance

.

Task

Frequency

Reference

Nozzle Body

Clean the nozzle body to prevent mineral buildup in

the jewel assembly

Every 40 hours

Clean and Examine the

Nozzle Body

Replace the nozzle body

Every 500 hours or when cutting

performance degrades

Remove the Nozzle

Install the Nozzle

Mixing Tube

Rotate the nozzle mixing tube 90 degrees (one-

quarter turn) to even out the wear

Every 8 hours of cutting

Clean or replace the mixing tube

As needed

Remove the Mixing Tube

Install the Mixing Tube

Filters and seals

Replace the final filter assembly (plastic)

Every 40 hours, or more frequently

as needed

Replace the Final Filter

Assembly

Clean the metal filter screen

Every 40 hours, or more frequently

as needed

Clean the Metal Screen

Filter Assembly

Examine the ring seal assembly for damage

Replace as needed

Clean the Metal Screen

Filter Assembly

Abrasive Tube

Examine the abrasive tubing (hopper to nozzle)

Daily, replace as needed

Do an Inspection of the

Abrasive Feed Tube

Prepare For Maintenance

CAUTION

Before performing service on the equipment, turn the air supply to the system OFF and bleed the entire

pneumatic system to make sure it is exhausted of air pressure, including any accessories. Failure to

release the pressure may result in injury.

Summary of Contents for MAXJET 5i 320303 Series

Page 32: ...32 400715D EN...