~ 8 ~

UBZ-304

NOVATEK-ELECTRO

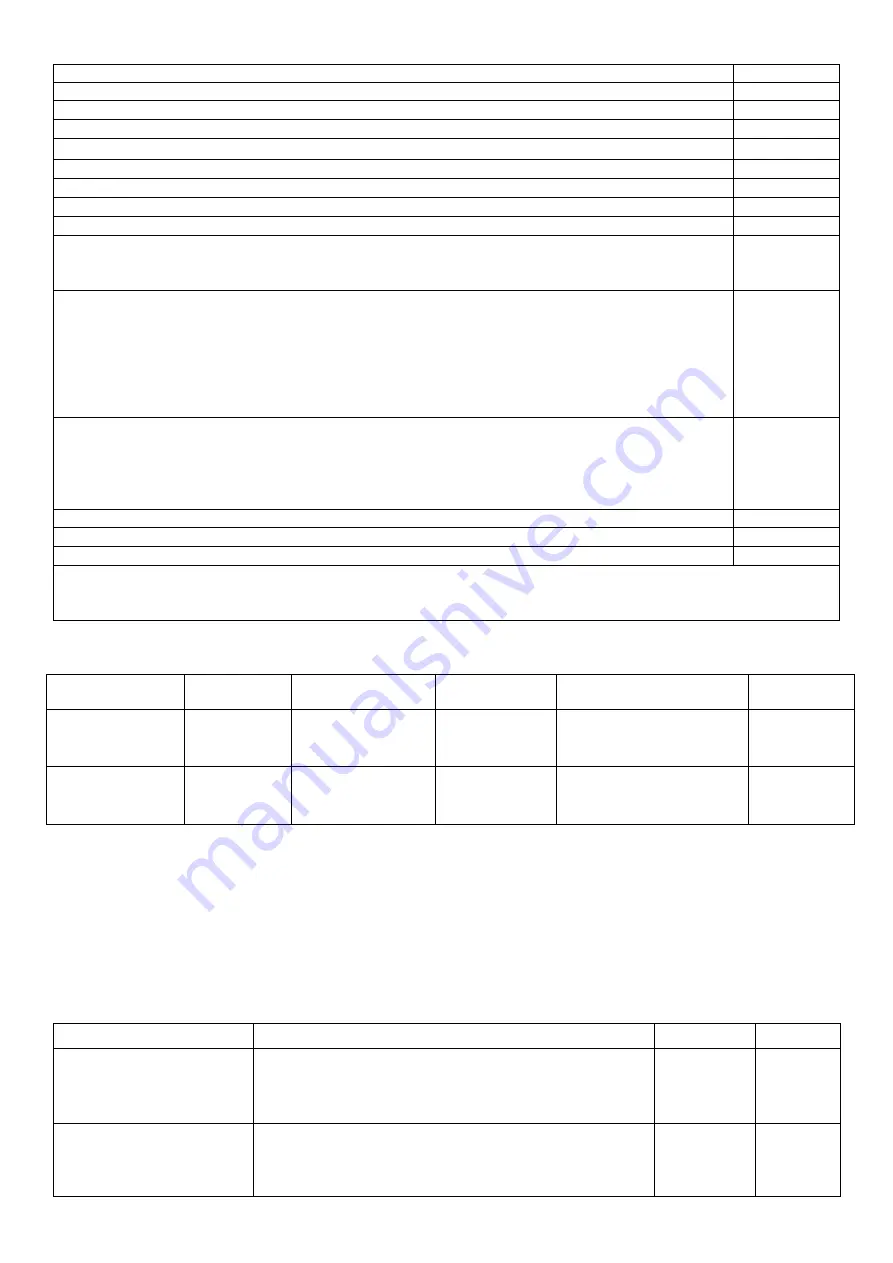

Table 3.2

–

Technical Specifications

Description

Value

Operating supply voltage, three-phase

415 V, 50 Hz

Mains frequency, Hz

48-62

Rated current of CT, A

5

(Phase/line) voltage hysteresis, V

10/17

Heat hysteresis, in % of accumulated heat in case of shutdown

33

Determination accuracy of trip threshold for current, not more, in % of rated value

2

Determination accuracy of trip threshold for voltage, not more, V

3

Determination accuracy of out-of-phase voltage, not more, V

3

Voltage when maintaining serviceability:

- phase voltage, when powered by one phase and zero wire is connected, not less, V

- line voltage, when powered by three phases, not more, V

180

450

Analog inputs:

- input to connect temperature transmitter (types: Pt100, Ni100, Ni120), pc.;

- input to connect temperature transmitter of PTC-1000 type, pc.;

- three analog inputs for standard CT with 5A output (T-0.66 type or similar), pc.;

- input to connect differential current transformer (zero sequence transformer) pc.;

- input to measure current of 0-20 mA, pc.;

- input to measure voltage of 0

–

10 V, pc..

1

1

3

1

1

1

Main outputs:

–

-load relay

–

two groups of changeover contacts to control the electric motor starter

–

8

A, 250 V at

cos φ=1;

–

functional relay

–

one group of changeover contacts - 16A, 250V at

cos φ=1 (

function of

the relay is set by the user).

Permit according to temperature of temperature transmitters,

°С

1

Power consumption (under load), VA, not more

5.0

Weight, not more, kg

0.34

Overall dimensions (Fig.1.1), H*B*L, mm 110*96*88,3

Position in space free

Housing material self-extinguishing plastic

Table 3.3

–

Characteristics of built-in relay output contacts

Relay

Max. current

at U~250V

Number of

actuations

х1000

Max. switching

power

Max. continuous

boosting AC / DC voltage

Max. current

at U

cont

=30V

Functional relay

Cos

= 0.4

Cos

= 1.0

5

А

16А

100

100

4000 V

А

440/300 V

5

А

Load relay

Cos

= 0.4

Cos

= 1.0

2

А

8

А

100

100

2000 V

А

460 V

3

А

3.2 MEASURED, CALCULATED, SPECIAL AND SERVICE PARAMETERS

Special and service parameters are intended only for transmission using MODBUS interface

(RS-485/RS-232). Special and service parameters are given in Table 3.4.

Measured and calculated parameters the values of which are displayed on LCD display, limits of their

measurements and accuracy are given in Table 3.5.

Parameter values can be transferred to PC connected to one of the UBZ interfaces (MODBUS, RS-232).

Parameter addresses are indicated in Table 3.5.

Table 3.4

–

Special and Service Parameters

Measurement functions

Range

Remarks

Address

Heat balance of the motor

Read-only parameter of

RS-232, RS-485 interface

The number 1100000 corresponds to 100% of

accumulated heat at which the motor is switched off

when the thermal overload protection is enabled (it

2.4.7)

Read-only

parameter

73,74

Index of the last fault in

the fault logbook

It varies from 0 to 49, increasing by one after recording

another fault in the fault logbook. When the quantity of

faults will reach 50, the count of faults will begin again

from scratch.

Read-only

parameter

75