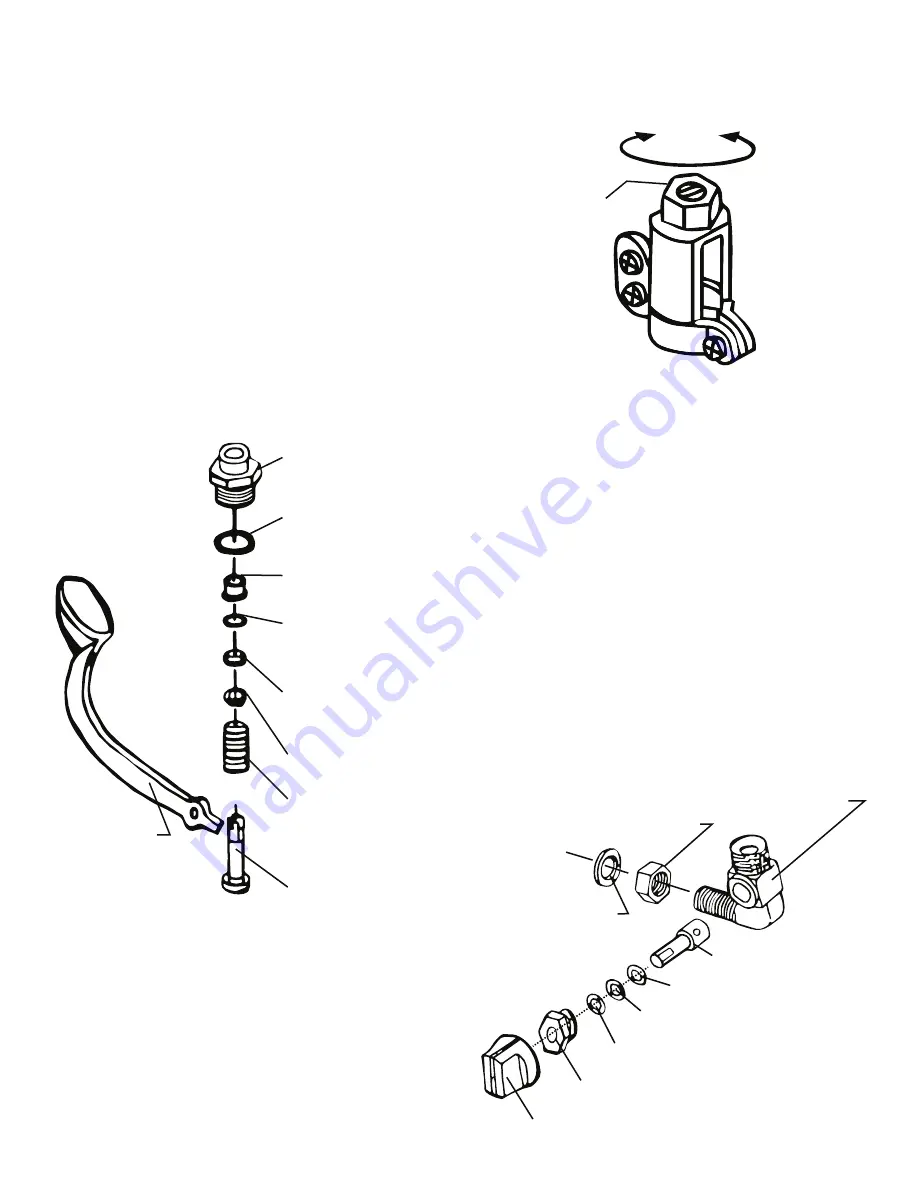

- Adjustment of Steam-Flow

This type of iron is so designed that the

steam-flow from its base-plate can be

adjusted. As shown in the following picture,

first unfasten the plastic nut on top of the

steam valve. Then, the steam-flow can be

decreased by turning the control-screw

clockwise with a s screwdriver, and vice versa

- Remove valve joint with spanner.

- Further, remove wire, teflon bushing, O-ring,

spindle washer and spring on this turn (see

below drawing).

- After finishing checking and replacement,

assemble on the reverse turn.

- When assembling finished, install it on the

iron as follows:

- Insert the wire into the spindle again.

- Install the metal fittng and the lever at last.

Note:

When assembling, be sure to wind the seal

tape on the valve joint

Valve Joint

Copper Packing

Teflon Bushing

O - Ring (P6)

Cap Seal

Spindle Washer

Valve Spring

Valve Spindle

Push Lever

(ie. the steam-flow can be increased turning

the screw counter-clockwise).

Back-up Ring (Wht.)

Plastic Nut

Decrease

Increase

Be sure to refasten the plastic nut after the

adjustment is completed. Please note that the

above adjustment is solely intended for

precision control of the steam-flow from the

iron base-plate, this is completely separate

from the steam pressure adjustment on the

boiler.

- Drain

if water drops or much drain come out with

steam, check and treat as follows.

- Abnormal pressure of the steam boiler.

Consult your agent or our office.

- Pipe line abnormality occured.

Consult our office.

- Inconvenience of draining function occured.

Consult our office or refer to drawing below

and check the drain valve.

Drain Valve Body

Copper Packing

Spindle

Jam Nut

O-Ring(Viton) (Blk.)

O-Ring(Silicone)(Pnk.)

Spindle Sopper Screw

Drain Valve Knob