16

OPERA

TION

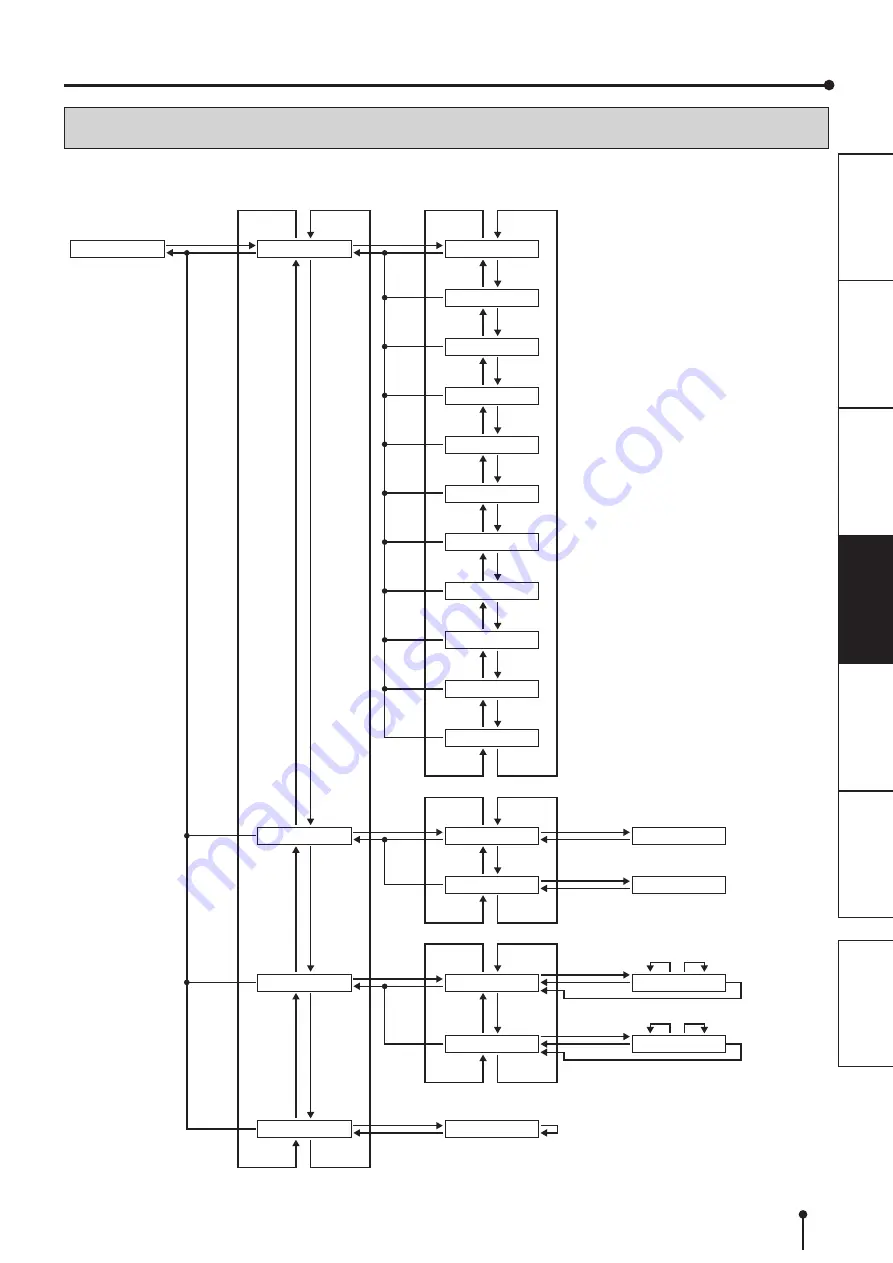

BUTTON OPERATION AND LCD INDICATION

Use the operator control panel buttons and LCD to review and change printer settings.

PRINTED: ******

PRINTER INFO>

READY[8x12]

PAPER LEFT: ***%

INK LEFT: ***%

MAIN FW: ******

FPGA: ******

TABLE: ******

SERIAL: ******

MODEL: ********

TPH MODEL: *****

TPH SN: ********

TPH RES: ****

10 LEVEL GRAY

CREATING

CREATING

TEST PRINTS>

WAIT TIME>

MAINTENANCE>

STATUS PRINT

WAIT TIME: ***

TIME OUT: ***

WAIT TIME: ***

TIME OUT: ***

CLEAR WASTE

ENTER

MENU

MENU

MENU

ENTER

ENTER

MENU

(Auto)

MENU

MENU

ENTER

MENU

ENTER

MENU

ENTER

ENTER

(Set value)

ENTER

(Set value)

ENTER

(Execute)

MENU

ENTER

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

-

+

-

-

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

MENU

MENU

MENU

-

+

-

+

+

-

+

-

+

(Change value)

-

+

(Change value)

(Print Test Pattern)

ENTER

(Auto)

(Print Test Pattern)

+

-

+

-

+

* Use the button shown in bold type.

USAGE