27

safety device.

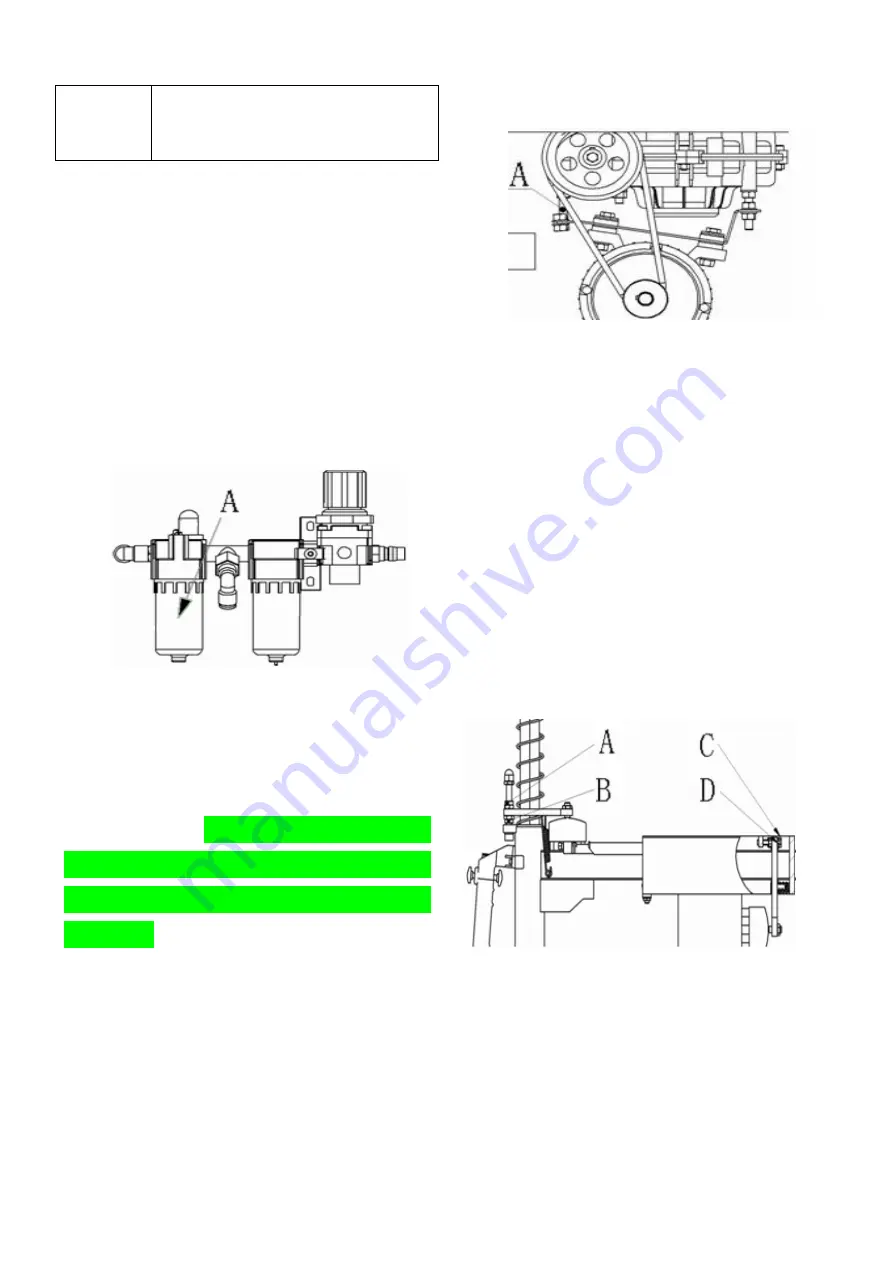

8.2Maintenance

Every week, use the kerosene to clean the turntable to

prevent the come out of the dust. Lubricate the clamping jaw

guide rail. Check the oil level of the grease container at least

every 30days. If necessary, release the screw and fill in the

oil tank oil tank

(

Fig8-1

)

,

Only use the lubrication oil(ISO

VG viscosity, ISOHG grade) to lubricate the compressed air

route.

Fig 8-1

Check whether one drop of oil will drop after 3-4 times of

stepping down the pedal

(

Fig2-1 I

)

. If not, use the top end

screw to adjust

(

Fig8-1

)

.

First time of using for 20days, tighten the fix screw on the

turntable chute

(

Fig23

)

Note

:

The system pressure has been

adjusted before the machine is delivered out of the

factory. It is prohibited to adjust air regulator without

authorization.

If it is without power, check whether the driving belt is

loose.

Via special adjust screw on the motor rack

(

Fig8-2

)

to detach

the driving belt.

Fig 8-2

8.3 Clearance adjustment between the tool head and

rim

8.3.1。Vertical clearance: Adjust hex shaft lock

plate: Switch off the air source and detach the

protective cover of the vertical hex shaft. If the

clearance is too big, you can downward adjust the

upper and bottom nut at the front end of the hex lock

plate. If small, you can upward adjust the upper and

bottom nut at the front end of the hex lock plate.

(Fig8-3 A、B)After connect the air source, observe

the shift condition

Fig8-3

8.3.2Use spanner to loose the lock nut on the M6 screw

at the two end. Adjust the M6 screw

(

Fig

8-3 C

),

meanwhile use your hand to push the quadric shaft

until it runs smooth and then lock the nut.

Summary of Contents for TC-1300

Page 1: ...3456789 C61CN...

Page 36: ...35...