10. FITTING THE MIXER VALVE

CONCEALED OPTION

IMPORTANT: Ensure that you have read through section 7. IMPORTANT INSTALLATION INFORMATION before

starting to fit the mixer valve.

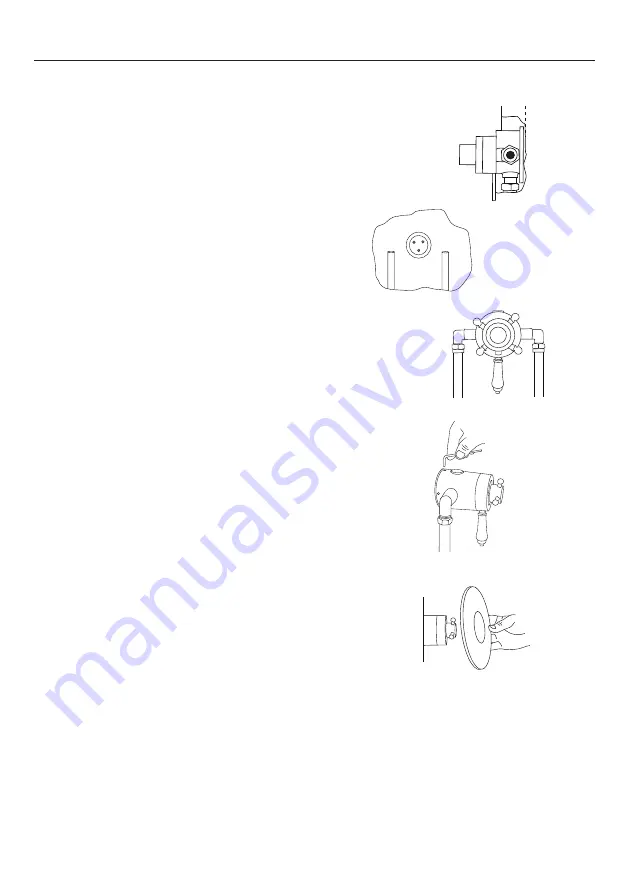

1. The fitting of the mixer valve is essentially the same

as described for the exposed option, except that the

mixer valve is fixed to the wall between 50mm and

70mm below the finished surface of the shower. A

circular hole between 150mm and 173mm should

be enough to fit the mixer valve (Fig 1).

2. The supply pipework can be plumbed from above

or below but must finish at the suitable connections

which should be at 155mm centers. Connect the

15mm pipework using standard compression nut

and olives.

NOTE: You should measure the distance between the

outlets on the mixer valve you are fitting to determine

the exact distance.

3. Complete the fitting of the pipework and the tiling

leaving the pipework as shown. The wall plate

should be attached firmly between 50mm and

70mm below the finished surface. Remove the back

plate from the mixer valve by removing the retaining

screws. Put the plate in the centre between the feed

pipes and mark the screw positions, check this fits

by holding the mixer valve in position. Drill plug and

screw the back plate to the wall (Fig 2).

4. Position the mixer valve onto the two water feed

pipes and onto the wall bracket. Tighten up the

compression nuts to hold the mixer valve in place

(Fig 3).

NOTE: Make sure the mixer valve outlet is pointing

down and the hot feed is onto the left side marked

with a red indicator.

5. Replace locking screws to hold the mixer valve onto

the wall plate (Fig 4).

6. A pipe must be fitted from the outlet of the mixer

valve to the location of where you wish to position

the wall outlet. This pipe must have a ½” female

connection attached into which the wall outlet can

be fitted.

NOTE: Once the mixer valve and wall outlet are

fitted, prior to fitting the trim plate disc ensure all

connections are watertight. This can be done by

reconnecting the water supplies and checking the

connections when running the shower and when the

shower is off.

7. The trim plate disc is fitted by unscrewing the

handles and pushing it onto the mixer valve until

flush with the tiles (Fig 5).

8. Fit riser rail as described in the riser rail fitting

instructions. Silicone should be used to seal the

outside edge of the trim plate disc to the tiles.

NOTE: Sufficient space should be left behind the trim

plate disc to allow access to the elbows for servicing.

5

4

3

1

2

60mm

Minimum

Summary of Contents for Atmos Traditional

Page 14: ...NOTES...

Page 15: ...NOTES...