-

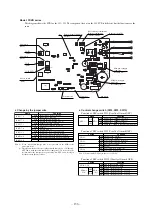

150

-

L

N

E

TB

TB

Red

White

Y/NG

LED1

Red

T1

T5

Red

White

Blac

k

Or

ange

Y

ello

w

U

V

W

T6

T7

T8

CM

F2 (250V 20A)

CnTR

Control PCB

Power transistor module

CNI3

T2

T4

6

DC280V

F3 (250V 1A)

F5 (20A)

4

3

2

1

CNI2

FM

0

T21

T22

Sub PCB

(Noise filter)

T24

T25

T26

T30

T27

T28

CNI1

Orange

Gray

To indoor unit

Brown

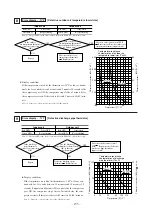

Temperature [ T ] (˚C)

T< 80˚C

T >80˚C

100

50

0

10

5

0

Thermistor resistance (k

Ω

)

[T

< =

80˚C

]

Thermistor resistance (k

Ω

)

[T

> =

80˚C

]

0

20

50

80

100 120

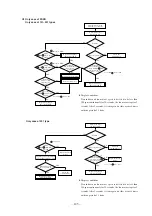

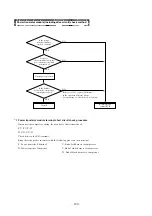

Power transistor thermistor temperature and

resistance characteristics check

Power transistor module

check: Is there a short cir-

cuit, open circuit or dam-

age? (See 160 page for the

check procedure.)

DC Reactor Continuity

Check: 50 m

Ω

or higher,

less than 100 m

Ω

.

Fuse Check: There should be continuity.

If faulty, replace the control PCB.

When the outdoor

unit fan motor is

abnormal:

(Refer to page 157)

Noise Filter Check:

There should be continuity.

There should be no shorts between phases.

LED1 (Red) Check

Light continuously :

Keeps flashing :

1~3 time flash :

Normal

EEV

Refer to 131 page

Power Supply Check

Measure the power supply at L.N.

(It is normal if it is AC 220/240V.)

❇

Fuse Check: There should be

continuity.

●

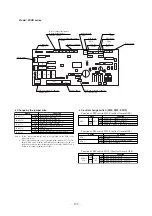

Outdoor unit check points

Check items with the *mark when the power is ON.

Outdoor Unit controller failure diagnosis circuit diagram

FDCVA151~251 type