STEAM LINES

·

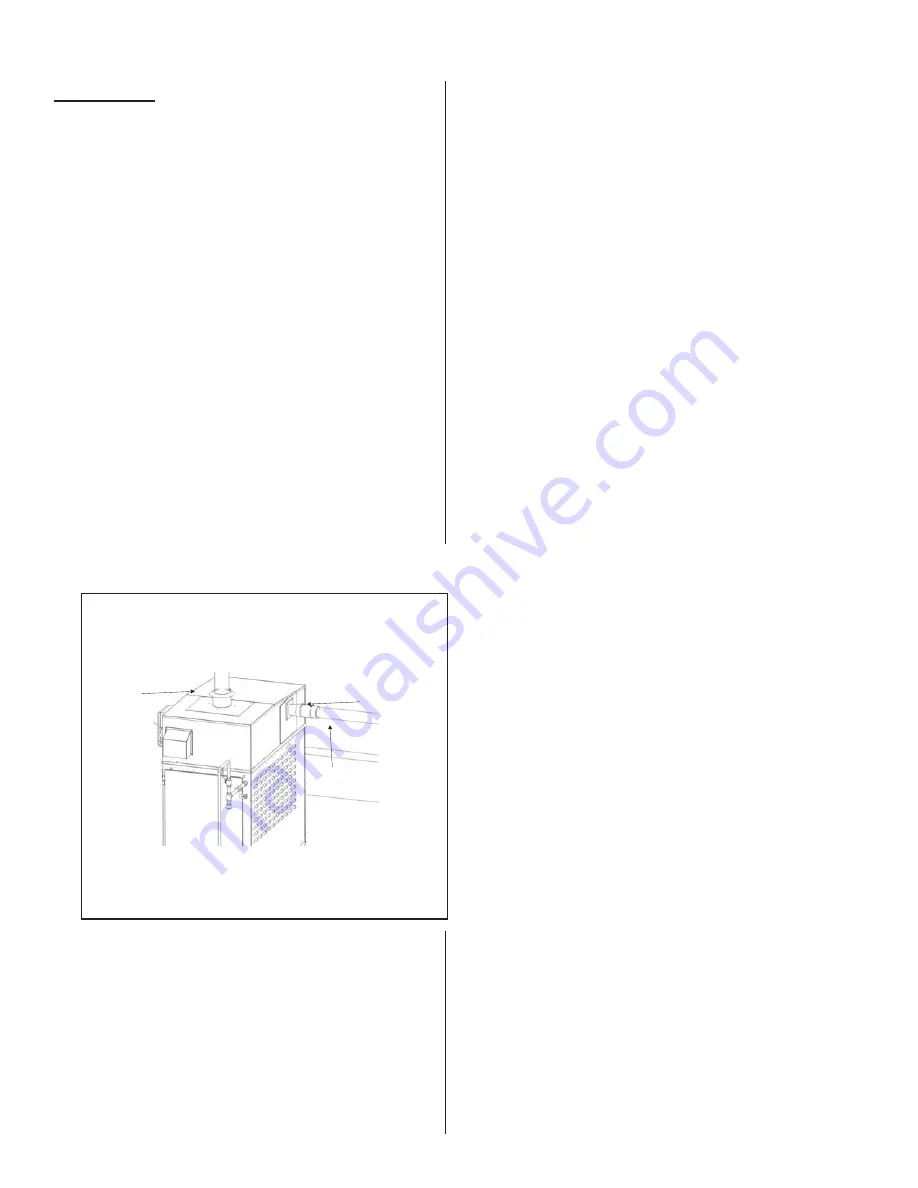

The steam outlet connection is located at the

back of the GS Outdoor unit. Steam hose(s) and

clamps are supplied with the unit and are

intended to provide a flexible coupling outside of

the unit to the building steam lines. See Figure

#23.

·

GS Outdoor models can develop steam

pressures up to 12”w.c. to overcome duct and

steam line pressures. Pressures above 12”w.c.

will cause steam to exit through the drain line.

·

Steam lines can be routed to an air handler on

the roof or pipe chased (external to the unit)

through the rooftop to enter the building.

·

All steam lines must be insulated to reduce

losses.

·

For steam line installation guidelines, consult the

distribution system installation manual (Steam

Distributor Installation Manual Form #XX-231 and

SAM-e Short Absorption Manifold Form

#XX-249).

PRINCIPLES OF OPERATION

Combustion

The combustion system is based on a fully

modulating forced draft combustion air blower(s), a

negative pressure regulated gas valve, and a 100%

premix burner. On a call for humidity, the combustion

air blower(s) starts and creates a negative pressure(s)

across an orifice located at the air inlet. The blower is

energized to purge the system, then the hot surface

ignitor is activated. During this time the electronic

ignition module does a diagnostic check of safety

systems including the air proving switch which senses

the negative pressure at the air inlet orifice. After the

function of the safety systems has been verified, the

gas valve(s) will open and the gas/air mixture is ignited

by the hot surface ignitor. If a flame is sensed by the

flame sensor, the gas valve(s) remains open and

combustion continues. If a flame is not sensed, the

above sequence is repeated to a maximum of three

times after which the ignition module will lock out. The

gas valve(s) maintains a constant ratio air to gas

independent of blower speed or external conditions.

This air and fuel is thoroughly mixed in the blower(s)

and then forced through the burner ports where

ignition occurs.

Hot products of combustion are forced through a

baffle inside the heat exchanger and then vented

outside. The heat exchanger has a large flat surface

to minimize scale build-up and promote scale

shedding to the bottom of the tank. This self-cleaning

action helps to maintain the efficiency of the heat

exchanger while the smooth surfaces allow for easy

cleaning when necessary.

The GS 100 has a single removable combustion

chamber/heat exchanger. The combustion system is

duplicated on larger units with multiple chambers

inside a common tank.

WATER MANAGEMENT

The GS Series of humidifiers is equipped with a

unique float chamber water level monitoring device.

Two magnetic floats (one is a backup) measure 5

different water levels in the humidifier for proper

operation. The float chamber and board are located

away from the boiling action to increase reading

accuracy and reduce mineral build-up since it is not in

the boiling water. The float chamber is connected to

the tank under the water level and above the water

level to ensure equalization of pressure between the

tank and float chamber. In addition, cooling water is

introduced in the float chamber to reduce scale

build-up. The unit also includes an internal 1” air gap

and a vacuum breaker to prevent siphoning effect.

- 22 -

Cuff hose and

clamps provided

Steam line

(Insulation

recommended)

BH Venting

Supplied

Figure #23

Steam Connection

Summary of Contents for GS 100

Page 76: ......