21

5. Set the thermostat MODE the

ON

position.

6. Turn the gas valve ON. Push in and turn gas control

knob counter-clockwise to

ON

7. Replace the furnace door.

8. Turn on all electric power to the appliance.

9. Change the thermostat mode to

HEAT

and the

temperature selector to a desired temperature level.

The igniter should light in approximately 75 seconds.

If the appliance will not operate, see “How to Shut Off

Gas - Direct Ignition” on

and call your service

technician or gas supplier.

NOTE:

In the event of any flashback or explosion,

immediately shut off the furnace and call your service

technician.

How to Shut Off Gas - Direct Ignition Models

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance before

servicing unit.

3. Set the furnace On-Off Switch to

OFF

.

4. Turn gas control knob clockwise to

OFF

5. Replace the furnace door.

Verifying Input Rate

IMPORTANT NOTE:

The input rate must not exceed the rate shown on the

furnace rating plate. At altitudes above 2,000 feet, it

must not exceed that on the rating plate less 4% for

each 1,000 feet.

The input rate must be verified for each installation to

prevent over-firing of the furnace. To determine the exact

input rate, perform the following procedures:

1. Shut off all other gas fired appliances.

2. Start the furnace and run it for at least 3 minutes.

3. Measure the time (in seconds) required for the gas

meter to complete one revolution.

4. Convert the time per revolution to cubic feet of gas per

hour using

5. Multiply the gas flow rate in cubic ft per hr by the heating

value of the gas in Btu per cubic ft to obtain the input

rate in Btuh. See example.

Example:

• Time for 1 revolution of a gas meter with a 1 cubic ft

dial = 40 seconds.

• From

• Local heating value of the gas (obtained from gas

supplier) = 1,040 Btu per cubic ft.

• Input rate = 1,040 x 90 = 93,600 Btuh.

6. The manifold pressure must be verified for each

installation by a qualified installer, service agency or

the gas supplier. See

Verifying & Adjusting Temperature Rise

Confirm the temperature rise through the furnace is

within the limits specified on the furnace rating plate. Any

temperature rise outside the specified limits could result

in premature failure of the heat exchanger.

1. Place thermometers in the return and supply air stream

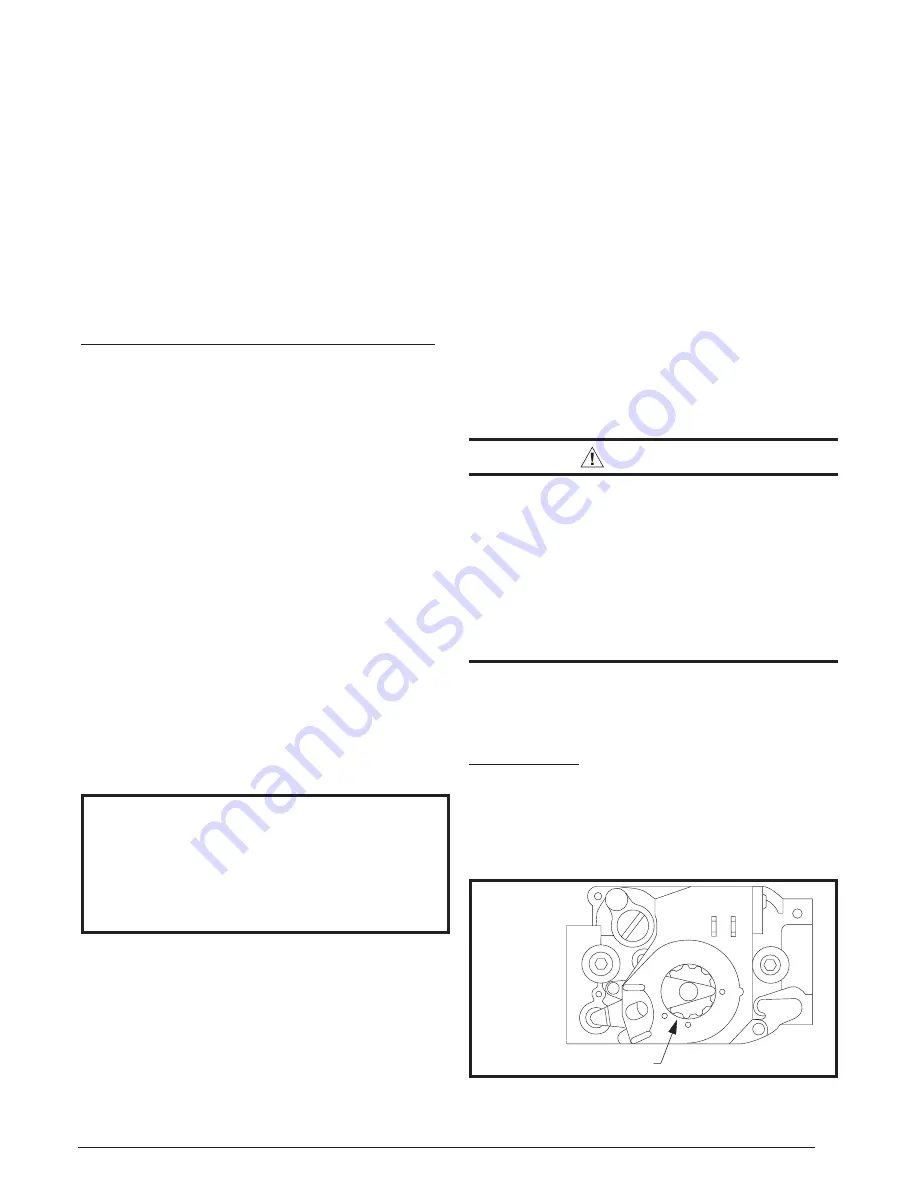

Figure 29. Direct Ignition Gas Valve - Honeywell

GAS CONTROL KNOB

as close to the furnace as possible. To avoid false

readings, the thermometer on the supply air side must be

shielded from direct radiation from the heat exchanger.

2. Adjust all registers and duct dampers to the desired

position and run the furnace for 10 to 15 minutes in

high fire before taking any temperature readings. The

temperature rise is the difference between the supply

and return air temperatures.

For typical duct systems, the temperature rise will fall

within the limits specified on the rating plate with the

blower speed at the factory recommended setting. If

the measured temperature rise is outside the specified

limits, it may be necessary to change the speed of the

blower.

NOTE:

Lowering the blower speed increases the

temperature rise and a higher blower speed will decrease

the temperature rise.

The furnace is equipped with a multi-tap ECM motor. For

alternate motor tap selections see

&

Burner Adjustments

CAUTION:

• Adjustment must be made only by a qualified

technician. Improper air adjustment may

cause unsafe operation, explosion and/or fire

asphyxiation.

• If the input to the furnace is too great because

of excessive gas pressure, wrong size nozzle or

orifice, high altitude, etc., the burner flame will

be sooty and can produce carbon monoxide,

which could result in unsafe operation,

explosion and/or fire or asphyxiation.

Burner settings are made at the factory. However, these

settings may change during shipping, handling, and

installation. The following items should be checked and

readjusted if necessary.

Gas Pressure

The gas pressure can be checked with a manometer at

the pressure tap located on the top of the gas valve.

Natural gas manifold pressure should be 3.5” W.C. and

L.P. gas manifold pressure should be 10” W.C. Replace

Summary of Contents for MG1 Series

Page 31: ...31...