2.4

TRACE

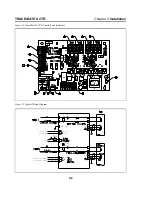

MATE II-CTR

Chapter 2 Installation

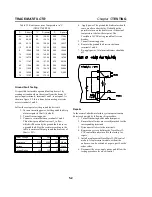

You must install the RTD sensor on the pipe surface or

thermal well before the pipe insulation to ensure proper

thermal contact. The RTD position should be 180° from

the electric heat trace cable which is the coldest spot of

the pipe. The RTD sensor may be secured to the pipe by

fiber-glass tape. If additional wiring is required for the

RTD, shielded 3-lead wire sized 18 or 20AWG must be

used for the RTD sensor to minimize the effects of noise

pickup. A typical RTD installation is shown in Figure 2.4.

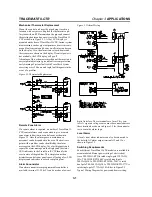

Alarm Wiring

TraceMate II-CTR has two passive alarm contacts. Both

of them are configured as normally closed contacts. Also,

TraceMate II-CTR has a Form C alarm dry contact. Refer

to Figure 2.2 for alarm output terminals.

The AC triac alarm output is rated 12-277Vac, 0.5A. The

DC alarm output is an opto-isolated transition output

rated 30Vdc/100mA, 500mW max. The Form C dry

alarm contact is rated 0.5A 277Vac/0.1A 30Vdc max.

These alarm outputs are designed to interface to

annunciator, panels, PLC or DCS.

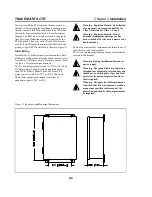

Figure 2.5 Enclosure and Mounting Dimensions

Warning - Explosion Hazard - Substitution

of components may impair suitability for

Class 1, Division 2 or Class 1, Zone 2.

Warning - Explosion Hazard - Do not

disconnect equipment unless power has

been switched off or the area is known to be

non-hazardous.

There are no consumable components contained in any of

the models covered in this manual.

There is no cleaning requirements for any of the modules

covered in this manual.

Warning - During installation, disconnect

power supply.

Warning - The ground fault trip function is

intended for equipment protection only and

should not be used in place of ground fault

protection for personnel protection where

this is required.

Warning - The operator of this instrument

is advised that if the instrument is used in a

manner not specified in this manual, the

protection provided by the equipement may

be impaired.