2-84

Issued 11-06

Bur

87519804 NA

CHAPTER 2 - 667TA ENGINE OVERHAUL

ENGINE REPAIR MANUAL

STEP 49

BS06K269

Figure 2-142

CYLINDER BORE DIMENSIONS AND SPECIFICATIONS

IMPORTANT:

In case of reconditioning all the bores

must be machined to the standard increments of over

sized bores 0.5mm (0.02in.).

Check the main bearing seats as follows:

•

Install the bed caps on the supports without

bearing.

•

Tighten the fastening bolts to the specified torque.

•

Check with a internal comparator, that the seat

diameter is the same as the specified value.

I f a va l u e i s fo u n d o u t o f t o l e r a n c e r e p l a c e

crankcase.

CHECKING THE CRANKCASE CYLINDER HEAD

MATING SURFACE

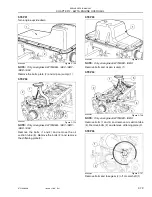

STEP 50

BS06K270

Figure 2-143

Verify that the crankcase cylinder head mating

surface does not show any warping. This check can

be accomplished by taking out dowels (4), with a

straight edge (2) and a thickness gauge (3). If there

are any deformed areas, resurface the block. The

warpage must not be greater than 0.075mm

(0.0030 in.).

IMPORTANT:

When the repair work has been

completed, check that the protrusion of the piston

from the bore is not greater than the specified value.

After flattening, restore the bore countersink, as

shown on page 2-84.

4

2

3

1

Summary of Contents for 667TA/EBF

Page 4: ...SECTION 1 ENGINE REPAIR MANUAL II Issued 11 06 Bur 87519804 NA NOTES ...

Page 8: ...1 2 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 16: ...1 10 Issued 11 06 Bur 87519804 NA CHAPTER 1 DIAGNOSTICS ENGINE REPAIR MANUAL NOTES ...

Page 22: ...2 4 Issued 11 06 Bur 87519804 NA CHAPTER 2 667TA ENGINE OVERHAUL ENGINE REPAIR MANUAL NOTES ...

Page 144: ...3 2 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...

Page 150: ...3 8 Issued 11 06 Bur 87519804 NA CHAPTER 3 CHARGING AND START UP ENGINE REPAIR MANUAL NOTES ...