28

www.hysecurity.com

16 - TROUBLESHOOTING (CONT.)

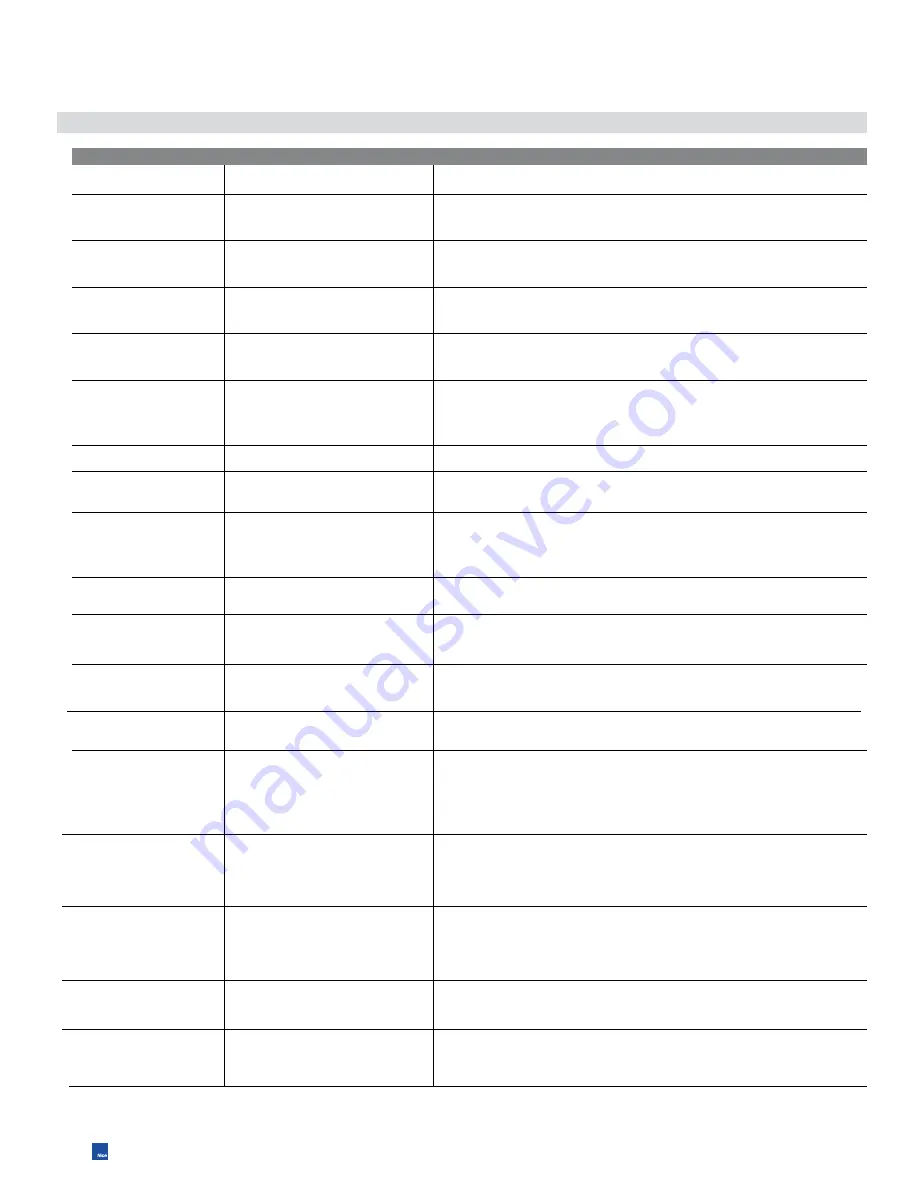

Table 4: 1050 Board Display Read Out and Troubleshooting

DISPLAY

REASON

POSSIBLE SOLUTION

Dynamic M1

Dynamic M2

Static M1

Static M2

Input UL/Edge

Photo Test FAIL!

Device Error

Gate Opened

BlueBus or

Input - Activated

Hard Shut Down

Overload

Slide Requires -

Min 2 Sensors

1 Open & 1 Cls -

Sensor Required

Min. 1 Sensor -

For Swing Gate!

BlueBus Error!

Scanning BluBus -

Prs Disp to Cncl

Input STOP!

Actuated connected to Motor

1 has a brief current spike and

tripped Type A sensor.

Actuated connected to Motor

2 has a brief current spike and

tripped Type A sensor.

Actuated connected to Motor 1

has an extended current spike

and tripped Type A sensor.

Actuated connected to Motor 2

has an extended current spike

and tripped Type A sensor.

UL/Edge input is tripped while gate

is running. Appears is IN1 or IN2

input is tripped if configured as a

pulsed, external sensor input.

BlueBus monitored sensor check

fails.

Position sensor is not being correctly

detected by the board or if there is

an active input on the board prevent-

ing the learn process.

Appears during Learn Mode if Open

Limit is active.

Appears when active BlueBus or

other external entrapment sensor

input is preventing gate motion.

Appears when Dynamic and/or

Static sensors have two sonsecutive

trips.

Appears when Motor 1 or Motor 2

over-current.

Appears when there are not at least

two external entrapment sensors

programmed and installed on a Slide

Gate:

1. Open direction

2. Close direction.

Appears when Slide Gate operator

does not at have at least one exter-

nal entrapment sensor programmed

and installed in each direction.

Appears when Swing gate operator

does not have at least one entrap-

ment sensor programmed and

installed for both open and close

direction for travel.

Appears when previously learned

numbers and type of BlueBus sen-

sors change.

Appears when initial BlueBus learn

procedure is in process.

STOP input is not connect to GND.

Check for obstruction in gate path or degraded gate hardware.

Check for obstruction in gate path or degraded gate hardware.

Check for obstruction in gate path or degraded gate hardware.

Check for obstruction in gate path or degraded gate hardware.

Ensure photo eyes are aligned, edges are not tripped, and all inputs are pro-

grammed correctly.

Verify photo eye is connected, aligned, and internal jumpers are set correctly.

Ensure Motor 1 and Motor 2 position sensors are connected correctly for the type

of actuator being used. Also make sure there are no active inputs.

Change gate to mid-travel and restart the learn process.

Ensure all sensors are connected correctly and properly aligned.

Ensure all inputs are programmed correctly.

Press the Reset/Hard Shut Down button to clear the trip and reenable gate oper-

ation.

Ensure motors are connected properly and there is no obstruction to gate move-

ment.

Ensure all sensors are connected correctly and functional.

Does not appear on Swing gates.

Ensure all sensors are connected correctly and functional.

Does not appear on Swing gates.

Install minimum number of sensors.

Does not appear on Slide Gates

Correct wiring/number of sensors and redo the learn procedure for the operator.

Pressing the Display button will postpone the scan and remain in Learn Mode.

Pressing and holding the open or close buttons will move the gate in the desired

direction.

Ensure jumper wire is being used and check external stop button wiring.

Summary of Contents for TITAN12L

Page 2: ......

Page 33: ...www hysecurity com 33...

Page 34: ...34 www hysecurity com...

Page 35: ...www hysecurity com 35...