10

MAINTENANCE PROCEDURES

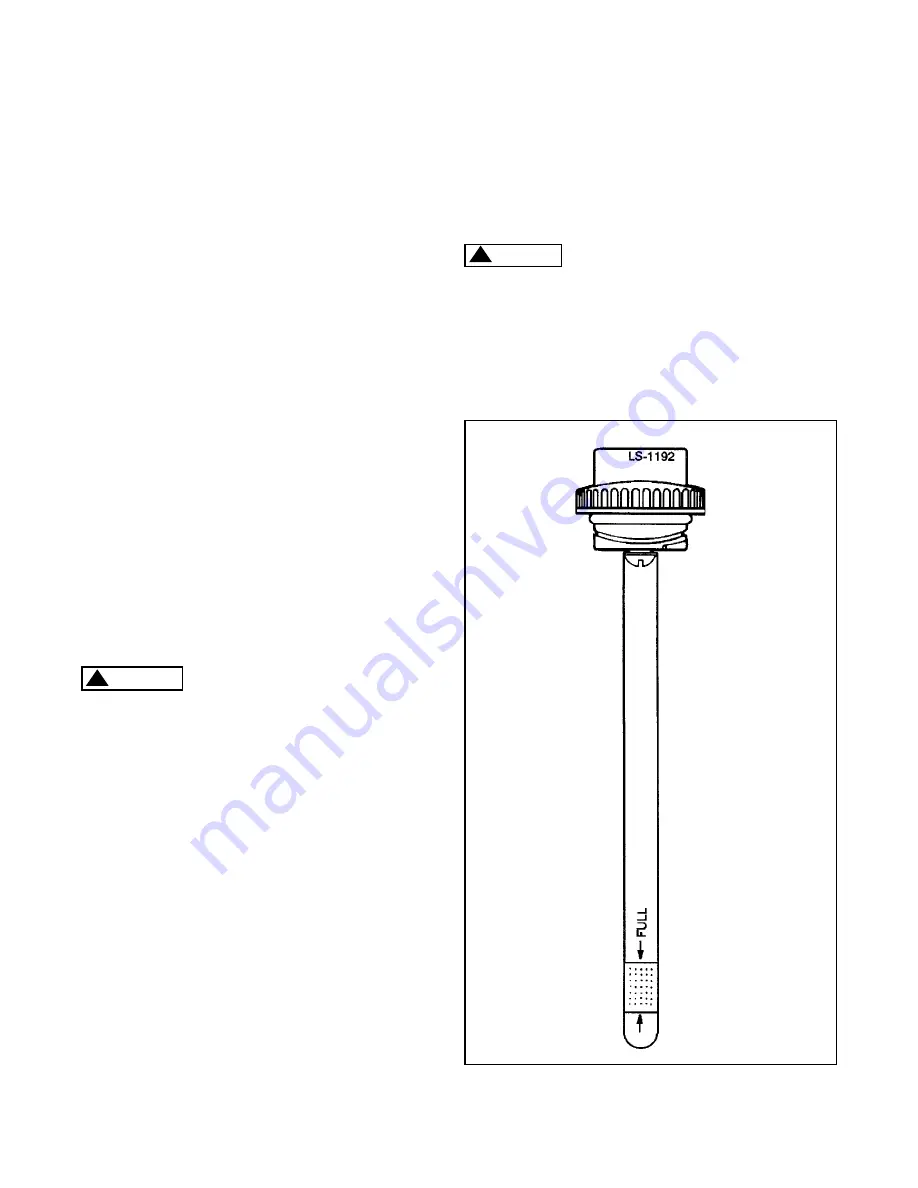

OIL FILL CAP AND DIPSTICK

NOTE: N.F.P.A. rule 58 8-1.4 states, “In the interest of

safety, each person engaged in installing, repairing,

filling, or otherwise servicing an LP-Gas engine fuel

system shall be properly trained in the necessary

procedures”.

3. Hose and Fuel Connections: Inspection: Check for gas

leaks by using a soapy water solution around all

connections with service valve turned on so the fuel

system is pressurized. Inspect all hoses for abrasions

and other signs of wear. Replace all damaged and worn

hoses. Fixing Leaking Joints: Uncouple bad joint, clean

joint and apply pipe sealing compound (use a Loctite

Pipe Sealant with Teflon or equivalent) to clean joint.

Re-couple the joint, tighten plus 1/2 turn. Recheck for

leaks.

4. Carburetor Air Filter:

NOTE:

Failure to service and clean

carburetor air cleaner may produce excessive carbon

monoxide emissions.

•

Remove cover from the air cleaner.

•

Remove foam pre-cleaner and use the same

procedure for cleaning the foam pre-cleaner.

•

Rinse in mild detergent and squeeze out excess

water, do not wring out.

•

Clean filter seal, making sure no dust is allowed

in the carburetor inlet.

•

Inspect paper element. Replace if dirty, bent or

damaged.

•

Install the clean paper element, pre-cleaner, and

attached air cleaner cover.

OIL CHANGE

Hot crankcase oil can cause burns if it

contacts the skin. Wear protective clothing and keep

fingers and hands clear when draining oil.

Used oil is harmful to the environment. Pour used oil into a

sealed container and deliver it to the nearest recycling

center or automotive service station.

CHANGING THE OIL

1. Run engine for 5 minutes to warm oil, then stop engine

by closing the service valve on the tank. Turn the key

to the off position.

2. Locate the oil drain located the right side of the engine

at its base. Remove the cap on the oil drain tube by

turning counter clockwise with a wrench.

3. Allow oil to drain completely into the receptacle.

4. Replace the cap by turning clockwise.

5. Remove oil fill cap. Always refer to the Engine Manual

for recommended oil and amount.

6. Check oil level with dip stick in oil fill cap. Add additional

oil if necessary.

NOTE: TO CHECK OIL ON THE

BRIGGS & STRATTON MODELS, SCREW THE CAP

IN AND OUT AGAIN. ALWAYS MAKE SURE THE

MACHINE IS SITTING LEVEL WHEN CHECKING OIL.

7. Replace fill cap. Hand tighten only.

CAUTION

!

If the oil level is low, add API Class SG or SH oil (also SG/

CD, SG/CE, SH/CD or SH/CE) having an SAE viscosity

grade appropriate for the expected temperatures, as

indicated by Table 1.

DO NOT FILL TO A LEVEL ABOVE THE FULL MARK ON

THE DIPSTICK. Drain the excess oil if too much has been

added.

Too much oil can cause high oil

consumption, high operating temperatures and oil

foaming. Too little oil can cause severe engine damage.

Keep the oil level between the Full and Add marks on

the dipstick.

Reinstall the dipstick and cap after checking or adding oil,

turning it clockwise until it is secure.

WARNING

!

Summary of Contents for M220021H13

Page 1: ...Mirage Propane Burnisher OPERATION SERVICE PARTS CARE Model M220021H13...

Page 2: ......

Page 16: ...13 ENGINE 13HP HONDA...

Page 18: ...15 ENGINE 13HP HONDA...

Page 20: ...17 WIRING DIAGRAM 13HP HONDA...