5 - 11 5 - 11

MELSEC-Q

5 UTILITY PACKAGE (GX Configurator-DA)

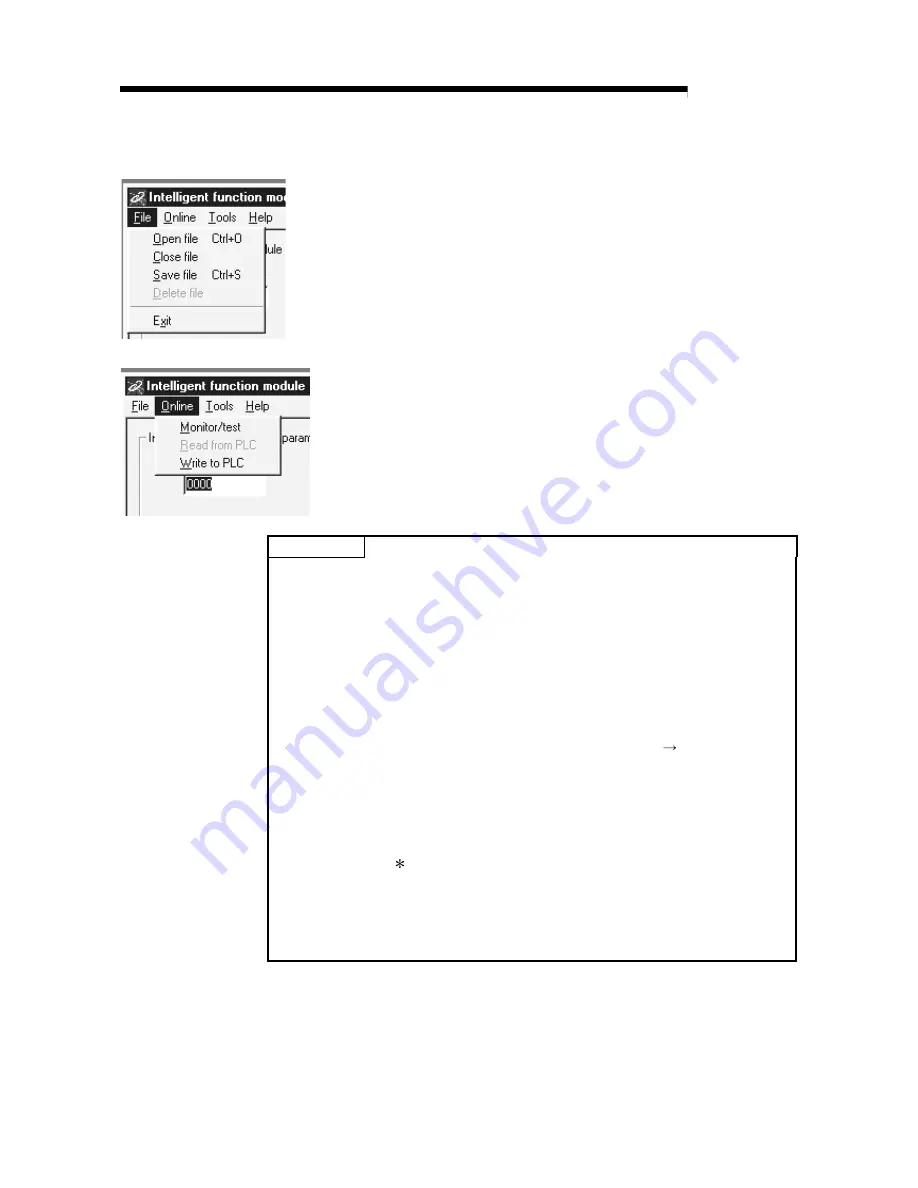

(3) Menu bar

(a) File items

With file operation, the intelligent function module parameters for the project

opened by GX Developer can be processed.

[Open file]

: Reads the parameter file.

[Close file]

: Closes the parameter file. If revisions were made, a

dialog box asking whether to save the file appears.

[Save file]

: Saves the parameter file.

[Delete file]

: Deletes the parameter file.

[Exit]

: Quits the intelligent function module utility.

(b) Online items

[Monitor/test]

: Starts the monitor/test module selection screen.

[Read from PLC] : Reads the intelligent function module parameters from

the CPU module.

[Write to PLC]

: Writes the intelligent function module parameters to the

CPU module.

POINT

(1) Saving the intelligent function module parameter files

Since files cannot be saved using the GX Developer project save operation,

save the files using the module selection screen for intelligent function module

parameter setting described above.

(2) Reading from and writing to PLC operations for the intelligent function module

parameters using GX Developer

(a) After the intelligent function module parameters are saved in a file, they

can be read from and written into the PLC.

(b) Set the target PLC CPU using GX Developer [Online] [Transfer setup].

(c) When the D/A Conversion module is installed to the remote I/O station,

use "Read from PLC" and "Write to PLC".

(3) Checking for the required utility

The head I/O is displayed in the Intelligent function module utility setting

screen, but a " " may be displayed for the model name.

This means that either the required utility is not installed or that the utility

cannot be started from the GX Developer.

Check for the required utility in [Tools] - [Intelligent function utility] - [Utility

list...] in GX Developer, and set it.