M1.1.TPT1300-TPT2000.NLFREN 08122017

10

NL

Gebruik nooit een hogedrukreiniger om de machine schoon te maken. Water kan in kleine

ruimtes binnendringen en assen, katrollen, lagers of de motor beschadigen. Het gebruik van een

hogedrukreiniger vermindert de levensduur en de efficiëntie van de machine.

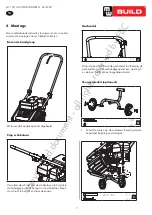

De V-riemen controleren

De V-riemen moeten steeds in goede staat zijn, voor een goede overbrenging van de motor naar de excentrische as.

1. Zet de motor stil en laat deze afkoelen.

2. Verwijder de beschermkap, om de V-riemen te kunnen bereiken.

3. Controleer de goede staat van de V-riemen. Als een riem gebarsten, gerafeld of glad is, vervang beide V-riemen.

4. Controleer de riemspanning door in het midden te drukken. De riem moet zich van 9 tot 12 mm (3/8 tot 1/2”) laten

indrukken als u met de vinger duwt.

Controleer de riemspanning op een nieuwe machine of na installatie van een nieuwe riem na 20 werkuren, en daarna

alle 50 werkuren.

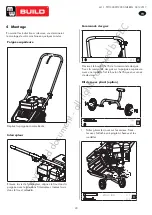

De riemspanning instellen

De juiste riemspanning is belangrijk voor goede prestaties. Een correcte instelling zorgt voor een lange levensduur van de

riemen. Een te onjuiste spanning kan de riem beschadigen.

1. Verwijder de motorkap of het waterreservoir.

2. Draai de 4 montagebouten van de motor los (verwijder deze niet), net genoeg om de motor te kunnen bewegen.

PLATE COMPACTOR

12

GB

1.

2.

3.

4.

On new machines or after installing

a new belt, check belt tension after

first 20 hours of operation. Check

and adjust belt every 50 hours

thereafter.

Checking V-Belt(s)

To ensure optimum power transmission from

the engine to the eccentric shaft, the V-belt(s)

must be in good condition and operate under

proper tension.

MAINTENANCE

Maintaining your compactor will insure long

life to the machine and its components.

Preventive Maintenance

Turn off engine. Engine must be cool.

Keep the engine’s throttle lever in its

SLOW position, and remove spark plug

wire from spark plug and secure.

Inspect the general condition of the

plate compactor. Check for loose screws,

m i s a l i g n m e n t o r b i n d i n g o f m o v i n g

parts, cracked or broken parts, and any

other condition that may affect its safe

operation.

R e m o v e a l l d e b r i s f r o m t h e p l a t e

compactor with a soft brush, vacuum,

or compressed air. Then use a premium

quality lightweight machine oil to lubricate

all moving parts.

Clean the bottom of the compactor base

as soon as it begins to pick up soil being

compacted. The unit can not do a good

job if the bottom surface is not smooth

and clean.

Replace spark plug wire.

1.

2.

3.

4.

5.

6.

Never use a “pressure washer” to

clean your plate compactor. Water

can penetrate tight areas of the

unit and cause damage to spindles,

pulleys, bearings, or the engine.

The use of pressure washers will

result in shortened life and reduce

serviceability.

Tensioning V-Belt(s)

P r o p e r b e l t t e n s i o n i s c r i t i c a l t o g o o d

performance.

Proper adjustment will assure long belt life.

Too much or too little belt tension will cause

premature belt failure.

Turn off engine. Engine must be cool.

Remove the belt guard to access the

V-belt(s).

Check the condition of the V-belt(s). If

any V-belt is cracked, frayed, or glazed, it

should be replaced as soon as convenient.

Check the V-belt tension by squeezing

them in the center. The normal deflection

on each side should be 9mm (3/8” to

13mm (1/2” with moderate pressure from

your thumb or finger.

Basic Models

29242UK00M101-改.indd 12

2016/6/23 17:58:37

Basis model

PLATE COMPACTOR

13

GB

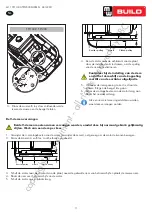

When adjusting the belt(s), make

sure that the clutch pulley is in

alignment with exciter pulley.

Loosen the jam nuts B, leaving enough

space between the nut and bracket.

When the V-belt tension is correct, tighten

the jam nuts B against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

Push engine toward the back of the plate

by turning the adjustment bolts A to

remove any slack in V-belt(s).

Remove the metal cover or water tank.

Loosen 4 engine mount bolts (do not

remove) only enough to move the engine

forward.

3.

5.

4.

1.

2.

6.

7.

V-belt

Clutch pulley

Exciter pulley

If the adjustment bolts have no

more adjustment left, the belt(s)

may have to be replaced.

Compactor with optional water sprinkler kit

29242 / 29255 / 29260 / 29265

29240

A

B

A

A

B

B

29242UK00M101-改.indd 13

2016/6/23 17:58:38

Trilplaat met optionele watersproeier kit

copyrighted

document

- all

rights

reserved

by

FBC