© NEC Corporation 2019 39

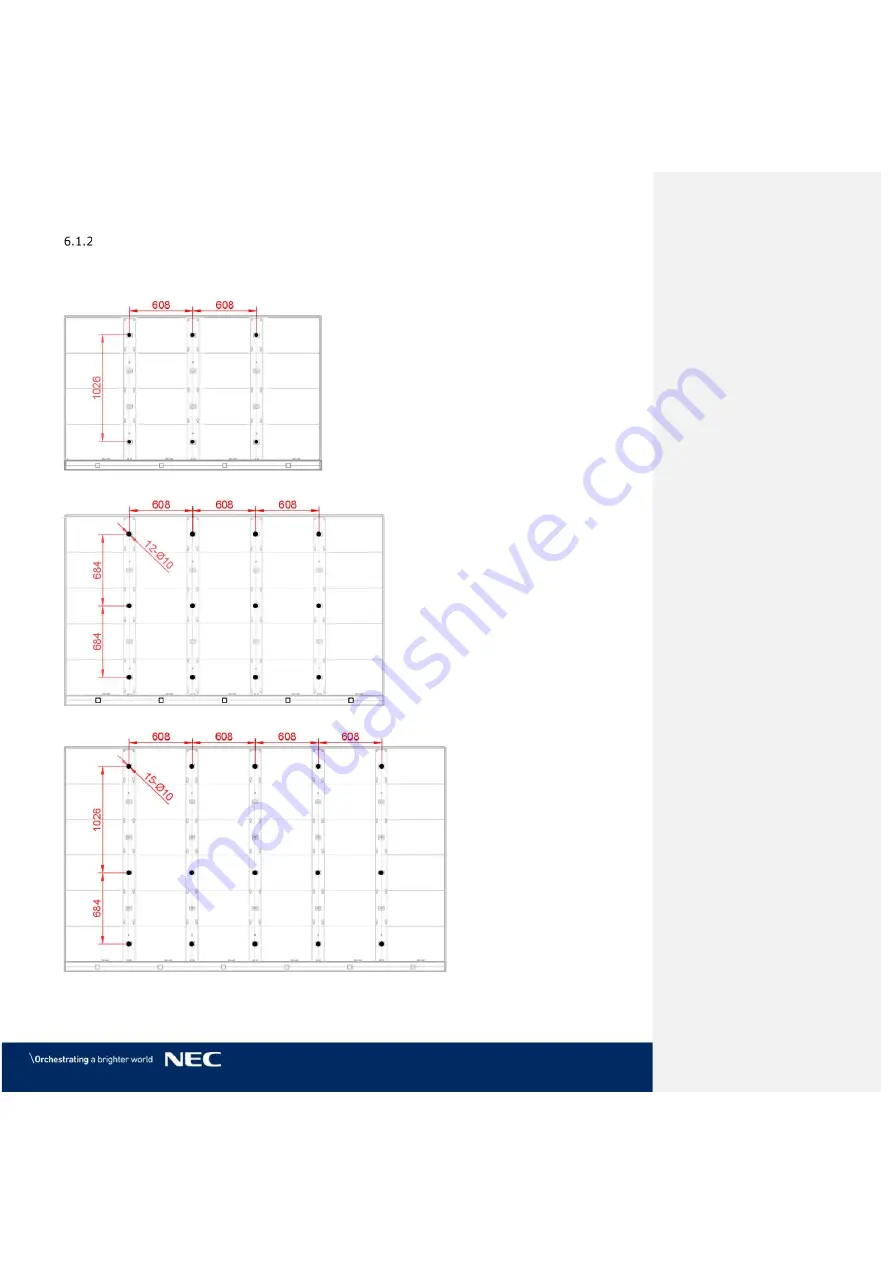

Draw and Mark the Anchor Positions on Wall

Start from the middle and mark the positions for the anchor points to drill out. (See

markings in figures below or the dimensions in Table 8.)

Use the spirit level to check the vertical alignment of the marks before drilling.

Figure 42: Positions for Anchor Points: 4×4 Frameset

Figure 43: Positions for Anchor Points: 5×5 Frameset

Figure 44: Positions for Anchor Points: 6×6 Frameset