·

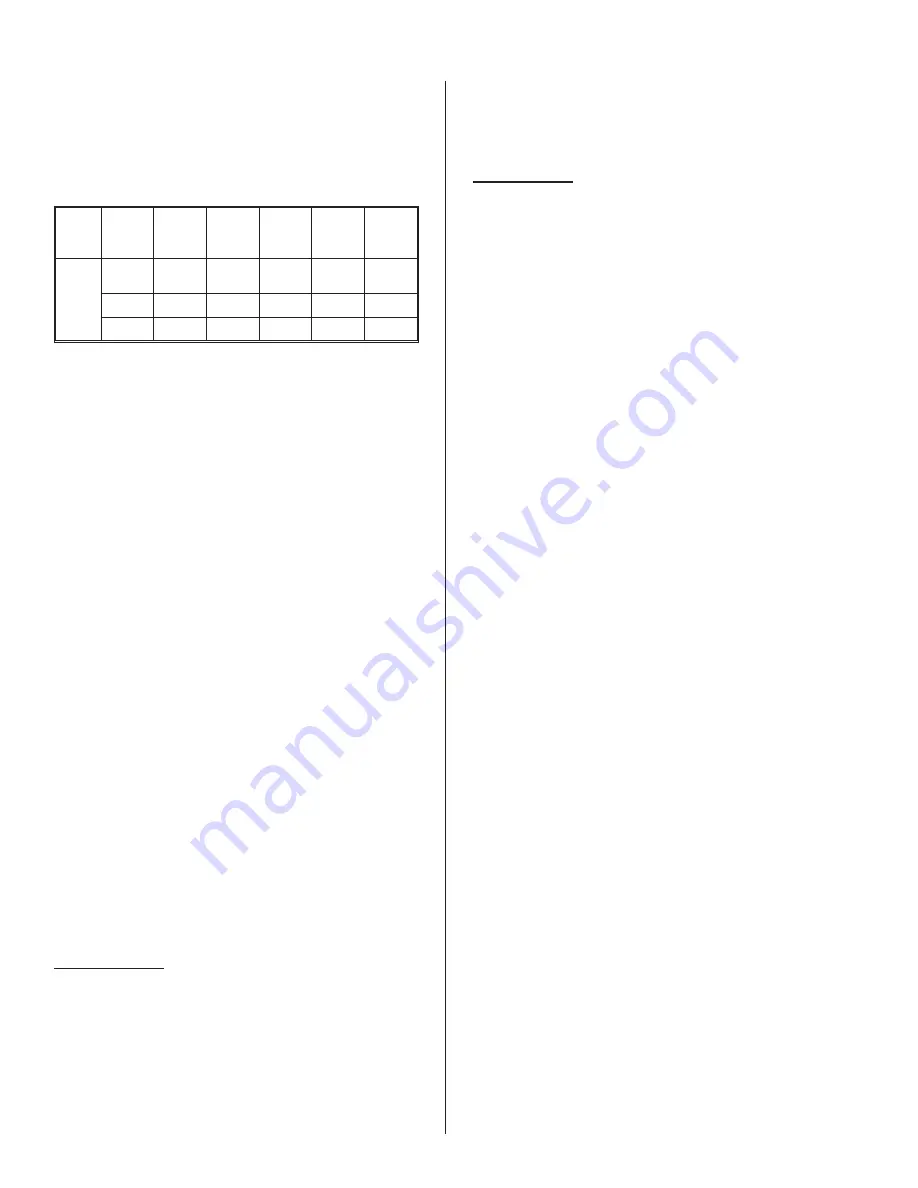

Conductivity: Measured in micromhos. Follow

the directions for the conductivity pen found

inside the box. Multiply the digital reading by 1.5.

The recommended operating range for

conductivity is 0 - 1500 micromhos. Consult the

factory is you measure outside these parameters.

Tech-

nology

Water

Type

Water

Cond.

Range

Hard-

ness

Range

Silica

Range

Alkalin.

Range

Chlor.

Range

Gas-

Fired

Microm

hos

GPG

PPM

pH

PPM

Potable 0-1500 0-12

0-14

6.5-7.5 0-25

Treated 0-100

0-1

0-1

7-7.5

0-25

·

NORTEC recommends performing a semi-annual

water analysis to ensure optimal performance.

·

The humidifier is intended to operate on cold

potable tap water.

·

DO NOT use a hot water source to supply the

humidifier. Minerals will adhere more easily to

surfaces and the fill valve's small flow regulating

orifice could become plugged.

·

Consider using a water softener. Longer

operating times between tank cleaning will be

reached on softened water.

·

Reverse osmosis (RO) water can provide very

long times before cleaning is required since it is

cleaner than softened water. Deionized (DI)

water may be used with all models. Consult your

NORTEC representative for quote on a water

treatment system.

SAFETY INSTRUCTIONS

Refer to front cover and page 1 of this guide.

FAULT CONDITIONS

This appliance is equipped with a self diagnostic

ignition module which identifies a fault code when it

occurs. Refer to the fault & warning list on pg 60.

GSTC MODELS

Faults are indicated with a fault message on the

display of GSTC models. Recovery from lockout

requires resetting of the humidifier. This can be

achieved by momentarily shutting off the power switch

then turning it back on, or by pressing the reset button

on the logic control board mounted inside the electrical

cabinet.

A history of all faults is stored in memory of

the software and can be viewed through the service

level on the display. Refer to the keypad display menu

structure at the end of the manual.

GSP MODELS

Faults are indicated on GSP models with a fault

code on the small display screen attached to the logic

control board. The display can be viewed by removing

the front electrical door. Check the display for the fault

code before shutting off power to the unit. Resetting

the humidifier clears the fault. This can be achieved

by shutting off the power switch, then turning it back

on, or by pressing the reset button on the logic control

board. A list of all fault codes and the type of fault they

represent is located near the back of the manual.

MAINTENANCE

To ensure proper performance and long operating

life of the GS humidifier, it is recommended that the

appliance and installation be inspected at least once a

year by a qualified service person. A proper

maintenance schedule should be followed. Since the

amount and type of maintenance required is generally

as a result of how much the humidifier operates, all GS

humidifiers monitor the amount of steam produced

over time and will indicate when service is required.

All units come factory set with a service interval of 500

hours. This service interval can be adjusted through

software (GSTC models) or by dip switch settings

(GSP models) on the logic control board.

All maintenance work must be performed by

experienced and trained personnel.

Periodic cleaning of the screens in the vent

terminal (where applicable) is recommended.

NOTE Use only NORTEC original parts to

replace damaged or defective components. Failure to

do so may cause improper operation of the humidifier

and will void warranty.

DRAINING THE TANK

·

During extended periods of inactivity such as off

season or periods of very low demand, it is

advisable to drain the water from the tank. On all

models this is accomplished by switching the unit

to “Drain”.

·

Do not remove the front clean out port on the

tank until the unit has completely drained. On GS

300-600 units do not remove the top clean out

ports on the tank unless the water has cooled or

the unit has completely drained.

- 28 -

Summary of Contents for GS 100

Page 76: ......