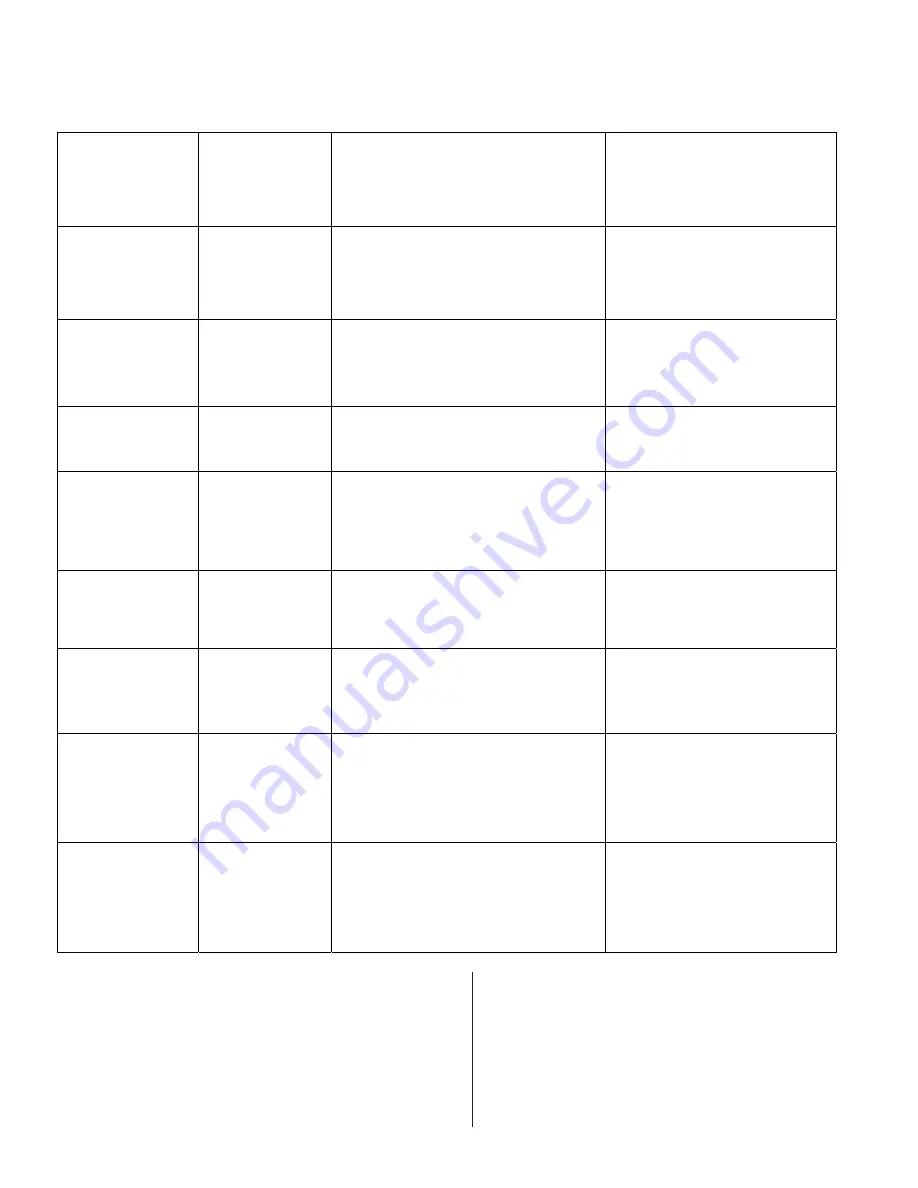

FAULT LIST

FAULT

GAS RE-IGNITION

BURNER X

GIF-X

Following an ignition module fault if the

modules gas valve activates this fault will be

generated.

-Ensure that the ignition module is not

miswired or that the module is not

faulty by swapping it with a known

good one. If the problem follows the

ignition module, replace the module

-Consult factory

FAULT

DRAIN NOT

WORKING

DRAIN IS BLOCKED

DBF

There are many time windows in the GS

software. If, during a drain cycle, the time

window for the water level to drop is exceeded,

this fault is generated

-Ensure that pump is being energized

-Check for blockage in all aspects of

the drain system

-Float board defective

-Consult factory

FAULT

FLOAT CHECK

FCF

Once every 24 hours (provided the unit is

powered and in an operating or standby

condition) the controller will test the water

level detection circuit. If the test fails this fault

is displayed

-Ensure the proper operation of the fill

valve and drain valve via the

diagnostics screen

-Float board is defective

-Consult factory

FAULT

ILLEGAL FLOAT

COMBINATION

WLF

If the controller detects two or more float level

readings, which are not expected (ex. Switch 1

and 3 ON or switch 1, 2, and 3 ON) this fault

will be recorded.

-Miswired float board

-Defective float board

-Consult factory

FAULT

FILL VAVLE ON

DETECTION

INCONSISTENT

FDF

The controller monitors the water level as it

fills and drains. It expects to see the levels

increase logically (1-2-3-4-5). If the water level

increases and jumps a step (1-2-4-5) this fault

will be generated. The same holds for water

level decreasing.

-Float board defective

-Contact agent for replacement float

board

FAULT

KEEP WARM TIME

OUT

TOO LONG TO

HEAT

KWF

During a keep warn cycle, if the tank

temperature sensor does not open within a

certain time window, this fault is generated.

-Ensure that the tank temperature

sensor is connected

-Defective tank temperature switch

-Contact agent for replacement switch.

FAULT

STACK OVER

TEMP.

SWITCH TRIPPED

OTF

If input TB5, # 4 on the logic board goes low

(no 24 Vac detected) this fault will be

generated. This could indicate either the tank

over temperature switch has opened or the

stack over temperature switch has opened.

-Do not operate and consult the factory

FAULT

MAINTENANCE

TIME

HAS ELAPSED

HMF

In the user menu the user sets the maintenance

time. Once this time expires a warning is

displayed. 72 hours later the warning changes

to this fault. The maintenance time is measured

in weighted operational hours.

With switch 5, #4 deactivated, this fault is

enabled

-Perform tank cleaning and all other

maintenance requirements outlined in

the manual.

FAULT

WATER FILL FAIL

FTF

Fill time-out fault during fill process. The GS

software monitors the changes in water level

during filling sequence. If ware level changes

do not occur within an expected time interval,

this fault will be generated.

-Verify water supply is open

-Verify adequate water supply to unit

(30-80psi, 10L/min, minimum ½” dia.

Line size)

-Verify wire harness and connection

between float chamber and I/O board

(TB)

- 61 -

Summary of Contents for GS 100

Page 76: ......