OPERATIONS INSIDE THE ENGINE COMPARTMENT

PERIODIC INSPECTION AND MAINTENANCE

2-20

CAUTION

•

The reinstallation histories of the removed

injection pipe are up to five times. To count

how many times the injection pipe is rein-

stalled, record the number of the reinstalla-

tion histories on the service booklet by

adding this latest number of the histories,

which is usually "1", to the previous one. Use

a new injection pipe when the total reinstalla-

tion history numbers reach five times, or

when the injector or common rail is replaced.

In this case, record "a new injection pipe, the

number of the reinstallation histories is zero"

on the service booklet.

•

When the injection pipe is reinstalled, confirm

there is no foreign material on the seal sur-

face or in the pipe and then install it not to

deviate from the axis, fitting the seal surface.

11.Install the EGR pipe.

NOTE: Since the fuel injection pipe connection on

the fuel injector assembly side is located inside the

engine (rocker cover), visual check for fuel leak can-

not be performed. Due to this, use the oil leak detec-

tion agent to check for fuel leak.As for other fuel

injection pipe and the fuel supply pump pipe connec-

tion, visually check for fuel leak.

NOTE: The oil leak detection agent detects oil leak

by colour change when it is applied to the area to be

checked. For details on how to use the product, refer

to the instruction manual.

CAUTION

Degrease the area between the flare nut and the

pipe of the fuel injection pipe by fully spraying

the parts cleaner.

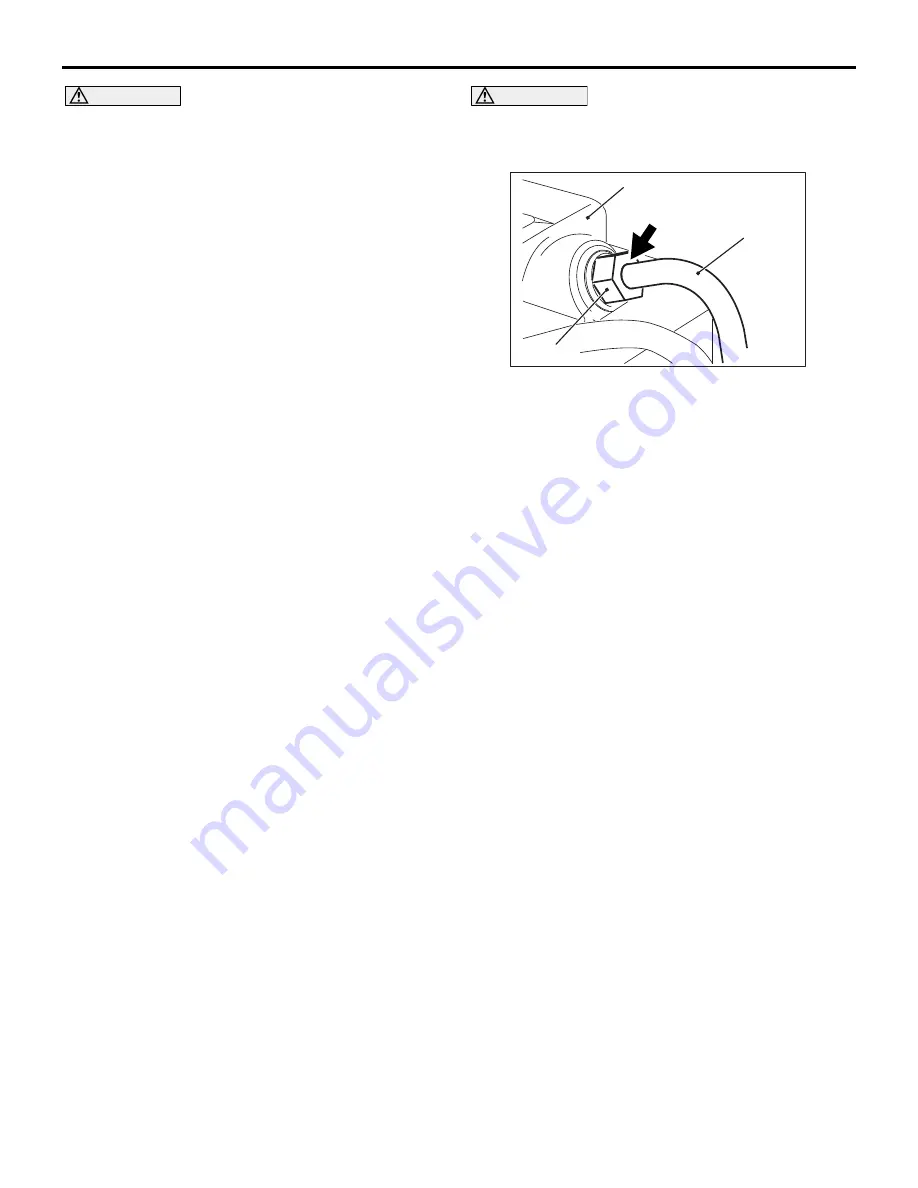

12.Carefully degrease the flare nut at the fuel injector

assembly side of the fuel injection pipe with the

parts cleaner (MZ100387) or equivalent.

13.If the parts cleaner remains in the area between

the flare nut for connection and the fuel injection

pipe, the oil leak detection agent detects that

there is a fuel leak. Therefore, use an air gun to

blow off the remaining parts cleaner and fully dry

the degreased area.

14.Apply the oil leak detection agent to the flare nut

and the pipe of the fuel injection pipe.

NOTE: It is easy to detect the oil leak when the oil

leak detection agent is dry enough because the

colour changes clearly. Use a dryer to dry the oil

leak detection agent when it is hard to dry.

NOTE: Since the fuel injection pipe connection on

the fuel injector assembly side is hard to check for

fuel leak. Due to this, use the oil leak detection

agent to check for fuel leak. As for other fuel injec-

tion pipe and the fuel supply pump pipe connec-

tion, visually check for fuel leak.

ACA00283 AC

Fuel

injection

pipe

Rocker cover

Flare nut

Summary of Contents for Pajero Sport 2013

Page 6: ...NOTES...

Page 16: ...BODY PRE DELIVERY INSPECTION 1 10...