- 51 -

NL450C

www.NewLeader.com

(800) 363-1771

307306-AA-D

Header

Figure 4 - Fin

Figure 5 - Spinner De

fl

ector

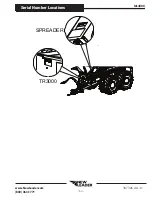

Figure 6 - Material Divider

Spinner Fins

Visually inspect spinner

fi

ns (Figure 4) daily for

build-up of material and wear. Spinner discs

and

fi

ns must be kept clean and polished.

Even a small build-up of material on a spinner

can signi

fi

cantly affect the spread pattern.

Rough, bent or worn

fi

ns will produce bad

spread patterns. Replace worn

fi

ns or discs as

needed. See Fin Kit Installation Instructions for

replacement part numbers and instructions.

Spinner De

fl

ectors

Visually inspect spinner de

fl

ectors (Figure 5)

daily for build-up of material and damage.

Clean as needed. Even a small build-up of

material on a spinner de

fl

ector can affect the

spread pattern. If damaged, bent or otherwise,

replace. See Parts List in this manual for

replacement part numbers.

Material & Hillside Flow Dividers

Visually inspect material divider (Figure 6) and

hillside

fl

ow dividers (as equipped) daily for

build-up of material and wear. Any build-up

of material on divider components can affect

performance. Clean as needed. Replace worn

or damaged parts as necessary. See Parts List

in this manual for replacement part numbers.

Lubrication & Maintenance