19

Officine Gullo

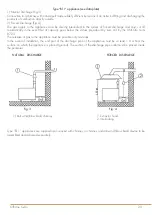

CHECKING FOR ADEQUATE VENTILATION

Make sure that the air intake into the room where the appliance is installed is sufficient for an adequate change of air, as

specified by regulations in effect.

The appliances installed in buildings open to the public must satisfy the following requirements.

Installation rules

The installation and maintenance of the appliance must be done according to the correct procedures and regulation

texts in use, particularly:

• safety standards for the prevention of fire and panic.

Connection and installation of appliance, ventilation and exhaust removal systems, shall be done according to the

Manufacturer’s instructions and by qualified technicians and according to the regulations in effect. The electric wiring shall

conform to the regulations in effect.

All fire prevention codes shall be observed.

a) General indications

(Rules valid for GB only)

- For all appliances:

Gas safety Regulations, 1984; Health and safety at Work Act, 1974 Codes of Practice, BS 8173, 1982, The Building

Regulations 1985; The Building Standards Regulations, 1981, the IEE Regulations and the by-laws of the local Water

Undertaking.

The local gas Region or LPG supplier and the local authority and the relevant recommendation of the British Standards

(latest editions) concerned.

The installation, transformation and repair of appliances for professional kitchens as well as removal due to malfunction,

and the supply of gas, may be made only by means of a maintenance contract stipulated with an authorized sales office

and in observance of technical regulations.

The appliance can be installed by itself or in a series side by side with appliances produced by us.

There must be a minimum distance of at least 10 cm between the appliance and the sides of the nearby cabinets made

of inflammable material.

Take suitable measures to guarantee thermal insulation of the inflammable sides, such as, for example, the installation of

protection against radiation.

The appliances must be installed in a suitable manner, observing the safety standards.

The small feet are adjustable to level the appliance.

PIPE FOR GAS CONNECTION

The gas connection must be done with steel or copper pipes, or otherwise with flexible steel pipes in compliance

with the national norms, if any exist. Each appliance must be provided with a cut-off cock for rapid interruption of the

gas supply. Once the appliance has been installed, it is necessary to check for gas leaks for the pipe fittings; do not

use a flame for this purpose but a non-corrosive substance such as soapy water or foamy substances as contained

in leakfinder sprays. All our appliances undergo careful testing: the type of gas, the operating pressure and the

category are indicated on the data plate.

NB:

The year of the appliance manufacture is shown in item “N” on the data plate. The first two numbers (e.g. 08..)

represent the year of manufacture.

Summary of Contents for GGS8P

Page 2: ......

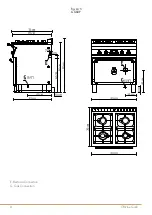

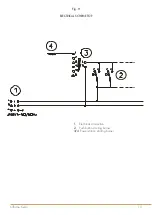

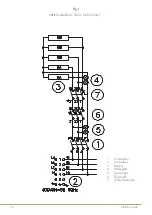

Page 4: ...Officine Gullo 4 E Electrical Connection G Gas Connection INSTALLATION MANUAL Fig A 1 GES8P ...

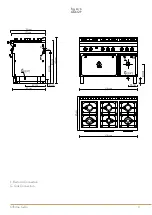

Page 5: ...5 Officine Gullo E Electrical Connection G Gas Connection Fig A 2 GES12P ...

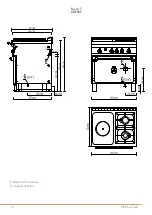

Page 6: ...Officine Gullo 6 E Electrical Connection G Gas Connection Fig A 3 GEPS8P ...

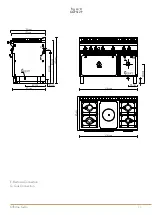

Page 7: ...7 Officine Gullo E Electrical Connection G Gas Connection Fig A 4 GEPS12P ...

Page 8: ...Officine Gullo 8 E Electrical Connection G Gas Connection Fig A 5 GGS8P ...

Page 9: ...9 Officine Gullo E Electrical Connection G Gas Connection Fig A 6 GGS12P ...

Page 10: ...Officine Gullo 10 E Electrical Connection G Gas Connection Fig A 7 GGPS8P ...

Page 11: ...11 Officine Gullo E Electrical Connection G Gas Connection Fig A 8 GGPS12P ...

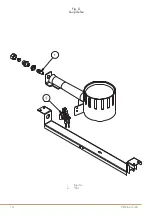

Page 14: ...Officine Gullo 14 Fig G Coup de feu 1 Injector 2 Pilot ...

Page 30: ...Officine Gullo 30 ...

Page 31: ...31 Officine Gullo ...