TRACE

MATE II-CTR

Chapter 4 Operation

4.2

High Temperature Alarm Setpoint: If the jumper is at HT

position, the Setpoint Number is interpreted as the high

temperature alarm setpoint in °C or °F for the selected

heater. The factory default value is 100°C.

Ground Fault Trip Alarm Setpoint: If the jumper at GF

position, the Setpoint Number is interpreted as the ground

fault trip alarm setpoint in mA for the selected heater. The

factory default value is 30 mA.

Current Fail Alarm Setpoint: If the jumper is at AMP

position, the Setpoint Number divided by 10 is inter-

preted as the current fail alarm setpoint in A for the

selected heater. The factory default value is 0.3 A.

NONE: If the jumper is at NONE position, the Setpoint

Number has no meaning to any heater.

Once the jumper is at NONE position, all the adjusted

setpoints will be saved in EEPROM which means that

their values will not be changed even after power off.

It would be very helpful to use the setpoint messages on

the LCD display to verify if the desired setpoint has been

properly set or not.

1. For heater x’s setpoint, the message is “SPx = ---°C”,

or “SPx = ---°F”. Where, x refers to the heater number. It

could be either 1 or 2. This message would be the sole

message on the display if JP1 is at SP position.

2. For heater x’s low temperature alarm setpoint, the

message is “LT SPx = ---°C”, or “LT SPx = ---°F”. This

message would be the sole message on the display if JP1

is at LT position.

3. For heater x’s high temperature alarm setpoint, the

message is “HT SPx = ---°C”, or “HT SPx = ---°F”. This

message would be the sole message on the display if JP1

is at HT position.

4. For heater x’s current fail alarm setpoint, the message

is “AMP SPx = --- A”. This message would be the sole

message on the display if JP1 is at AMP position.

5. For heater x’s ground fault trip alarm setpoint, the

message is “GF SPx = --- mA”. This message would be

the sole message on the display if JP1 is at GF position.

6. If JP1 is at NONE position, the messages such as

system measurements, setpoint values, heater on/off and

alarm status will be continously cycled through on the

LCD display.

to the factory for service.

Heater On Indicator: Whenever a heater is on, the green

HTR ON indicator LED will be on if the heater is

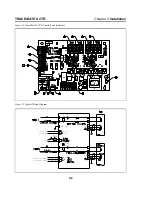

selected by S12, refer to Figure 2.1. This is useful for

checking correct operation of the control. If the ground

fault alarm light or RTD fail alarm light is on, the heater

will not switch on even if the actual temperature is below

the setpoint.

Alarm Reset

The low/high temperature and RTD fail alarms reset as

soon as the condition disappears. The ground fault trip

and current fail alarm are latched alarms. A latched alarm

will remain even if the alarm condition disappears. To

reset the latched alarms, remove heater 1’s incoming

power for a few seconds by opening and reclosing the

circuit breaker. Provided the alarm conditions are no

longer present, the alarms should all be reset when power

is re-applied. It is also possible to use S11 to reset the

latched alarms on the selected heater. To do that, first use

S12 to select the heater, and then momentarily switch S11

towards its ON position ( refer to Figure 2.1 ).

Heater Setpoint and Alarm Setpoints

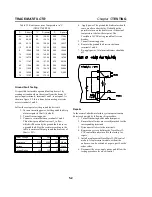

As stated in chapter 2, five setpoints can be adjusted by

properly setting up S1-9, S10, S12 and JP1 ( refer to

Figure 2.1 ). S1-9 consisits of 9 switches. They are S1,

S2, S3, S4, S5, S6, S7, S8 and S9. These 9 switches

generate a Setpoint Number in a range of 0-511. The

exact value of this Setpoint Number equals the sum of the

contributions from each switch. If a switch is in ON

position, its contribution to the Setpoint Number equals

its labelled value on the board. Otherwise, its contribution

is zero. For example, if all 9 switches are all in ON

position, Setpoint Number = 1 + 2 + 4 + 8 + 16 + 32 + 64

+ 128 + 256 = 511. If only switches S3 and S5 are in ON

position, Setpoint Number = 0 + 0 + 4 + 0 + 16 + 0 + 0 +

0 + 0 = 20.

Whether the Setpoint Number is for heater 1 or heater 2

depends on the position of switch S12.

Depending on the jumper position of JP1, the Setpoint

Number generated by S1-9 can be interpreted as either

heater setpoint, or low temperature alarm setpoint, or high

temperature alarm setpoint, or ground fault trip alarm

setpoint, or current fail alarm setpoint.

Heater Setpoint: If the jumper is at SP position, the

Setpoint Number is interpreted as the heater setpoint for

the selected heater. Whether the setpoint is in °C or °F

depends on the position of S10 ( refer to Figure 2.1 ). The

factory default value is 20°C.

Low Temperature Alarm Setpoint: If the jumper is at LT

position, the Setpoint Number is interpreted as the low

temperature alarm setpoint in °C or °F for the selected

heater. The factory default value is 5°C.