spring tension on the spring-hooking

pulley. Too much tension could break the

scale.

You can get just the shutter-speed

scale as a replacement part. Alternately,

you can replace the complete shutter-

speed indicator assembly; the assembly

includes the scale and the pulleys w ith the

spring already tensioned. There's an ad

vantage in replacing the com plete

assembly — if you replace just the scale,

you may encounter tracking and align

ment problems. That is, when you get the

" 0 " calibration centered in its window,

you may find that the ‘ ‘1000'' calibration

does not center. However, if the scale

breaks, you can normally make a satisfac

tory repair w itho u t replacing parts.

The break usually occurs at the point

where the scale cements to the wire-

hooking pulley. Part of the scale then re

mains cemented in place. Simply butt the

loose end against the end still attached to

the pulley. Then cement the loose end

w ith super glue.

Now slip the knot in one end of the

tungsten wire through the slot in the

wire-hooking pulley, Fig. 114. W rap the

tungsten wire 2-1/2 turns around the

wire-hooking pulley in a clockwise direc

tion (as seen from the back). It's a little

tough to wrap the free end of the tung

sten wire around the wire-hooking pulley

— you do n 't have a lot of room. But

there's another technique you may find to

be easier.

Before you connect the

tungsten wire, rotate the wire-hooking

pulley fully clockwise (as seen from the

back). The scale then wraps around the

wire-hooking pulley, adding tension to

the spring.

Next, while holding the wire-hooking

pulley to maintain the spring tension,

connect the tungsten wire. You may have

to allow the wire-hooking pulley to rotate

slightly counterclockwise until you can

reach the slot. If you need both hands to

connect the tungsten wire, you might use

a piece of masking tape to hold the

spring-loaded pulley in place. Here, it's

critical that you d o n 't accidentally release

the pulleys. W ith so much tension on the

spring, the scale would definitely break.

A fter you connect one end of the tung

sten wire, hold the other end as shown in

Fig. 115. Now let go of the spring-loaded

pulley and allow the spring to slowly draw

the scale from right to left. The tungsten

wire should wrap itself tw o turns around

the wire-hooking pulley. You need then

wrap on only 1/2 additional turn.

You may wish to put a piece of mask

ing tape over the wire-hooking pulley to

keep the tungsten wire in place. Then

route the tungsten wire under pulley #2,

Fig. 116. Notice in Fig. 116 that we've

temporarily repositioned the flex circuit to

clear pulley #2. Normally the flex covers

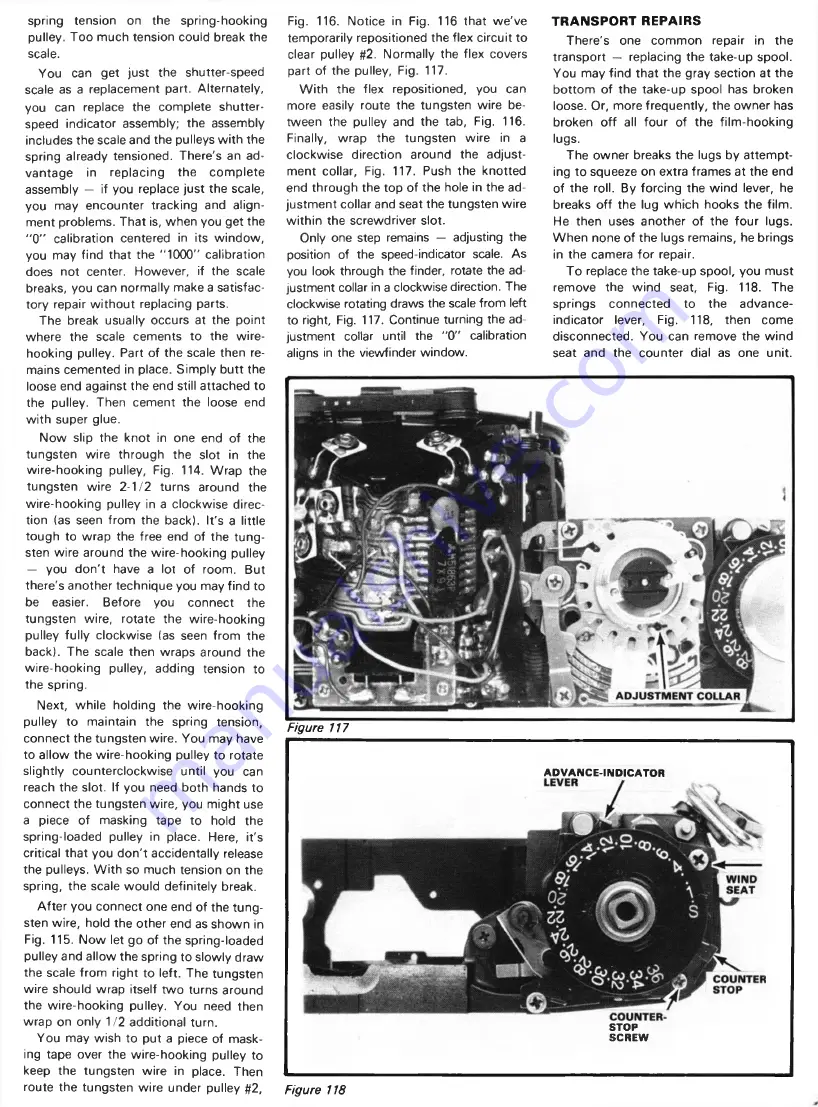

part of the pulley, Fig. 117.

W ith the flex repositioned, you can

more easily route the tungsten wire be

tween the pulley and the tab, Fig. 116.

Finally, wrap the tungsten wire in a

clockwise direction around the adjust

ment collar, Fig. 117. Push the knotted

end through the top of the hole in the ad

justm ent collar and seat the tungsten wire

w ithin the screwdriver slot.

Only one step remains — adjusting the

position of the speed-indicator scale. As

you look through the finder, rotate the ad

justment collar in a clockwise direction. The

clockwise rotating draws the scale from left

to right, Fig. 117. Continue turning the ad

justment collar until the "0 " calibration

aligns in the viewfinder window.

Figure 117

TRANSPORT REPAIRS

There's one common repair in the

transport — replacing the take-up spool.

You may find that the gray section at the

bottom of the take-up spool has broken

loose. Or, more frequently, the owner has

broken o ff all four of the film-hooking

lugs.

The owner breaks the lugs by attem pt

ing to squeeze on extra frames at the end

of the roll. By forcing the wind lever, he

breaks o ff the lug w hich hooks the film.

He then uses another of the four lugs.

W hen none of the lugs remains, he brings

in the camera fo r repair.

To replace the take-up spool, you must

remove the wind seat, Fig. 118. The

springs connected to the advance-

indicator lever. Fig. 118, then come

disconnected. You can remove the wind

seat and the counter dial as one unit.

ADVANCE-INDICATOR

STOP

SCREW

Figure 118