12

5.

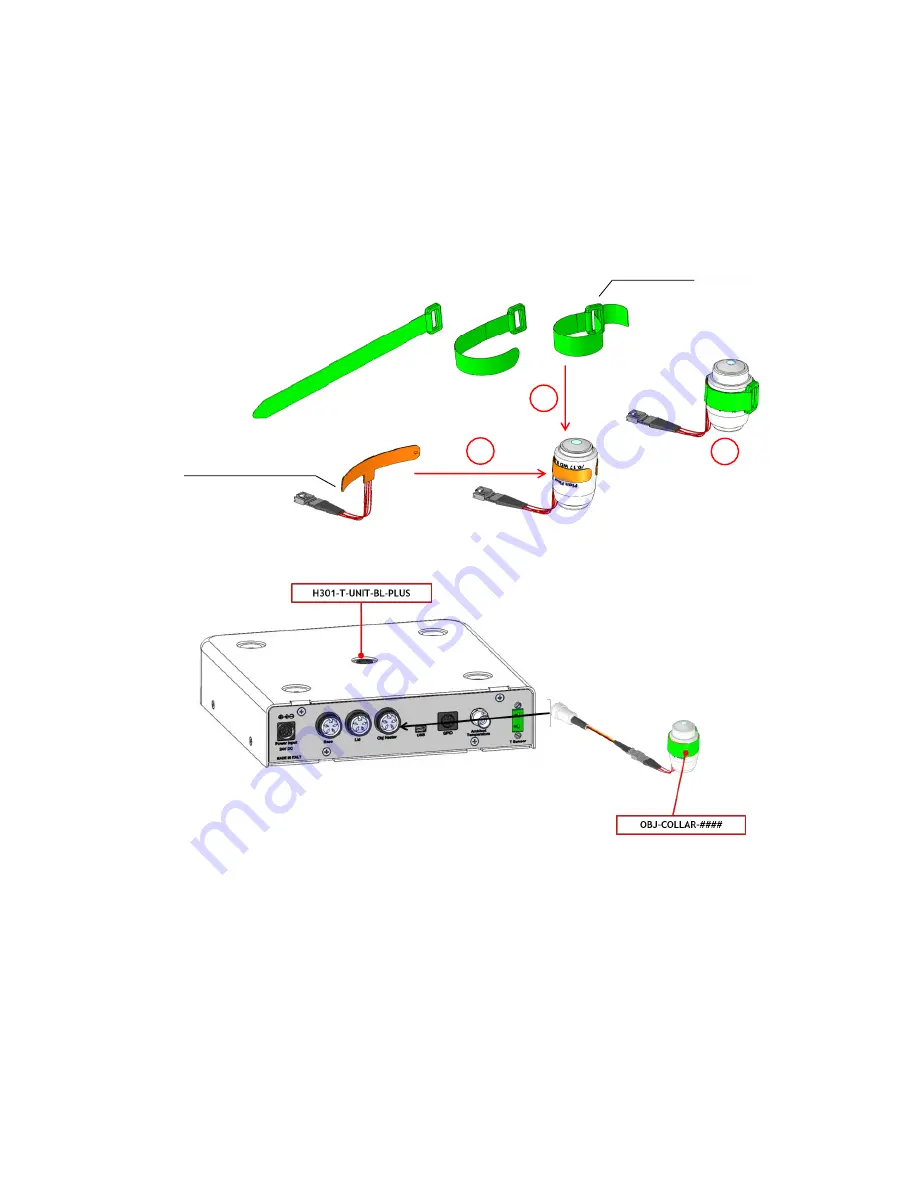

When using oil immersion objectives an Objective Heater should also be purchased. If your system is

also equipped with the Objective Heater, (OBJ-COLLAR ####, optional) its objective collar should be

installed before connecting the heater to rear panel of the Temperature Control Unit. Follow the

steps shown in Figure 3. Once you have assembled it,

plug it into the port labeled ‘Obj. Heater’

located on the rear panel of the Temperature Control Unit (see Figure 4).

Figure 3.Objective Heater (OBJ-COLLAR ####) Assembly

Figure 4. OBJ-COLLAR Connection (Optional)

6.

Connect the touch screen interface OKO-TOUCH to the Temperature Control Unit using the serial

cable provided (see Figure 5).

2

1

3

Objective Band Heater

Velcro Tape