IPT

2

6

The Interface Solution Experts

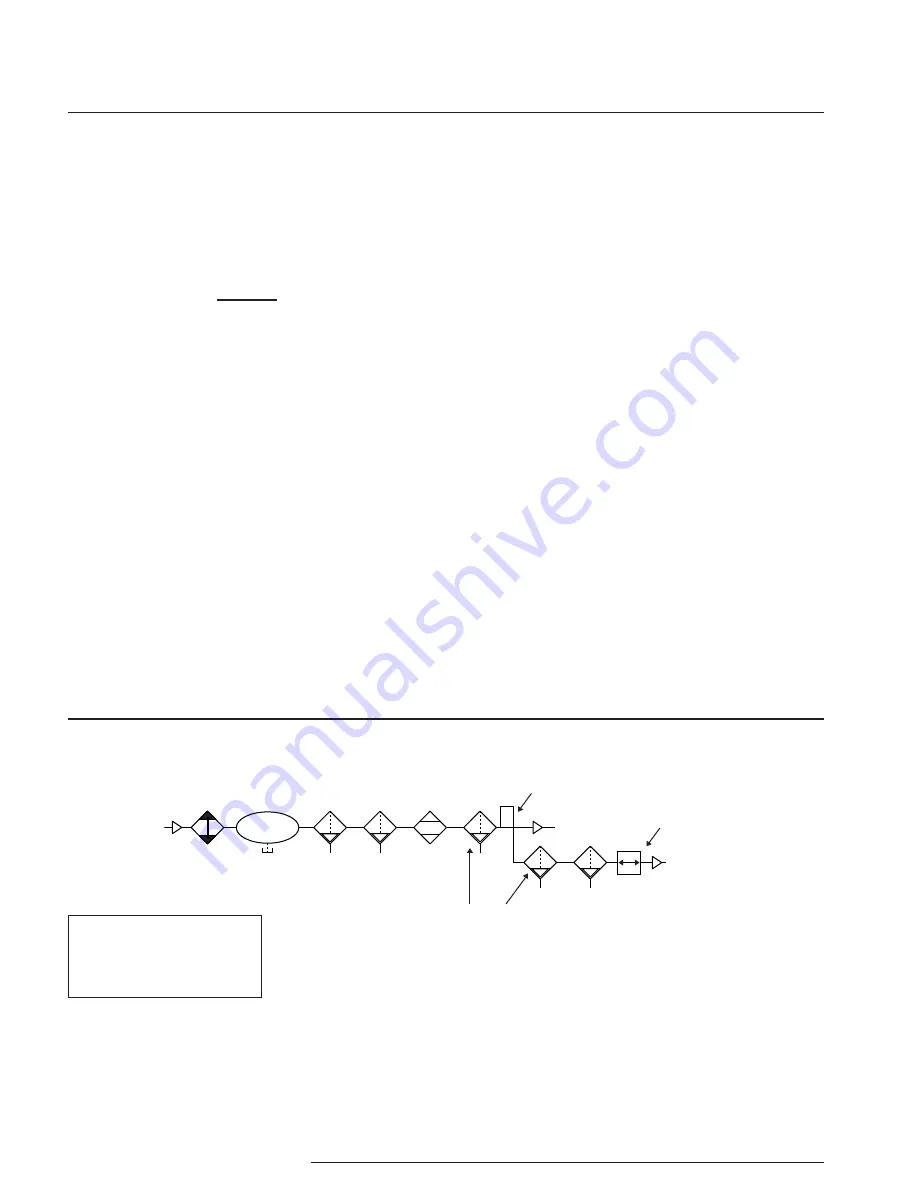

Cooler

Receiver

5-Micron General

Purpose Filter

High-Efficiency

Coalescing

Filter

5-Micron General

Purpose Filter(s),

One Main or Multiple

on Branch Lines

Dessicant

Dryer

Extend Branch Line(s) Above Main

Line to Avoid Passing Liquids

0.01-Micron

High Efficiency

Coalescing

Filter(s)

{

Purified Air

For IPT

2

's

Main Line to

Other Branches

Keep Short

Pressure

Regulator

D

The use of coalescing fi lters with retention of 0.01

micron particles and droplets is recommended;

they remove all undesirable traces of oil and water

droplets. Proper placement with respect to the

regulator may eliminate the need for dryers, except

when coalescing fi lters are exposed to freezing

temperature (keeping in mind that the dew point of the

purifi ed air must be kept below worst case ambient).

Figures 1 and 2 illustrate typical non-redundant

systems with multiple branch lines. They both work

in any environment above freezing and diff er only

in the placement of the general purpose fi rst-stage

fi lter. Gauges, valves, and diff erential pressure

indicators (for fi lter service monitoring) are not shown.

It is recommended that fi lters with integral service

life indicators or diff erential pressure indicators be

used to help ensure proper servicing, as well as

redundancy to avoid shutdown during servicing.

Figures 1 and 2 diff er in the method used to

remove water. The use of a desiccant type dryer

(Figure 2) requires upstream fi ltration to prevent

oil contamination of the desiccant, as well as

downstream fi ltration, to prevent desiccant fi nes from

introducing new contamination.

The service life of an IPT

2

is directly proportional to

the cleanliness and dryness of its air supply. The

small cost of providing high-quality air ensures a

longer, more trouble-free service life for the unit.

Application Information

Any approach to providing good instrument air

quality should evaluate the worst case air fl ow and

ambient temperature of the location. This is required

to determine sizing of the air system elements. A

knowledge of yearly humidity cycles is also important

for this evaluation.

Caution:

Before placing IPT

2

s in service, all pneumatic lines

and mounting blocks or headers (SIRs or RIRs)

should be "blown down" to purge contamination and

condensation deposited during piping and installation.

Also blow down lines to loads, since all output air

vents back through the IPT

2

, and there are never

fi lters installed to trap these contaminants (normally

only present at start-up). It is recommend this be

done for at least an hour, longer if there is evidence of

water or oil coming through.

The IPT

2

requires periodic maintenance. Service in

the fi eld is limited to visual inspection and cleaning of

the input nozzle fi lter screen on the IPT

2

and servicing

of the compressed instrument air fi ltration system.

The unit may be returned to the factory for complete

disassembly, cleaning, and servicing on a periodic

basis.

Figure 1. Non-Redundant System with Desiccant Dryer

Note: All fi lters should have

automatic drains and service

life indicators to show when

elements need changing.