9

Fig 4-8

4.2.14 Air test:

After connect the air source, press down the lock

valve press button Fig2-2 to lock the horizontal

arm. Step down column tilting pedal (Fig2-11)

and the column will tilt back by about 25 º. The

tilting speed of the column has been set to be about

2 seconds before the machine is delivered out of

the factory. After long us, the speed will become

too slow or too fast. You can use the speed adjust

valve at the two head of the push-out cylinder.

Release the nut and clockwise adjust the speed of

the screw to be slow and counterclockwise adjust

the speed of the screw to be fast. After adjustment,

tighten the nut.

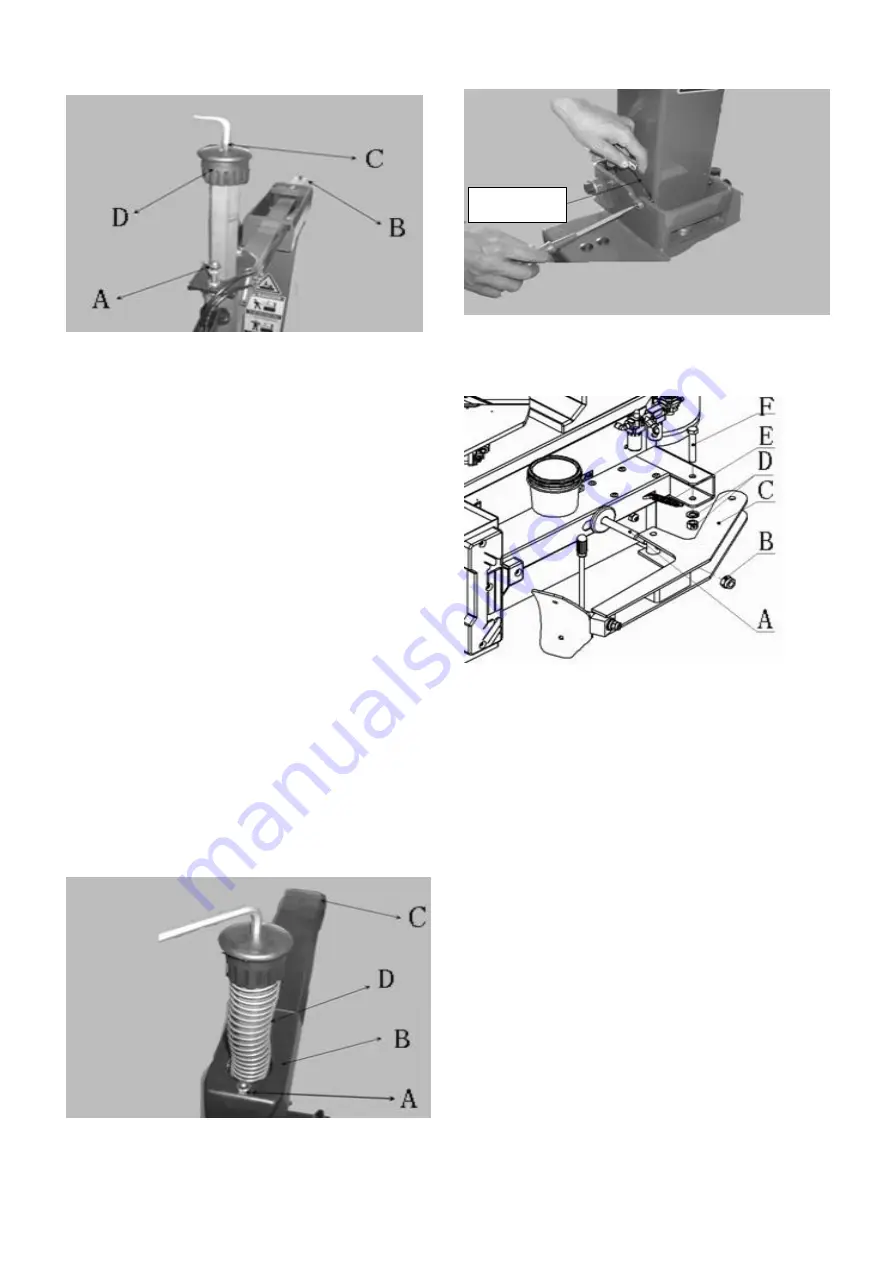

Fig 4-9

Fig 4-10

4.2.15 Install the bead breaker arm

Fig 4-11

4.2.16 Unscrew the stop nut (Fig4-11 B)from the

top end of bead breaker piston rod and unscrew the

bolt connect on the machine cabinet(4-11 F)

(4-11

D). As per the instruction of Fig4-11, insert the

bead breaker blade (4-11 C)through the cylinder

piston rod(4-11 A). Hang one end of the bead breaker

arm spring(4-11 E)on the machine cabinet and then

insert the bolt(4-11 F) through the machine cabinet

and blade and use the nut and flat washer(4-11 D)

and bolt (4-11 F)to connect and fix. Tighten the

stop nut(4-11 B)and bead breaker cylinder piston.

Hang the other end of the bead breaker arm spring

(4-11 E)Fig 4-11 on the spring pin shaft(4-12 A)

L=0.3mm

Summary of Contents for TC-1300

Page 1: ...3456789 C61CN...

Page 36: ...35...