- 53 -

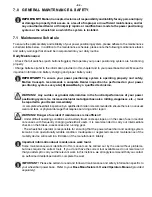

7.2 Safety Inspection Checklist

7.0 GENERAL MAINTENANCE & SAFETY

7.0 GENERAL MAINTENANCE & SAFETY

Item

Initially

Monthly

6 Months

Periodically

Batteries

load test batteries (individually)

X

X

ensure batteries are clean (free from corrosion/ moisture/

dirt)

X

X

ensure connections are tight and clean

X

X

Electrical / Wiring Harnesses

check for pinches or pulls in wiring (over full range of

seating system)

X

X

Inspect for wear & tear damage to wires

X

X

ensure connections are secure

X

X

Actuators (where applicable)

ensure actuator rod ends are properly pinned

X

X

ensure no interference/ sticking during system operation

(over full range of seating system)

X

X

Inspect for excessive noise or grinding

X

X

Hardware and Components

inspect mounting hardware (seating system to power-

base)

X

X

inspect all adjustment hardware to ensure nuts and

screws are secure (i.e. side rails, recline module,

legrests/foot plates/receivers

X

X

inspect for loose parts /rattling sounds- ensure all nuts

and screws are secure

X

X

Inspect that all pivot points are operating smoothly &

freely and secured (do not overtighten)

X

X

Inspect Anti-Dive/ Anti-Tip devices to ensure they are

functioning correctly* and inspect for damage. (*refer to

powerbase owners/operators manual)

X

X

Limit Switches

ensure electronic anti-tip latch system functions properly

(Quickie S626/S636/S646 only)

X

X

check limit switch settings

X

X

ensure DLO functions correctly

X

X

Pivots, Glide Blocks & Track Maintenance

ensure slide channel is free from dirt/ dust/ grime

X

X

lightly lubricate main pivot points, using a general

purpose oil (see Section 7.3 - Lubrication)

X

Summary of Contents for F Series

Page 2: ......