2-49

87519804 NA

Issued 11-06

Bur

CHAPTER 2 - 667TA ENGINE OVERHAUL

ENGINE REPAIR MANUAL

BS06K064

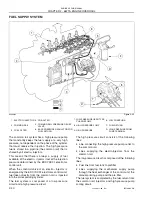

Figure 2-63

The figure above shows the low pressure fuel

passages inside the pump. The figure shows the

main plungers supply passage (4), the individual

plunger supply passages (1, 3, 6), the passages

utilized for lubrication of the pump (2), the high

pressure regulator (5), the 5 bar (72 psi) pressure

regulator valve (8) and the fuel discharge passage

(7).

The high pressure regulator (5) determines the

quantity of fuel which the high pressure plungers

deliver to the common rail. Excess fuel flows out

through passage (9).

The regulator valve (8), is designed to maintain a

constant pressure of 5 bar (72 psi.) at the high

pressure regulator inlet.

BS06K065

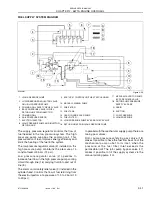

Figure 2-64

The figure above shows the fuel flow under high

pressure running through the exhaust galleries of the

pumping elements.

THEORY OF OPERATION

The cylinder is filled through the cap intake valve

only if the supply pressure is suitable to open the

delivery valves set on the pumping elements about

2 bars (29 psi.).

The amount of fuel supplying the high pressure pump

is metered by the high pressure regulator. The high

pressure regulator is controlled by the EDC7UC31

control unit through a PWM (pulse width modulated)

signal.

When fuel is se nt to a pump ing elem ent, th e

corresponding piston is moving downwards (suction

stroke). When the piston stroke is reversed, the

intake valve closes and the fuel in the pumping

element chamber, is compressed into the rail.

The generated pressure makes the exhaust valve

open and the compressed fuel reaches the high

pressure circuit.

The pumping element compresses the fuel till the top

dead center (delivery stroke) is reached. Afterwards,

the pressure decreases till the exhaust valve is

closed.

The pumping element piston goes back towards the

bottom dead center and the remaining fuel is

decompressed.

1. INLET TO HIGH PRESSURE PLUNGERS

2. PUMP LUBRICATION PASSAGES

3. INLET TO HIGH PRESSURE PLUNGERS

4. MAIN PLUNGERS SUPPLY PASSAGE

5. HIGH PRESSURE REGULATOR VALVE

6. INLET TO HIGH PRESSURE PLUNGERS

7. CHARGE PRESSURE REGULATOR DRAIN PASSAGE

8. CHARGE PRESSURE 5 BAR (72 PSI) REGULATOR VALVE

9. FUEL DISCHARGE FROM HIGH PRESSURE REGULATOR

VALVE INLET

1

9

3

4

7

6

2

5

8

1. FUEL EXHAUST FLUE

2. FUEL EXHAUST FLOWING FROM PUMP WITH

CONNECTOR TO HIGH PRESSURE LINE FOR

COMMON RAIL

3. FUEL EXHAUST GALLERY

3

2

1

Summary of Contents for 667TA/EBF

Page 4: ...SECTION 1 ENGINE REPAIR MANUAL II Issued 11 06 Bur 87519804 NA NOTES ...

Page 8: ...1 2 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 16: ...1 10 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 22: ...2 4 Issued 11 06 Bur 87519804 NA CHAPTER 2 667TA ENGINE OVERHAUL ENGINE REPAIR MANUAL NOTES ...

Page 144: ...3 2 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...

Page 150: ...3 8 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...