6

ENGLISH

4. Selecting an installation site

•

Select a site with sturdy fixed surface sufficiently durable against

the weight of unit.

•

Before installing unit, the route to carry the unit to the installation

site should be determined.

•

Select a site where the unit is not affected by entering air.

•

Select a site where the flow of supply, return, exhaust and outdoor

air is not blocked.

•

Select a site where refrigerant piping and exhaust/outdoor ducts

can easily be led to the outside.

•

Select a site which allows the supply air to be distributed fully in room.

•

Select a location where the inspection opening can be installed.

•

Do not install unit at a site with oil splashing or steam in large quantities.

•

Do not install unit at a site where combustible gas may generate,

flow in, stagnate or leak.

•

Do not install unit at a site where equipment generating high frequency

waves (a high frequency wave welder for example) is provided.

•

Do not install unit at a site where fire detector is located at the

supply air side. (Fire detector may operate erroneously due to the

heated air supplied during heating operation.)

•

When special chemical product may be scatter all around such as

site chemical plants and hospitals, full investigation is required be-

fore installing unit. (The plastic components may be damaged de-

pending on the chemical product applied.)

•

Do not install this product in a refrigerated warehouse, heated swim-

ming pool or other location where the temperature and humidity

are significantly different.

(Failure to heed this warning may result in electrical shock or mal-

function.)

•

The electro-magnetic susceptibility has been chosen at a level that

gains proper operation in residential areas, on business and light

industrial premises and on small-scale enterprises, inside as well

as outside of the buildings. All places of operation are character-

ised by their connection to the public low voltage power supply

system.

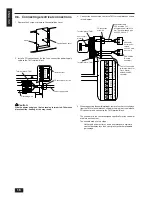

5. Installing the Fresh Master

5.1. Fixing hanging bolts

(Use M10 or M12 hanging bolts. The bolts and washers should be

supplied in the field.)

(Give site of suspension strong structure.)

Hanging structure

•

Ceiling: The ceiling structure varies from one building to another.

For detailed information, consult your construction company.

1

Reinforcing the ceiling with additional members (edge beam, etc.)

must be required to keep the ceiling at level and to prevent the

ceiling from vibrations.

2

Cut and remove the ceiling members.

3

Reinforce the ceiling members, and add other members for fixing

the ceiling boards.

•

Mount the washers (outer diameter of >21 mm for M10, >24 mm

for M12) and nuts obtained from a field supply onto the pre-recessed

hanging bolts (M10 or M12) also obtained from a field supply, as

shown in the figure.

4.1. Install the Fresh Master on a ceiling

strong enough to sustain its weight

Warning:

The unit must be securely installed on a structure that can sus-

tain its weight. If the unit is mounted on an unstable structure, it

may fall down causing injuries.

4.2. Securing installation and service

space

•

Select the optimum direction of supply airflow according to the con-

figuration of the room and the installation position.

•

As the piping and wiring are connected at the side surfaces, and

the maintenance is made at the same surfaces, allow a proper

space properly. For the efficient suspension work and safety, pro-

vide a space as much as possible.

4.3. Standard installation examples

Hanging bolt (M10 or M12)

Nut

Washer

Nut

EA

(exhaust)

Maintenance

space

Exhaust grille

Hanging bolt location

Inspection opening

Supply grille

OA

(outdoor)

Duct downward

gradient to wall

(more than 1/30)

Cistern tank

Deionizer

Duct (provided by

customer)

Hanging bolt

(provided by customer)

Deep hood or

weather cover

EA

(exhaust)

OA

(outdoor)

Drain pipe gradient to wall

(more than 1/100)

Supply pipe

Inspection

opening

Servicing

valve

Exhaust

grille

Supply

grille

RA

(return)

SA

(supply)

Summary of Contents for Fresh Master GUF-100RD3

Page 22: ...22 ENGLISH ...