REGULAR MAINTENANCE

PREVENTIVE MAINTENANCE

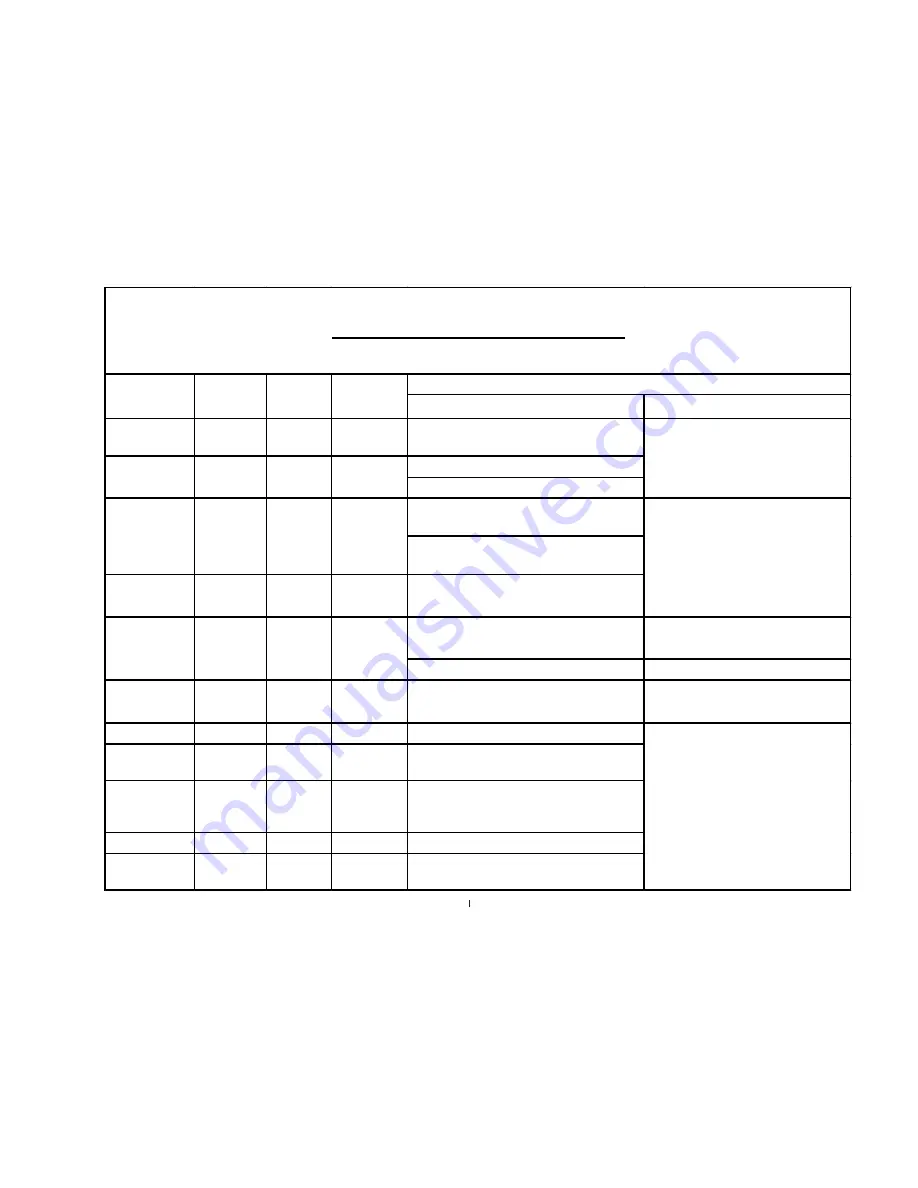

Hot Surface

Ignitor

X

- Check for continuity.

- Check that Flame Sensor is straight.

- Clean sensor with fine steel wool.

- Remove from the unit and clean with compressed

air from outside matting.

NOTE: It is recommended to replace the burner

gasket

each time a burner is removed.

Drain Lines

X

- Switch to drain and make sure water flows freely.

- Adjust blow down time when required. Check that

scale has not accumulated above 2".

- Drill out tank nipples when required to

ensure nipples are not blocked with scale.

- Clean tank when required.

- Clean tank.

Float Chamber

X

X

X

- Ensure floats move freely.

- Clean scale from float chamber and hose

connecting to hit.

Fill Lines

X

X

X

- Inspect for leaks.

Drain Lines

X

X

X

- Inspect for leaks at the drain pump, fill cup and

float chamber.

Gas Venting

X

X

X

- Inspect for leaks. Ensure terminal cap is clear and

any condensation produced flows to condensate

traps. Flue temp should be between 350-400ºF.

Direct Vent

X

X

- Inspect for leaks. Ensure intake terminal is clear.

H/L Stack Sensor

X

X

X

- Visual check that sensor is intact, wired and

attached to the exhaust.

- Replace hot surface ignitor and flame

sensor with replacement kit.

MANDATORY MAINTENANCE SCHEDULE

WHAT NEEDS TO BE DONE?

Flame Sensor

X

X

X

X

Tank

END OF

SEASON

MID

30 DAYS

after initial

start-up

PARTS

X

Gas Burner

-

2

9

-

Summary of Contents for GS 100

Page 76: ......