Officine Gullo

22

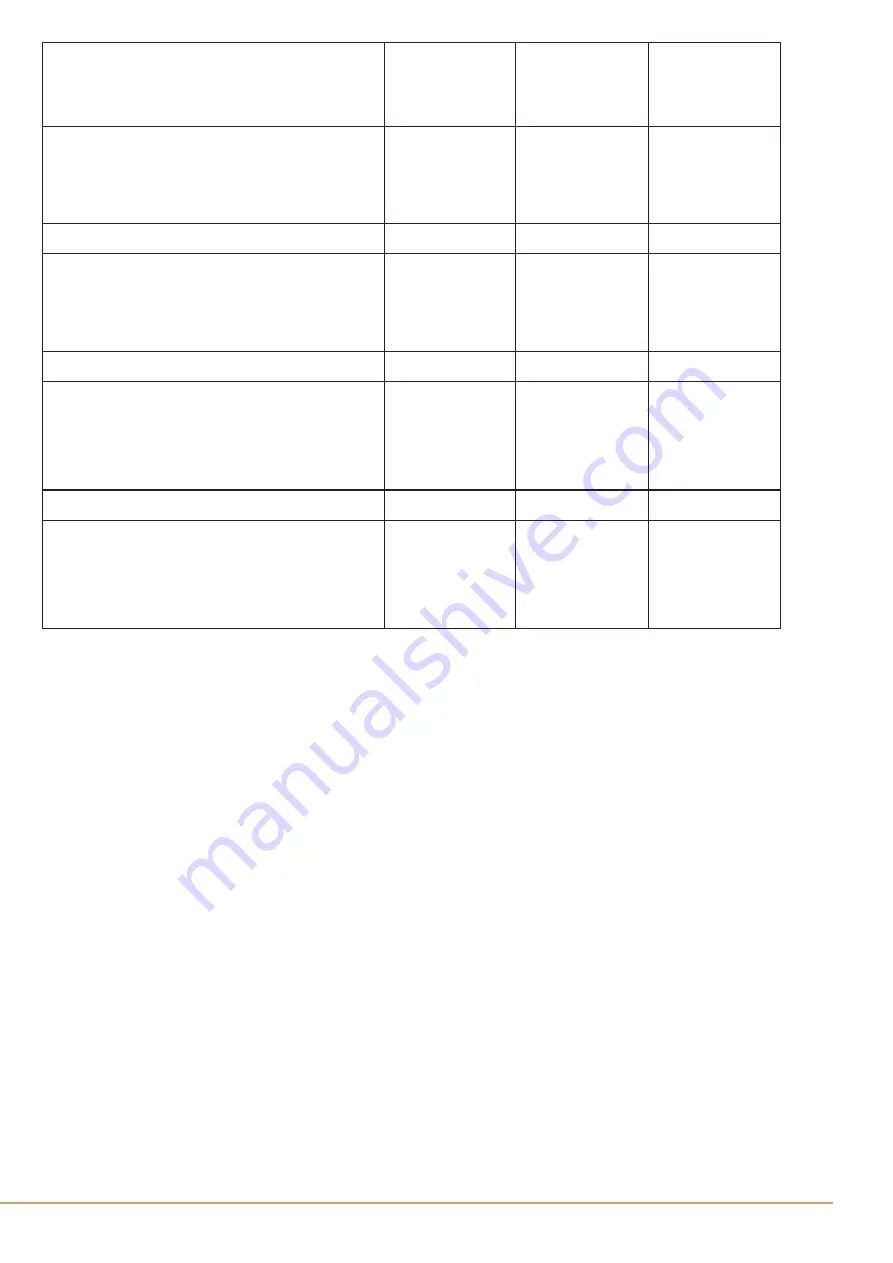

Burner max 3,5 kW- min. 1,15 kW

G110

8 mbar

G150.1

8 mbar

Town gas

G110

10 mbar

Injector (marking)

By-pass (screw asjustment (number of turns anti-

clockwise from fully closed position)

Air adjustment (mm)

250

1/2

11,0

250

1/2

11,0

235

1/2

11,0

Burner max 5,5 kW- min. 1,55 kW

Injector (marking)

By-pass (screw asjustment (number of turns anti-

clockwise from fully closed position)

Air adjustment (mm)

340

3/4

8,5

340

3/4

8,5

320

3/4

8,5

Burner max 7,5 kW- min. 2,5 kW

Injector (marking)

By-pass (screw asjustment (number of turns anti-

clockwise from fully closed position)

Air adjustment (mm)

450

1+1/2

10,0

450

1+1/2

10,0

390

3+1/2

10,0

Oven Burner max 6,5 kW- min. 2,2 kW

Injector (marking)

By-pass (screw asjustment (number of turns anti-

clockwise from fully closed position)

Air adjustment (mm)

Pilot injector

500

2

14,0

50

500

2

14,0

50

450

2

14,0

50

23

Officine Gullo

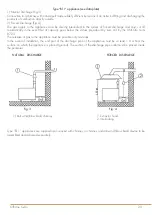

RULES FOR CONVERTING AND INSTALLING OTHER TYPES OF GAS

Our appliances are tested and regulated for liquid gas.

