- 57 -

NL4258/4330G4 EDGE

www.NewLeader.com

(800) 363-1771

312521-AA-C

Lubrication & Maintenance

NOTICE!

The conveyor will move away from the bottom panel if material accumulates under the conveyor or

on the sprockets� The more material that accumulates, the closer the chain will come to the chain

shields� If the conveyor should catch a chain shield, it could permanently damage the conveyor, the

chain shields or the unit� Do not remove material while conveyor or spinner is running!

Lubrication

Make sure unit is clean and completely dry�

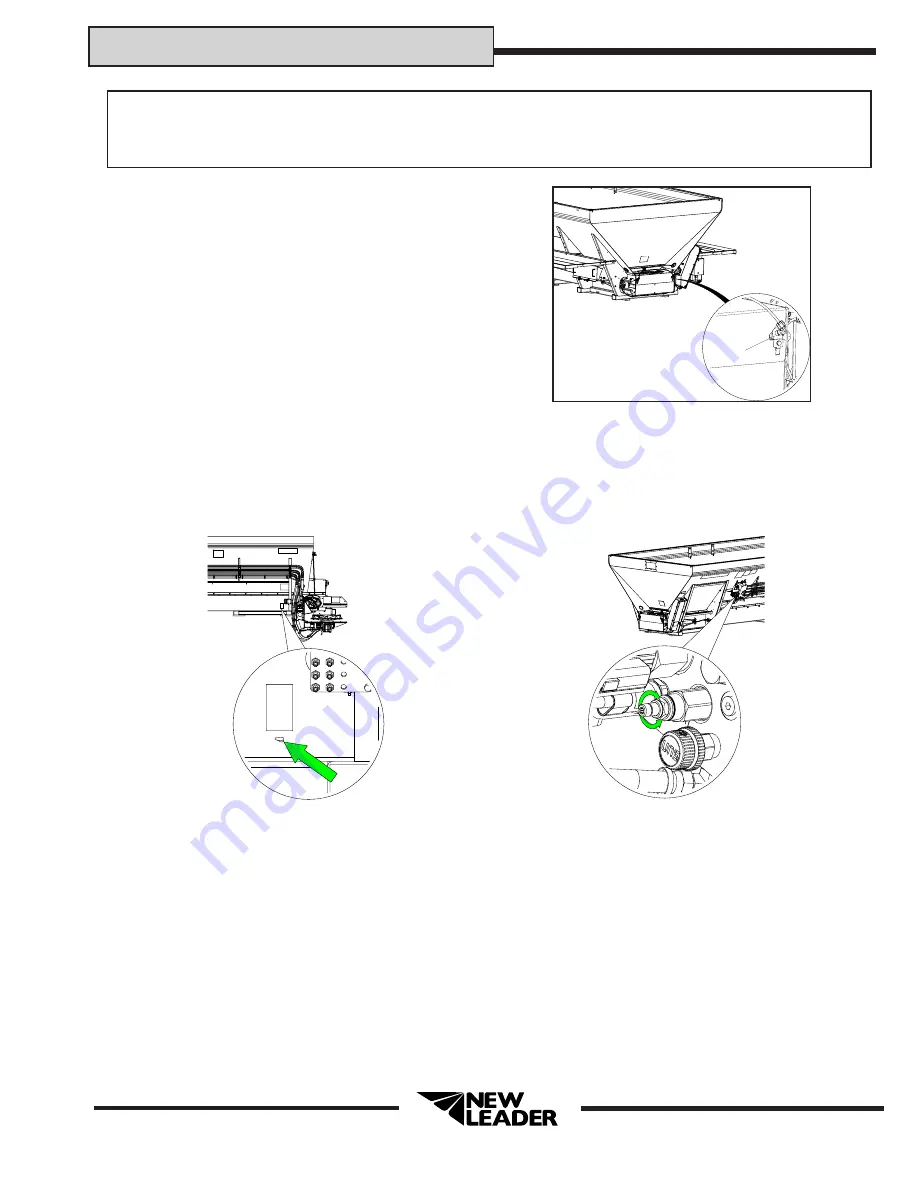

Lubricate conveyor chain via display at an interval

of 10 hours of spreading, or at the end of each

day of usage�

Tension

Proper chain tension is a factor in chain and sprocket

life� Measuring from rear of unit, conveyor should

touch at 36” - 40” (91 - 102cm) mark, and top of

chain should appear between MIN and MAX lines

in sight window (Figure 1)� If manual adjustments

need to be made, on valve block, loosen jam nut,

turn counterclockwise to lower tension, or turn

clockwise to increase tension (Figure 2)� All tension

adjustments must be made when machine is

unloaded and conveyor running 15-20 RPM�

NOZZLE

Figure 1

Figure 2A

Figure 2B

Over-tensioning of conveyor chain will lead to excessive load on the system which will cause excessive

chain and sprocket wear and can cause extremely high starting pressures� Under-tensioning allows

conveyor chain to “wrap” around drive sprockets and not exit sprocket freely, causing excessive excessive

chain stretch and surging of the conveyor which will result in interrupted flow of material to the spinners.