- 7 -

Precautions about the Installation Environment

and Location to Install the Machine

[Precautions related to installation]

WARNING

z

Do not install the equipment in a location that is

near open flame or may become very hot.

z

Do not install the equipment in a location prone

to chemical reactions (laboratory, etc.).

z

Do not install the equipment in a location that is

near flammable liquids, such as alcohol or paint

thinner.

z

Do not install the equipment in a location that is

accessible by small children.

z

Do not install the equipment in a location that is

unstable (on a wobbly table or inclined place).

z

Do not install the equipment in direct sunlight or

in a very dusty or humid location.

z

Do not install the equipment in an environment

subject to salt air, NOx, SOx or corrosive gases.

z

Do not install the equipment in a location that is

subject to excessive vibration.

z

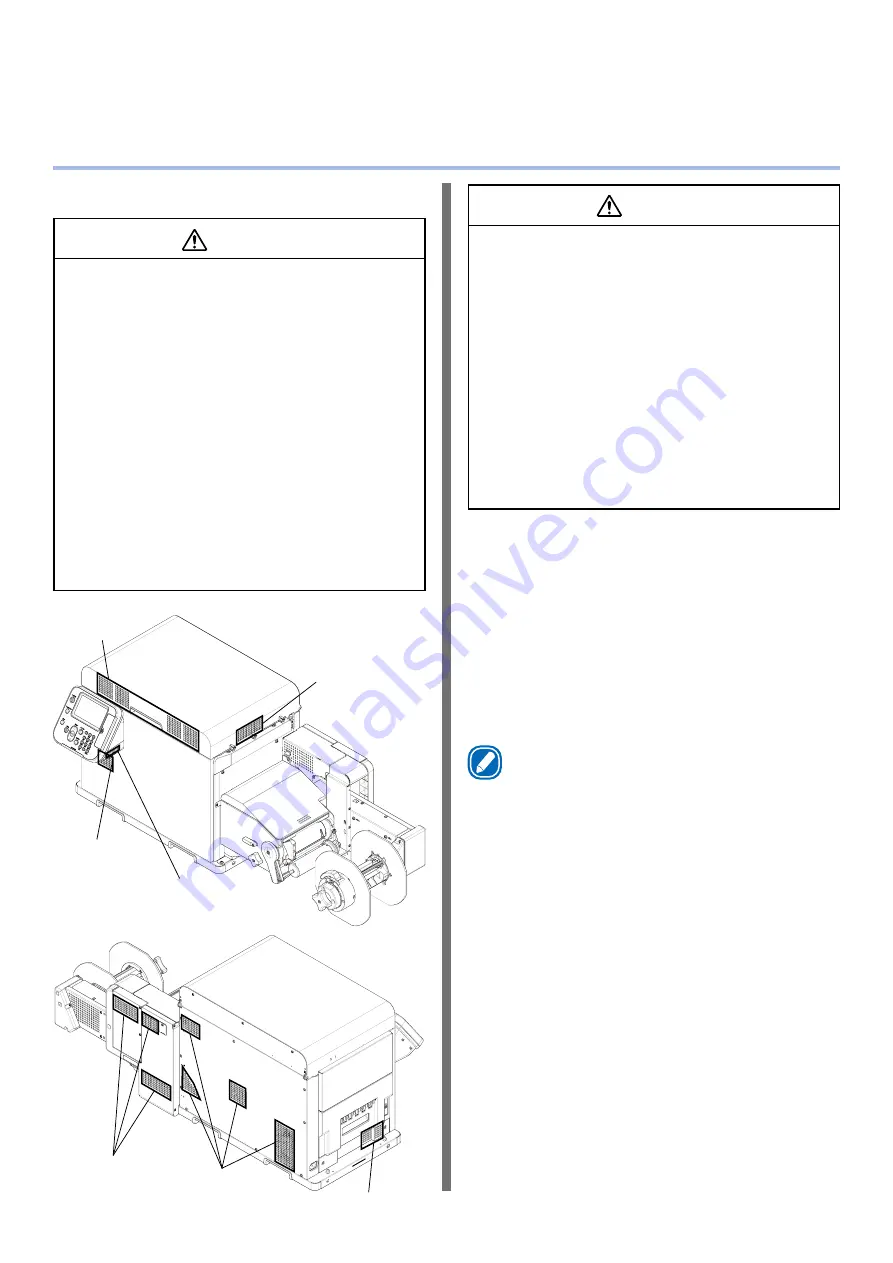

Do not install the equipment in a location where

the machine’s vents are blocked. Check the

positions of the vents in the following illustration.

Front of printer's

top cover

Right side of

printer's top

cover

Front of printer

Control panel

Left side of printer

Back of printer

Back of unwinder

CAUTION

z

Do not install the equipment on a thick-piled

carpet or rug.

z

Do not install the equipment in a location that is

poorly ventilated or stuffy.

z

Pay attention to ventilation when operating the

equipment continuously for a long period in a

small room.

z

Install the equipment away from sources of strong

magnetic or electric noise.

z

Install the equipment away from monitors or

televisions.

z

Remember to use ventilation when printing large

volumes or operating the equipment continuously

for a long period.

z

The machine’s acoustic power level exceeds 6.3B,

so we recommend that it be installed in a room

separate from office work areas.

Consider the following environment conditions

when you select the installation location.

[Installation Environment]

Use a location that is within the following ranges

for temperature and humidity.

Temperature range:

10 to 30 ºC

Humidity range:

20 to 70% RH

(relative humidity)

Maximum wet-bulb

temperature:

25 ºC

Memo

z

Be careful that condensation does not form.

z

If you install the equipment in a location where the

humidity is in a range of less than 30%, use a humidifier

or anti-static mat.