The conversion or adaptation to another type of gas must be carried out by a specialized technician. The nozzles

for the various types of gas are in a packet supplied with the appliance and are marked in hundredths of mm (see

the technical data table).

CHANGING THE OPEN RING NOZZLES

Main nozzles

Take the rungs off, remove the burners and trays, with a size 12 spanner substitute the nozzles with the appropriate ones, regulate

the primary air (h) (see the “burner” technical data table) unscrewing the securing screw. Once regulated, tighten the screw, adjust

the minimum flame by turning the screw to the right or left until the thermal power reaches 1,15 kW for the 3,5 kW burner, 1,55

for the 5,5 kW burner and 2,5 kW for the 7 kW burner.

Warning:

If liquid gas is being used the minimum adjustment screw must be locked right down.

SUBSTITUTING THE NOZZLE IN THE OVEN BURNER

To substitute the oven burner, proceed as follows:

•

Remove the oven bottom (floor);

•

Unscrew the fixing screws from the burner nozzle protection.

•

Substitute the nozzle, using a suitable spanner (see “burners” technical data table).

•

Regulate the air regulation bush to the corresponding value in the “technical data” table by unscrewing the

fixing screw with relative jam nut, regulate minimum output by turning the screw to the right or to the left until the

thermal power reaches 2,2 kW for the burner of 7,3 kW and 3,5 kW for the burner of 11 kW; this procedure

is only possible after having let the oven burner work at maximum output for about 20 minutes (knob in pos.

300).

•

After this procedure, put back the burner nozzle protection.

•

Substitute the pilot nozzle, using a suitable spanner.

After regulating, check lighting, at both maximum and minimum output. Make sure that, when changing rapidly

from minimum to maximum output, the flame does not present any problems and that it doesn’t go out, when

closing or opening the oven door quickly.

Warning:

For functioning with liquid gas, screw down the regulating screw completely.

SUBSTITUTING THE NOZZLE IN THE COUP DE FEU BURNER

Remove the panel and with a suitable spanner substitute the nozzle with another, suitable one.

Adjust the minimum flame by turning the by-pass screw either to the right or to the left until heat output reaches 4 kW.

The primary air of the all plate burner does not need adjusting.

Attention:

If liquid gas is used, the minimum flame adjustment screw must be screwed right down.

Summary of Contents for GGS8P

Page 2: ......

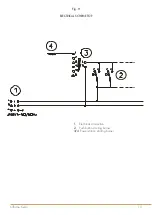

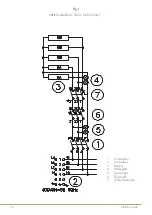

Page 4: ...Officine Gullo 4 E Electrical Connection G Gas Connection INSTALLATION MANUAL Fig A 1 GES8P ...

Page 5: ...5 Officine Gullo E Electrical Connection G Gas Connection Fig A 2 GES12P ...

Page 6: ...Officine Gullo 6 E Electrical Connection G Gas Connection Fig A 3 GEPS8P ...

Page 7: ...7 Officine Gullo E Electrical Connection G Gas Connection Fig A 4 GEPS12P ...

Page 8: ...Officine Gullo 8 E Electrical Connection G Gas Connection Fig A 5 GGS8P ...

Page 9: ...9 Officine Gullo E Electrical Connection G Gas Connection Fig A 6 GGS12P ...

Page 10: ...Officine Gullo 10 E Electrical Connection G Gas Connection Fig A 7 GGPS8P ...

Page 11: ...11 Officine Gullo E Electrical Connection G Gas Connection Fig A 8 GGPS12P ...

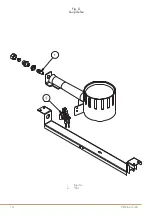

Page 14: ...Officine Gullo 14 Fig G Coup de feu 1 Injector 2 Pilot ...

Page 30: ...Officine Gullo 30 ...

Page 31: ...31 Officine Gullo ...