19

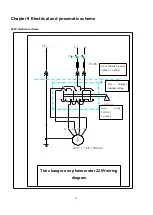

Fig 7-1

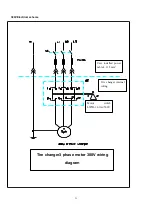

Fig 7-2

7.1.1 There is the installation hole prepared at the

back of the base plate of the machine cabinet of each

machine that can handle the tire more than 20″.

Before installation, detach the side panel and then

the T rubber plug.

7.1.2 Open the package box of PL330 helper and then

check whether the spare parts is are intact as per

the packing list Fig 7-2. And then take out the base

frame assembly(Fig7-1)and detach the screw and

washer on it.

7.1.3 Push the base plate of the base assembly into

the machine cabinet from left back, making the

thread hole align to the reinforcement hole. Use

the bolt and washer to fix(Fig7-2).

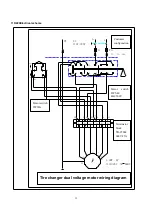

7.1.4 Place the main frame support(Fig7-3 A)

on the base assembly

Fig 7-3

. Align and use the screw

unscrewed before Fig(7-3) to fix. Remind not too

tight.

Fig 7-3

Fig 7-4

7.1.5 Use the fix bracket(Fig7-4 A)to connect the

main frame support with the machine cabinet and

insert the screw to fix.

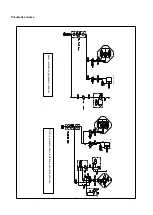

7.1.6 Use the Y Tee to connect the air source

(Fig7-5 A)and the other end is connected with the

helper pressure valve inlet.

7.1.7 Connect the air route. Insert the tire press

roller connect rod(Fig 7-6 A)into the rotating

arm rotating shaft hole(Fig7-6 B). Operate the

handle direction changing valve to make the tip of

the tire press conic roller align with turntable

Summary of Contents for TC-1300

Page 1: ...3456789 C61CN...

Page 36: ...35...