TRACE

MATE II-CTR

Chapter 5 TESTING

5.1

Troubleshooting/System Integrity

A major concern in heat tracing is knowing that the

control and heater cable are functioning normally. On

systems that sit idle for long periods, such as freeze

protection, faults usually show up when the system is

needed most. Users often perform an annual check on

mechanical thermostats to ensure that problems have not

developed. This is a tedious task because the controls are

often high off the ground in inaccessible areas.

Since the TraceMate II-CTR control uses RTDs, it can be

mounted in a convenient ground level location near other

controls for easy access. Indicator lights for HEATER ON

and POWER indicate the system status. If an RTD sensor

or wiring goes open/short circuit, an RTD Fail on HTRx

alarm message appears on the LCD display and the RTD

FAIL LED comes on indicating a fault. For this condition

the actual temperature output indicates a value out of the

temperature measurement range, i.e. [-50°C-500°C] or

[-58°F-932°F].

The control can be forced on or off easily by changing the

heater setpoint switches to be above or below the actual

process temperature, noting the HTR ON LED and heater

current with a clamp-on ammeter.

Calibration

Although the TraceMate II-CTR control is constructed

with precision components and should give long service

without any recalibration necessary, users however may

wish to perform periodic calibration checks. When the

TraceMate II-CTR control is first installed, or for periodic

maintenance checks, system operation can be verified by

adjusting the heater setpoint 2°C above and below a

known temperature on the RTD input to see if the heater

turns on and off. For example, if the RTD input

temperature is 25°C, setting the heater setpoint to 27°C

will force the heater on and conversely a 23°C setpoint

will force the heater off.

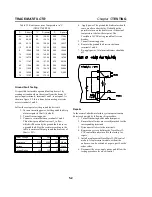

By substituting a known resistor value for the RTD sensor

and looking up the equivalent temperature in tables 5.1

and 5.2, the calibration accuracy of the control can be

verified. This can be done in the field without removing

the control using a resistance simulator box and a quality

digital multimeter.

Disconnect the incoming RTD wires and connect a

resistance box. Simulate an RTD temperature using the

variable resistor or decade box and set the heater setpoint

2°C above the simulated temperature. The HTR ON LED

should turn on. Setting the heater setpoint 2°C below the

simulated temperature, the LED should turn off.

Table 5.1 Resistance versus Temperature in °F

(DIN 43760 RTD)

°F

R (ohms)

°F

R (ohms)

°F

R (ohms)

-40

84.27

160

127.50

360

169.29

-30

86.47

170

129.62

370

171.34

-20

88.66

180

131.74

380

173.39

-10

90.85

190

133.86

390

175.43

0

93.03

200

135.97

400

177.48

10

95.22

210

138.08

410

179.51

20

97.39

220

140.18

420

181.55

30

99.57

230

142.29

430

183.58

40

101.74

240

144.38

440

185.61

50

103.90

250

146.48

450

187.63

60

106.06

260

148.57

460

189.65

70

108.22

270

150.66

470

191.67

80

110.38

280

152.74

480

193.68

90

112.53

290

154.82

490

195.69

100

114.68

300

156.90

500

197.69

110

116.83

310

158.97

120

118.97

320

161.04

130

121.10

330

163.11

140

123.24

340

165.17

150

125.37

350

167.23